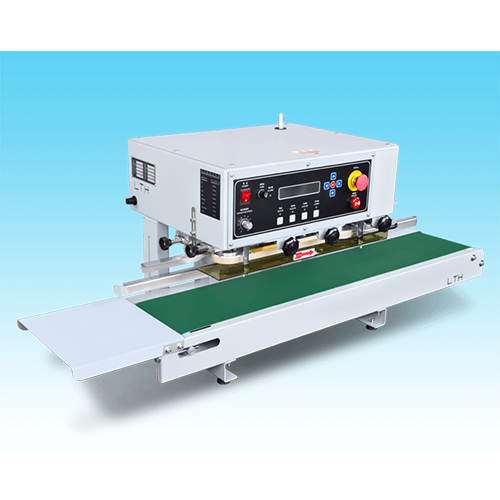

Desktop Vertical Band Sealer (SY-M904T)

Categories : Sealing Machines

1. Applications for food,chemicals and hardware parts 2. Packing materials: any heat sealable material. 3. From top of open mouth of pouch to sealing area max. Distance is 35mm. 4. Suitable for product that cannot be sealed by horizontal sealing machine. 5. Built-in counting device. 6. Built-in anomaly alarm device. 7. Built-in speed display. 8. Built-in 2 sets of temperature display, temperature control is more stable and accurate. ※Optional devices: ‧Stainless steel (SUS#304) ‧ 5-digit counter ‧Coder (solid ink or hot foil) showy

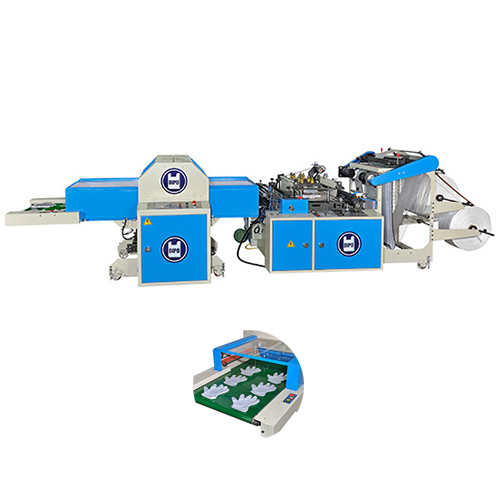

Automatic Glove Making Machine

Categories : Plastic Bag Making Machines

Fully Automatic Food Grade Glove Production Machine Fully automatic production through double line film roll feeding the full process including: seal forming – cutting the shape of the glove bag shape - Removal of waste. This automatic process gives the following benefits

DOUBLE INJECTION MOLDING

Categories : Injection Molds

Double Injection, sometimes known as 2 material 2 shot molding or 2K molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials. Through a highly specialized and automated process we carefully control the injection of multiple materials, including two different kinds of resin, into a single, multi-chambered mold. Double Injection in performed on one machine that is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle. Double Injection Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond. The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries. It also allows for molding using clear plastics, colored graphics and stylish finishes which improves your product functionality and marketplace value.

Bag With Handle Making Machine

Categories : Plastic Bag Making Machines

● Model:SPH-321S ● Speed(Cycles / Min):30-80 ● Width(mm):250-600 ● Length(mm):250-600 Produces many different types of bags with handles, such as loop handle bags, die cut handle bags, draw tape bags and patch handle bags.

HIGH-SPEED STEEL MOLD CUTTER HSP-12

Categories : Foaming Machinery

Innovative Feed Mechanism: In which, the auto up/down feed system is designed for the height of the molded material. Superb And Stabilized Dead-Point Accuracy: For which the dual-axle synchronized mechanical structure is designed to achieve higher lower dead point stability. High-Precision Depth Adjusting Mechanism: Which uses left/right synchronized fine-tune unit to achieve 0.01mm of fine-tuning accuracy. Parameter Saving Function: To name and store relevant parameters after being set. Molding Machine On-Line Function: To carry out synchronized control with other molding machine through on-line operation. Automatic Lubrication Mechanism: In which, the automatic lubrication mechanism is designed to reduce the daily maintenance work.

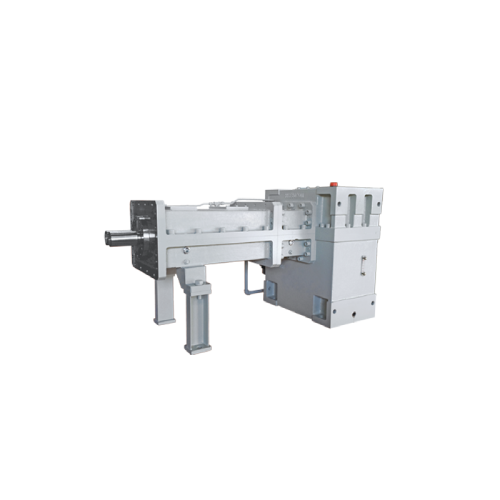

Coating Dies Slot / Slit

Categories : Extrusion Dies / Dies Heads

Slot/Slit design, excellent manifold geometry design, solvent resistant alloy, super mirror grinding technique SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid Straightness precision is made by GMA exclusive grinding technique to reduced film thickness deviation of groove width. Interchange shim for variable lip gap application. Special stainless steel resists to a full range of solvents. Work with automated controller. Manifold geometry simulation analysis technique and optimum manifold design base on customer’s material. Uniform and stable flow distribution. No coating line defect with even thickness at high speed. Professional Slot Die maintenance service by third parties is acceptable.

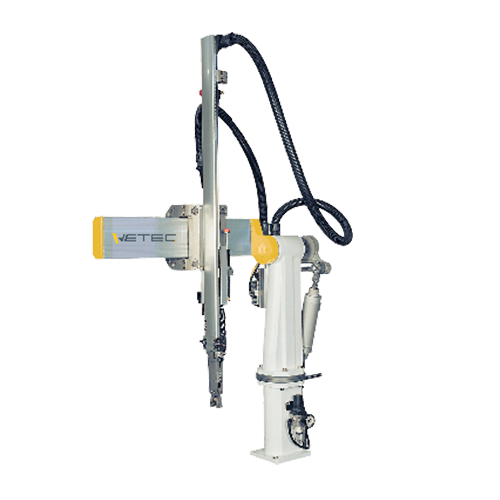

Swing Robot-W27 Series

Categories : Industrial Robots

•6 standard programs for easy set up. •25 programs for free teaching can be stored. •Hand held pendant houses a backlight LCD-display. •Error messages. •Auto-maintenance instruction requirements following a preset cycles.

PA66 (General Grade)

Categories : PA(Polyamide) /Nylon

Raw materials without adding any reinforcing materials

Dual / Two Color Injection Molding Machine DNT Series

Dual color injection molding machines are dual color demand with two injection units that enable to perform two color at one time and spare second processing time.

UNB Series-1300-1800

Categories : Industrial Robots

CE Certificate Rubber Back-Injection Molding Machine

Categories : Rubber Injection Molding Machines

A special design of two-stage material supply is adopted. It expels bubbles out of the raw material in the most effective way and there is no dead material.

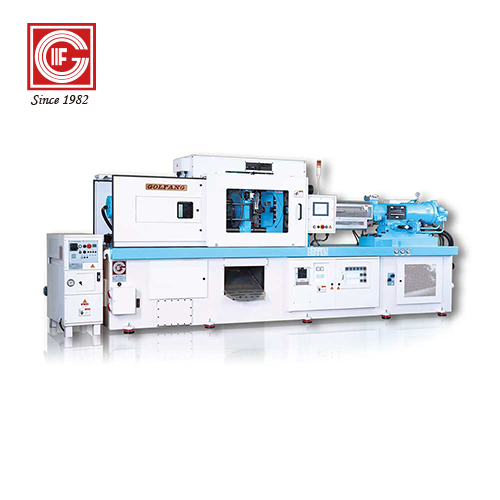

Single-Stage Injection Stretch Blow Molding Machine - ISB Series

Categories : Injection Blow Molding Machines

GF/ISB series adopts the world's most advanced single-stage injection stretch blow molding machine technology. One single machine is able to achieve high quality and efficient productivity. Compared with two-stage PET machines, GF/ISB possesses several advantages. Golfang

Multiple Embedded Rotary Injection Molding Machine-YR Series

Categories : Vertical Injection Molding Machines

• Vertical clamping with vertical injection. • Rotary table oscillate 180 °, rotate back / forth for easy loading and finished parts pick out, to increase productivity. • Rotary table with location pin, accurate positioning for mold alignment and automation. • Robot interface capability for complete automation. • Standardized wtih 2-sation function, and capable for 3-station or 4-station function & automation linkup for advanced efficiency. • Standardized wtih 3-column clamp, and available for 4-column clamp upon request.

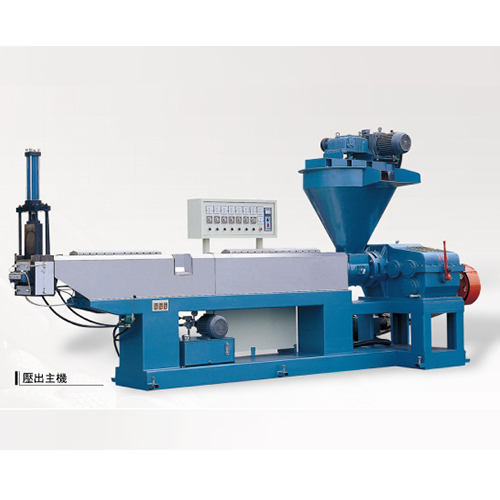

Twin Screw Extruder - Counter Rotating Type

Categories : Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

Sheet Extruding Machines - HC-100PLA-1000

Categories : Film and Sheet Extrusion Lines

Although the material of PLA is similar to plastic, it can be decomposed thoroughly in compost. Due to its high transparency and water-resistance.....

OSCILLATING TOWER ABC THREE-LAYER BLOWN FILM MACHINE

Categories : Blown Film Extruders

The ABC three-layer co-extrusion machine is your ideal choice for producing high-end plastic products, such as shrink films, agricultural mulches, electrical insulation films, packaging films, medical packaging films, stretch hood films. The raw material formula for each layer can be customized respectively according to your requirements. The oscillating haul-off unit provides excellent film gauge randomization, ensuring the production of high-quality and wrinkle-free films. The oscillating haul-off unit is also rather durable, and its equipment lifespan is much longer than the rotary die. Suitable for producing three-layer films for specific functions Recycled materials or CaCO3 is applicable to the middle layer in order to save material costs Die and air-ring specially designed for producing high-quality three-layer films 360° Oscillating Haul-off unit improves film thickness uniformity EPC (Edge Position Controller) Full customization according to your specific requirements

PSM - 8 Cup & Tray Automatic Filling & Sealing Mac

Categories : Sealing Machines

Cup dispense-filling-sealing machine be demanded on high speed and availability. High accuracy assembly construction requires to satisfy customer's product can be achieved perfect sealing and CIP system available to achieved hygienic required. Research and innovation more harmony human operation environment from construction design until assembly works all requires consistence and useful to reduce customer's machine breakdown cost. Jelly, pudding, cream, cup water, cup noodles, snack, soup, ice cream, rice cake, cosmetic, juice, and other daily foods.

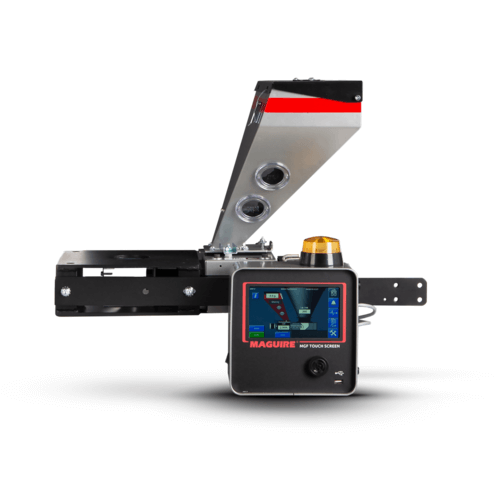

MGF Gravimetric Feeders

Categories : Dosing and Measuring Equipment

Robust hardware, integrated with industry-leading software control to achieve repeatable consistent dosing accuracy. Unique twin load cell technology Dosing accuracy ± 0.2% on 1% setting Feeder ideal for all molding and extrusion processes

Single-Stage Injection Blow Molding Machine - IB Series

Categories : Injection Blow Molding Machines

Advanced Single Stage Blow Molding Machine Commonly used in the production of pet bottle, the mechanical design of Golfang Single Stage Blow Molding Machine is based on the blueprint of the world's most popular machine- the plastic injection machine with pressure booster ram system. Solid construction, durability, high precision, high stability, easy operation, easy maintenance and low running cost.

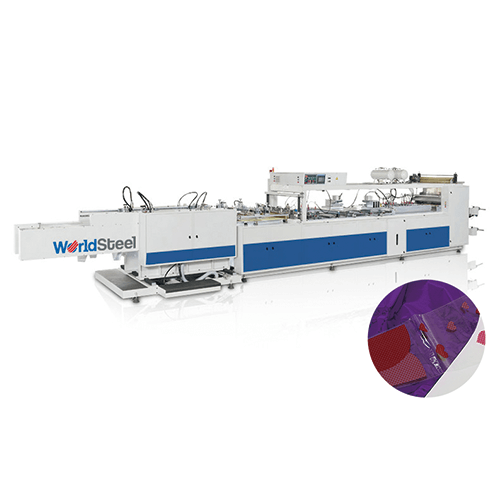

Flower Shape Bag Making Machine

Categories : Bag Making Machine by Applications

The World Steel flower sleeve bag making machine can be used for more than just flower bags. Coupled with our perforation machine, punching system and specialized parts it can also be used to make umbrella bags, sandwich bags and many different types of packaging.

Other Auxiliary Equipment

Categories : Control Equipment

Develop control system of other plastic machinery, such as extruder, bottle

Vertical Type Continuous Dryer

Categories : Dryers and Dehumidifiers For Plastic Materials

High efficiency dryer continues feeding wet materials and continues discharging materials improving traditional dryer to dry wet materials by lot saving your time and cost.

Polyamid 6 - NA1200GH50

Categories : PA(Polyamide) /Nylon

Glass fiber 50% reinforced, low warpage, high modulus, high impact. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

UZSII-800/1000W

Categories : Industrial Robots

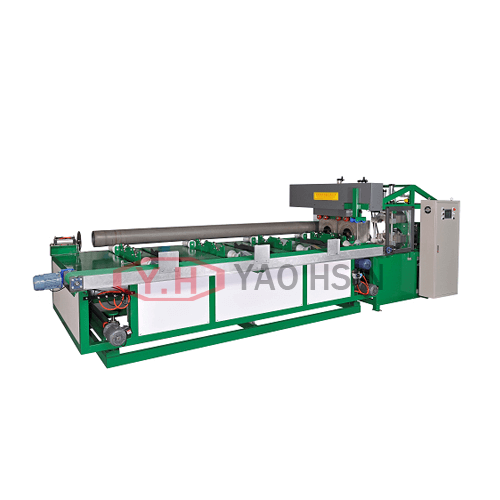

Flame Laminating Machine

Categories : Extrusion Lamination Machines

The SA-6AF flame laminating machine is laminating equipment for laminating foam sheet with various type of fabrics by using gas burner. The burner installed over the whole working width and melts the surface of foam to be contact with the carrier material and produces like an adhesive on the surface for laminating. laminating foam sheet with various type of fabrics

PP Woven Bag Related Machinery - JLVFM-SERIES

“ L ” cutting unit Valve forming unit Display screen operation interface

Motor with Gear Box

Categories : Motors

AC Small Motor with Gear Box -K Series】 This is a AC small motor combined with a gearbox. The motor is from 6W to 150W, and is used with the gearbox. The standard ratio of gearbox is from 1/3 to 1/180. If the gearbox ratio does not meet the requirements, you can replace the gearbox simply. The products are divided into single-phase motors equipped with capacitors or three-phase motors. The installation is simple and easy, so they are mostly installed in conveyor belt, packaging machine, food machinery, pharmaceutical machinery, automation machinery and other equipment. You can also choose AC small motors certified by UL or CE standards.

Secondary Packaging - Cartoning - CSC-50

Categories : Cartoning Machines

The cartoning equipment applies the vertical semi-automatic production operation. The equipment is suitable for more types with medium capacity products

ABA Blown Film Machine (JC-ABA Series)

Categories : Co-Extrusion Blown Film Machines

JC-ABA Series - 3 layer Co-Extrusion Blown Film is the ultimate solution producing high quality film at lower production cost. The ABA 3 layer co-extrusion line consist two high performance extruders with a 3 layer ABA co-extrusion die head. The outer layer is dominantly with virgin materials, and the core layer with large percentage of CaCo3 or in-house recycled pellets material. Further the ABA 3 layer blown film structure also persist higher strength characteristic than conventional monolayer film, which overall gives an advantage to the competitive market.

Polyamid 66 - NB1200GH50

Categories : PA(Polyamide) /Nylon

Glass fiber 50% reinforced, low warpage, high modulus, high impact.

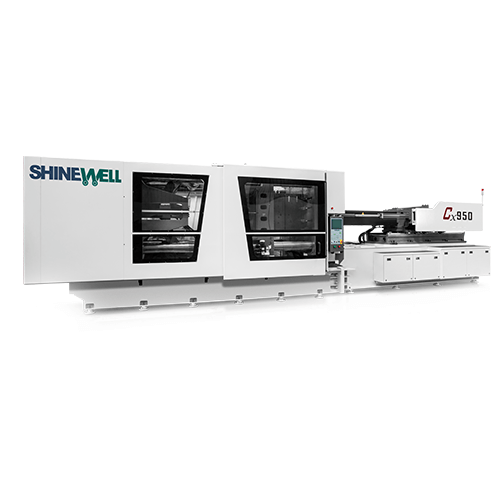

Servo Energy Saving Injection Molding Machine CX-60 – CX-1600

Categories : Horizontal Injection Molding Machines

APPLICATIONS:Packaging,Optics,Electronics,PET Preform,Closures,Cutlery,Thin Wall,Automotive

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

P-20

Categories : Injection Molds