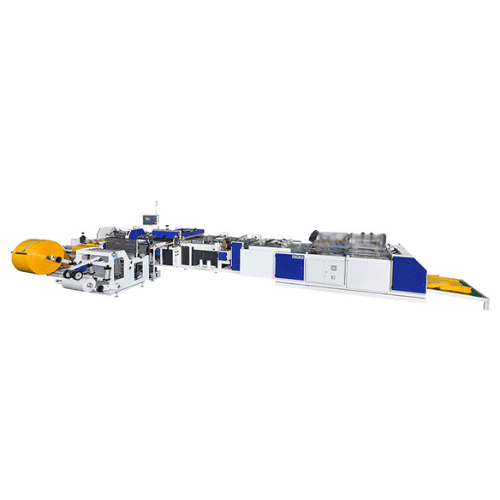

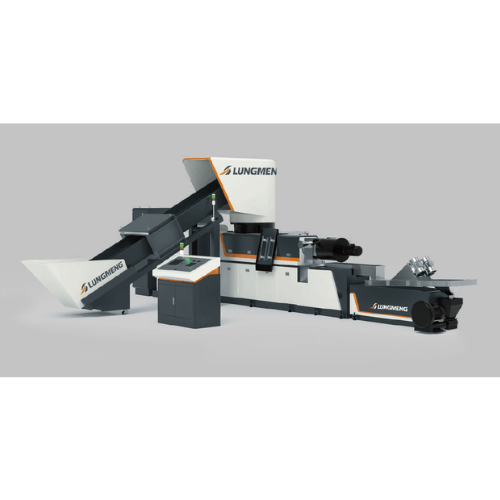

PP Woven Bag Fully Automatic Liner Inserting – Bag Top Heming Conversion Line: Liner Hemming

Categories : Woven Bag Making Machines

All-In-One Multi-Functional Machine - Flexible Usage for Various Type of PP Woven Bag Processing On The Same Machine. Available for Woven Bags: With Liner Inserting-Cutting-Sewing and Bag Top Hemming Process With Cutting-Sewing and Bag Top Hemming Process Only (Without Liner Inserting) With Liner Inserting-Cutting-Sewing Only (Without Bag Top Hemming Process) Cutting-Sewing Process Only (Without Liner Inserting & Without Bag Top Hemming) Saving Manpower, Space and Saving Cultivated Training for Skilled Manuel Operators to the Maximum. Producing Finished Bags with Conformed & Unified Quality with Stable Performance. Experiencing Clean Process of Bag Top Hemming. Largely Reducing Hand-Touching on the Bag Top Area. Highly Synchronized Machine for Easy Setup and Quick Bag Size Changeover. A Total-Solution Machine for PP Woven Bags with Final Products Applicable in a Big Variety Market.

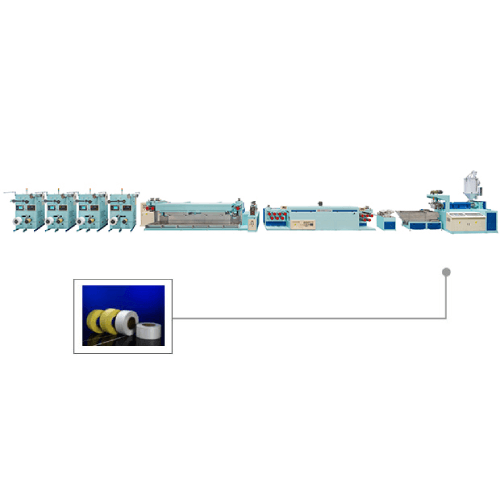

JS 239HA4 PP Strapping Band Making Machine

Categories : Tape Extrusion Machines

this pp strap production line is mainly used to produce pp strap, equipped with german gear pump, features oven stretching 10 times, pneumatic embossing, anealing and cooling. this pp strap production line also has a function of plc winders, which makes operation very convenient.

Vertical Batch Mixers - SVM-U

Categories : Mixers and Blenders

SVM-U is mainly used for mixing plastics as raw materials, masterbatch and recycled materials. SVM-U can not be used dealing with plastic powder and all kinds of foods, chemicals, and inflammable, explosive and volatile materials. Bulk density should be taken into account when the dimension of material is uneven or in other forms.

Servo Power-Saving Injection Molding Machine (HT Series)

Categories : Automatic Injection Molding Machine

It is standard and conventional equipment. The applicable industries include general household hardware products, electronic device housings, such as multifunction printer, laser printer or computer parts. It's also suitable for automotive parts, general lenses, and frames, etc.

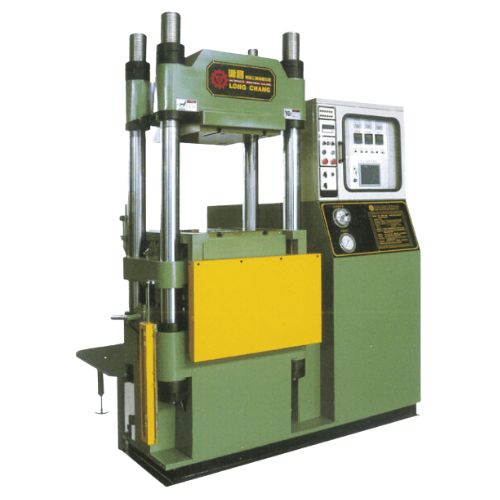

Single Body Oil Hydraulic Compression Molding Machine of Break Pad - FC-D Series

Categories : Compression Molding Machines

APPLICATIONS: For automobile, motorcycle , truck, train any kind of butterfly and drum type of friction break lining products.

Master-batch Feeder (MF)

Categories : Feeders

The masterbatch mixes with your virgin resin at the machine hopper automatically. You don't need to pre-color nor pre-mix your resin anymore. It saves the manpower, resin, stock costs, and keeps working environment clean. The unit mixes and doses masterbatch, additives, free flowing powders, regrinded and virgin resin to ensure consistent and accurate mixing which results in better quality of product and less rejects. With the special process, the internal part of the unit has no dead corners and makes the dosing process more accurate. Both dosing-cylinder and dosing-screw can be easily changed. The motor feedback control is operated by the tacho-generator which will not be influenced by power fluctuations. It gives the utmost accurate dosing. If some reasons changed R.P.M. of the extruder after setting, the unit will automatically to be changed by the percentage of new R.P.M. By just entering the weight of the materials, screw back time, dosing capacity per turn and additional rate of the masterbatch, the CPU will calculate proper R.P.M. rate automatically. The control panel is user friendly & much more accurate. Besides, it also has the function to store up to 10 sets of R.P.M. setting. To work with the injection molding machines, the unit is also equipped with a timer to control the dosing time.

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Side feeding barrel is better for storage and steady material input at same time. Main Extruder can extrude the material whose moisture below 7%. Sub extruder conducts second time filtering and ventilating for dirtier materials. Die face cutting frame made in SUS304 to prevent the rust and corrosion. Knives adjustments automaticlly patent design.The knife and die plate always set at 90 degree. No need to adjust frequently. High speed dryer is soundproof with double layer sealing design. The underneath water tank can gather the waste water and filter the impurity. Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryer. The triple layers vibrating screener is easy to clean, disassemble and assemble. Can customize the diameter of the hole. Blower with noiseless design. Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

Plastic Recycling Machine - Gator Series

Categories : Plastic Waste Recycling Machines

Applicable materials : HDPE , LDPE and PP. Designed for high material process stability and production. Vent design on the barrel evaporates the volatiles from the recycled material. Hydraulic screen change unit and pressure gauge for easy operation and safety. Water chamber with die face cutter simplifies the process. Easy operation, low downtime and quick maintenance.

Crushing Machine For Immediate Recycling System - C-200 / 250 / 300 ST

Categories : Plastic Crushers

The plastic crusher is design for plastic manufacturing. Industrial recycling and granulation of plastic. • Suitable materials include plastics such as PP, PVC, PE, PET, ABS, etc. • Applicable fo...

Cabinet Dryers - CD

Categories : Dryers and Dehumidifiers For Plastic Materials

CD series of cabinet dryers are mostly used for simultaneous drying of different kinds of polymers in small quantities or for drying materials for trial molding. They can also be applied in electronic engineering, electroplating, pharmacy, paint baking, printing industries, etc. for preheating or drying related products.

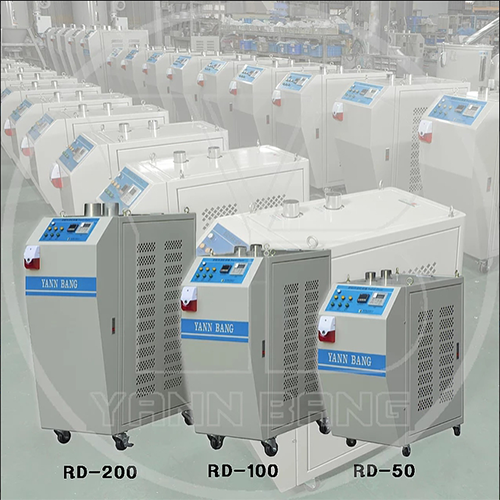

Rapid Dryer (RD)

Categories : Dryers and Dehumidifiers For Plastic Materials

Without replace your old hopper dryer, use this new dryer to dry faster with better quality and to upgrade production more efficiently. 1. Wide application. Suit to numerous material such as PC, PMMA, PA46, PPS, NYLON and some PET/PETG. 2. Save time and energy. Patented technology significantly shortens the drying time. Normally NYLON takes four hours to dry. Work with Yann Bang’s rapid dryer (RD), it only takes two hours to dry completely and ready to use. RD can decrease 50% of drying hours and save 50% of energy for you. 3. Upgrade energy save. Combine with Yann Bang’s Energy-efficient Hopper dryer can save more energy obviously. 4. Increase yield rate of output. Moisture content can be reduced to 0.02% (depend on the initial moisture content of resin), improve the drying quality of resin, and lower defective products. 5. Easy maintenance. Install with plug-in air filter and dust collector (oil collector) that you can unload easily to clean and replace parts.

Energy-Efficient Hopper Dryer(G series)

Categories : Dryers and Dehumidifiers For Plastic Materials

Awarded patents in Germany, Taiwan and China, the advanced technology recycles internal heat and faster heating. That saves your energy over 30% and extend equipment life time. Work with a dehumidifier can save more! The temperature inside hopper increases quickly for better drying and shorten above 30% of drying hour. Simultaneously HEI can separate dust and oil for better quality. An energy-efficient device can save energy and improve working environment for you.