Classification : Blown Film Extrusion Line

Country: Taiwan

Phone: 886-5-2376175

Fax: 886-5-2376176

Contact Person: Tony Wang

|

• Express Bag |

• T-shirt Bag |

|

|

• Plant Bag |

• Laundry Bag |

|

|

• Shopping Bag |

• Garbage Bag |

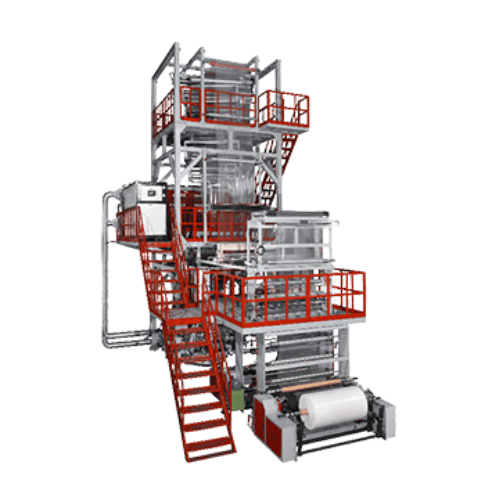

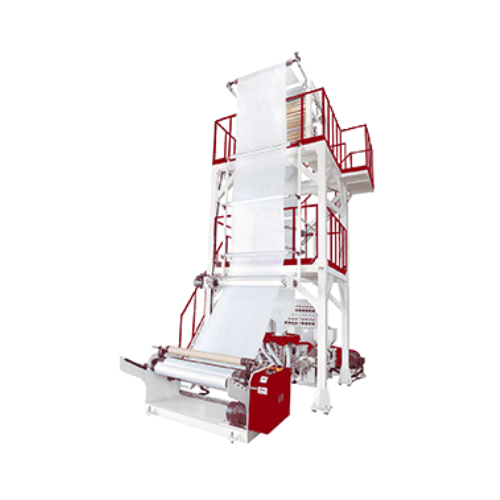

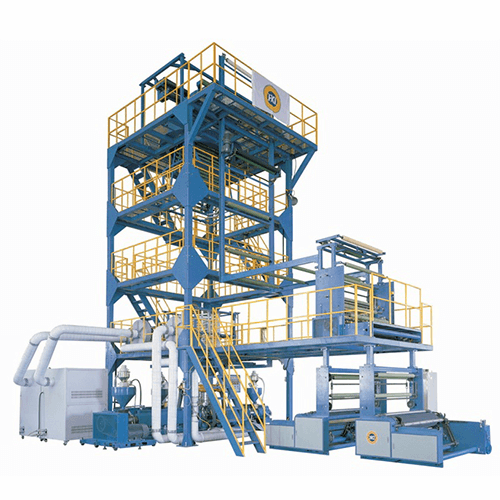

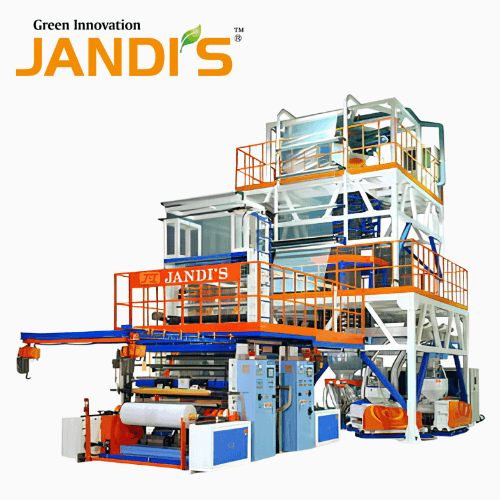

JC-ABA Series

ABA Blown Film Line

-

Our JC-ABA Series of 3-layer co-extrusion blown film lines are the ultimate economic and environmental solutions for multilayer blown film production.

-

JC-ABA Series lines are powered by two high-performance extruders and a specialized 3-layer ABA die head. The outer A-layers are produced with virgin materials, while the core B-layer is composed of a high-concentration CaCO₃ or recycled pellet material blend.

-

The resulting ABA 3-layer film is a uniquely competitive and useful product, as it is stronger and can be more visually appealing than monolayer film while also being more environmentally-friendly and cheaper to produce than traditional multilayer film.

| MODEL | JC-ABA900 | JC-ABA1100 | JC-ABA1300 |

| Applicable Materials | LDPE / LLDPE / MDPE / HDPE | LDPE / LLDPE / MDPE / HDPE | LDPE / LLDPE / MDPE / HDPE |

| Screw Diameters* (mm) | 45 / 55 | 50 / 55 | 55 / 75 |

| Film Layflat Width* (mm) | 800 | 1000 | 1200 |

| Film Thickness* (mm) | 0.015 - 0.10 | 0.015 - 0.10 | 0.015 - 0.10 |

| Extrusion Capacity* (kg/hr) | 100 | 160 | 250 |