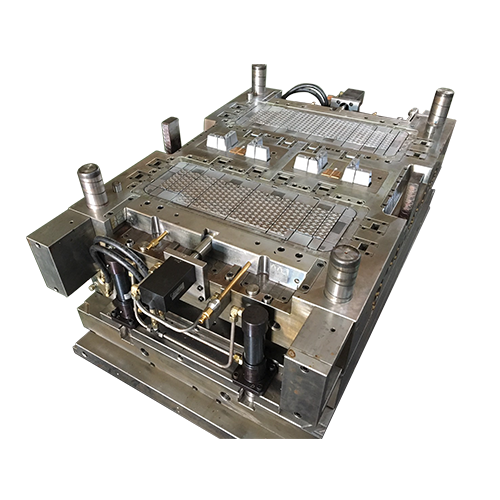

Rattan Mold

Categories : Injection Molds

Applications: Air filters Closet Hangers Toilet Stool Mold size: 990W x 1720L x 860H mm Mold weight: 9500kg Injection machine: 1000TON

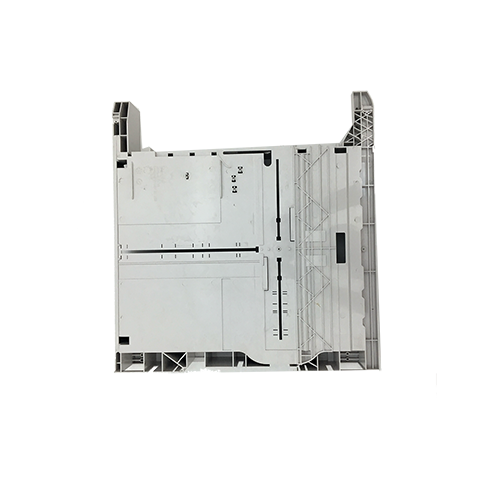

Home Appliance Mould / Rattan Mould

Categories : Injection Molds

The appearance of surface mainly finished in texture or plating. Meet customer high requirements for product fitting. Applications: TV Frame Desktop Frame Rattan Furniture Treadmills for running

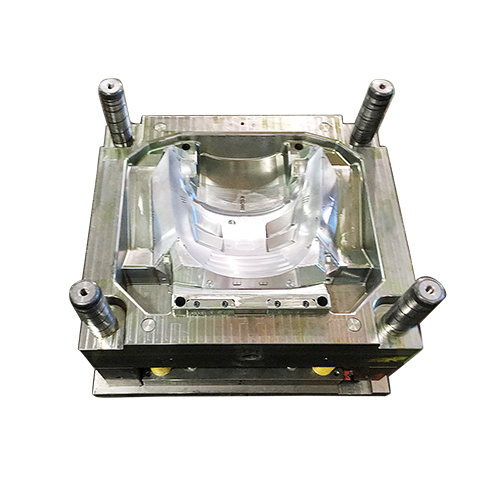

Motorcycle Injection Molds

Categories : Injection Molds

The appearance of surface mainly finished in texture or plating. Meet customer high requirements for product fitting.

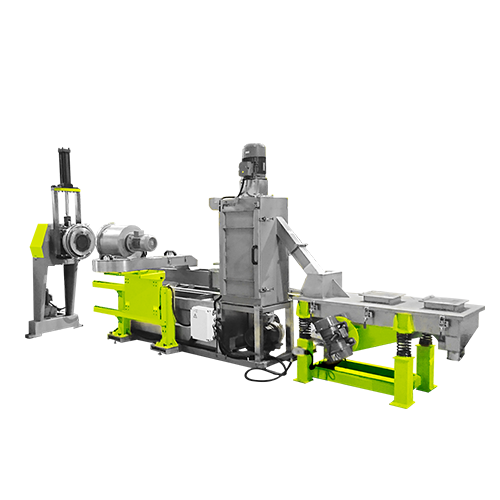

HF-S SERIES: Single Screw Pellet Extrusion Machine

Categories : Plastic Pelletizer Machines

Mainly apply in the thermal polymer compounding field, and we can design a production line to meet the needs of customers in the pelletizing, plate, film, and pipe extrusion. Applicable materials : PE、LDPE、LLDPE、HDPE、PP、PET、PS、PA、BOPP、 ABS、PEEK、TPU、TPV、TPR、RUBBER、FEP、SMA

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

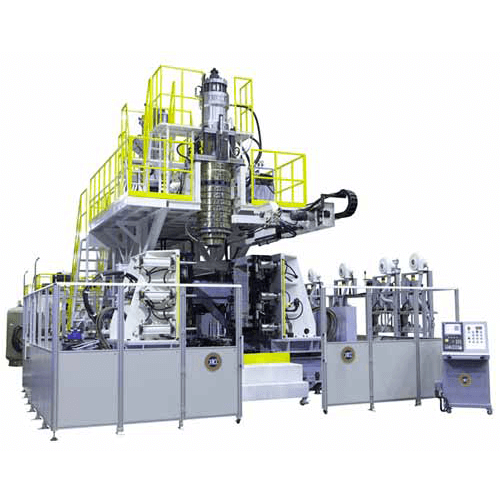

Accumulator Head Blow Moulding Machines-L Ring Drum

Categories : Extrusion Blow Molding Machines

FKI offers the most practical Accumulator Head Blow Molding Machine for the industry with a wide range of applications: Cooking oil containers: from 10 to 30 liters Chemical use jerry cans: from 10 to 60 liters Open top drums: from 30 to 220 liters Closed head L Ring drums: from 120 ~ 220 liter, 1,000 liter IBC, air ducts, automobile components, tables, tools boxed, water vessels, furniture board and any other hollow-shaped articles as per requirements.

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

Strand Pelletizer-PSH

Categories : Plastic Pelletizer Machines

The PSH strand pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Strands from the extruder are pulled through a water-filled cooling bath and blown dry by an air knife before entering the pelletizer. This simple pelletizing process is applicable to many different types of plastics and rubber. Our knives are made with tungsten carbide steel to ensure a long life and clean cuts. Puller and rotary knife can be synchronized to ensure uniform pellet size regardless of the extruder throughput. Designed with built in safety features, the moving parts are all enclosed within a protective cover.

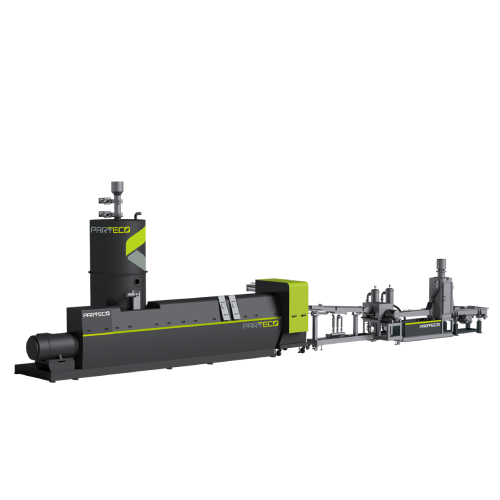

Granulating System: Strand Pelletizer

Categories : Plastic Pelletizer Machines

Advanced strand pelletizer for most plastic materials. Specialize in manufacturing of the plastic strand pelletizing system. PARTECO plastic granulating machine is applicable to most of plastic materials. Suitable for most plastic materials.

Hot Die Face Pelletizing System

Categories : Plastic Pelletizer Machines

Cost Reduction The molten polymer from the extruder is passed to the die head. A rotating blade cuts the hot material as it exits the die hole and falls into a water ring for cooling. The operator does not need to draw the strands, which reduces the lump waste during re-drawing. More Uniformity, More Profit The pelletizing cutter is a universal joint design. The cutter adjusts the blade automatically during operation. Final plastic pellets are in uniform size in order to be sold at a higher price and bring you more profit.

Granulating System: Water Ring Pelletizer System

Categories : Plastic Pelletizer Machines

Structure and function of our plastic water ring pelletizer system and machine. Features and advantages of our plastic water ring pelletizing machine line. Applicable plastic materials of our plastic granulating series system and machine. Mainly used for plastic materials such as LDPE、HDPE、PP etc.

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pelletizer Machines

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly applied to the processing of PET crushed chips recycled from PET bottles. By means of vacuum degassing system to remove the water and impurities, then go through the melting extrusion, filtering and granulating process to tailor made the complete PET recycling solutions for you. Applicable materials Film or Flakes : PET Bottle Flakes