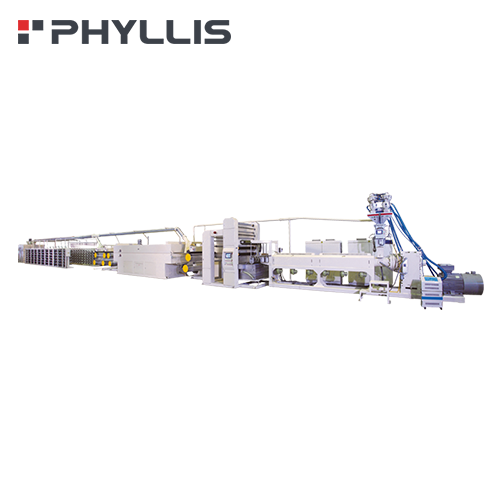

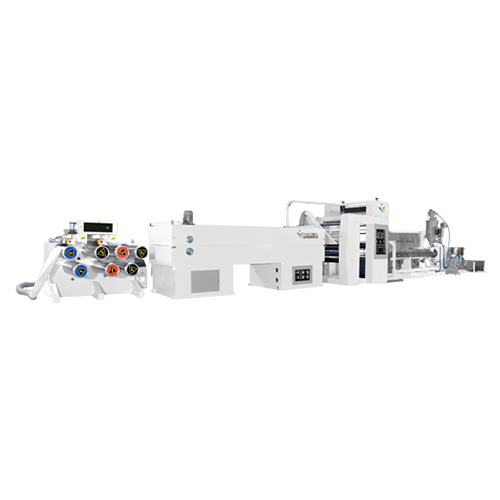

Extrusion Tape Line (FIBC Tapes)

Categories : Tape Extrusion Machines

One layer extrusion tape line specially designed to produce PP tapes for high performance application at premium quality mainly used for FIBC fabrics, and various technical applications.

HA series - 950SW

Categories : Industrial Robots

3RT Mold-Open Rubber Injection Molding Machine IRH-S3

Categories : Rain boot Injection Molding Machines

Mold opening design The 3RT surpasses the traditional top opening mold that can be used for the triple or four molds with the design of the opening mold and pushing out the mold in the between. The opening mold can be adjusted by the software with separate opening, separate pushing out the mold in between, continuous opening and continuous pushing out the mold in between. Injection volume control High precision optical ruler is adopted for precisely calculating and controlling. Design of rotary injection board Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable. Safety design A high-tech infrared safety electronic sensor and automatic warning system are adopted to monitors the status of machine in order to provide extra protection to ensure the operation safety for operators. Hydraulic system Design Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously.

AUTOMATIC TYPE SEALING MACHINE-ET-22

Categories : Sealing Machines

1. PLC with Index Gear Conveyor, Inverter Speed Control and Touch Screen Operation. 2. Stainless Steel frame and Anodized Aluminum.

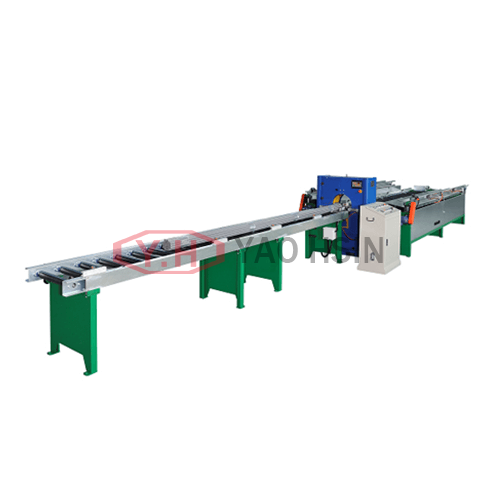

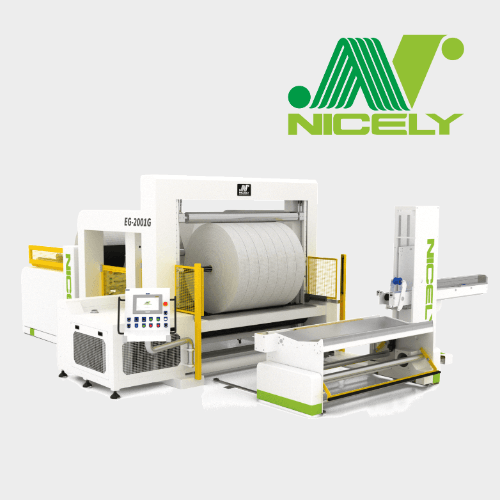

Auto Circular Horizontal Cutting Machine

Categories : Foaming Machinery

For cutting Flexible PU foam block with density under 50kg/m3, rebonded foam with density under 80kg/m3 and open celled PVC foam.

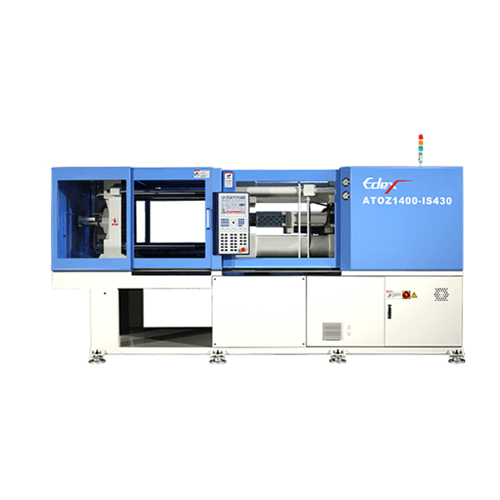

Hydraulic Clamping Injection Molding Machine (HCV Series)

Categories : Horizontal Injection Molding Machines

• New hydraulic clamping mechanism is with integration high pressure cylinder and prefill valve at top end which is to raise up the locking pressure much faster , also fast speed for mold closing and opening . Whilst , solid mechanical design provides much stronger rigidity of mold platen and ensure the high accuracy of molding products . • Linear transducers for Clamping , Ejection and Injection strokes , accurate and easy in operation . • Adopted the high efficient Japan made servo system ( DAIKIN SUT SYSTEM) which is with pressure transducer to detect and feedback , also the encoder behind motor will calculate and provide accurate oil flow to achieve CLOSE LOOP control . SUT system can provide excellent response time ≦ 0.07sec , repeatability ≦ 1% and linearity ≦ 1% . • With diagonal dual carriage cylinders to enforce the nozzle holding force . Liner rails with ball bearings supports whole injection unit to reduce the mechanical resistant and accurate the injection control. • Digital type back pressure control. • Ion nitrided screw and barrel sets are with long working life .

HIGH ACCURACY POLARIZER CUTTER TRC-1200

Categories : Cutting Machines

Stable Bottomdead Center Accuracy: The delicate-design mechanism can maintain the stable bottomdead center accuracy under high speed cutting running. Knife Height Adjustment Mechanism: When setting up knife mold, the instrument of the machine can make right and left adjustment respectively as well as complete the setup of knife mold clearly and rapidly. Easy-Operate Operation Panel: This machine adopts new touch screen featuring affinity operation interface that makes an easy operation, thus lowering cost for employee training. Accuracy Delivery Mechanism: Oaded with new mechanism, the delivery move volume digital setup, it achieves a stable an accurate delivery function. High Speed Cutting: The strengthened-design mechanism can allow high speed cutting. High Torsiodamper: With the strong rigidity of the unit, noise can be maintained within the standard value under high speed running.

VALVE GATE-AVMT

Categories : Hot Runner Systems

Suitable for large-scale parts or complex shape parts. There is a pin in the nozzle and drive by pneumatic or hydraulic to open or close the nozzle gate. When the valve pin open / close can control the melt filling. Especially for the big gate design, the valve pin will seal the gate after packing process to prevent the stringing and get the unapparent gate mark. For the multi-gate mold design, using the sequence control can eliminate the weld line problem.

P-09

Categories : Injection Molds

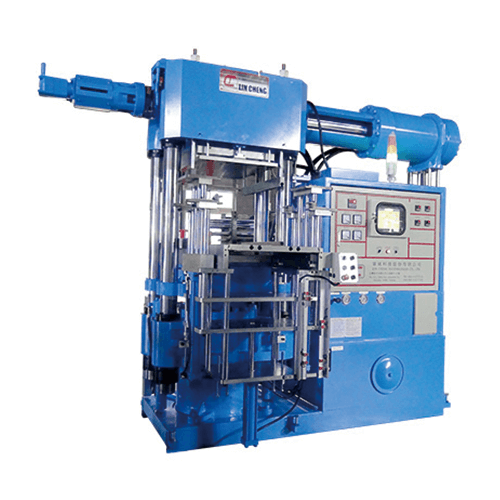

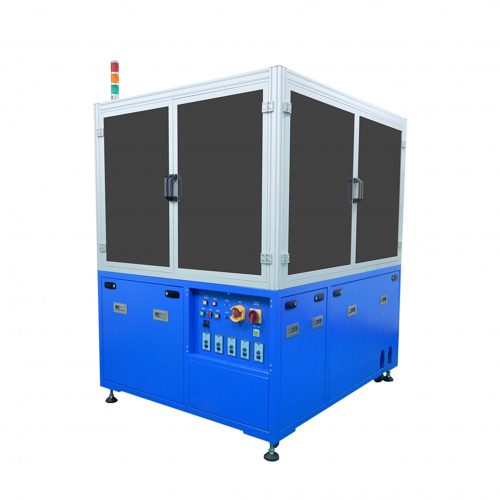

CE Certificate Compression Molding Machine

Categories : Compression Molding Machines

Safety design Mold lifting design Hydraulic system design Mold calibration Mold position

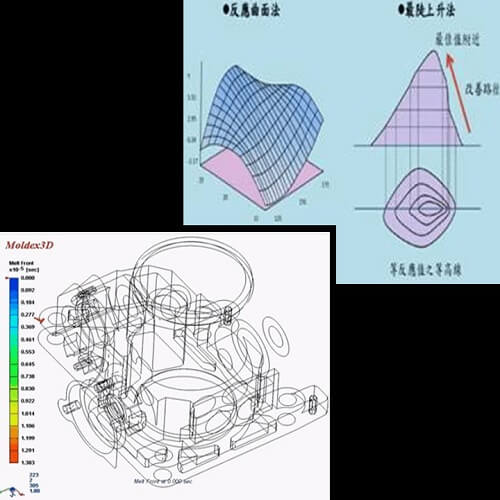

PROCESS OPTIMIZATION

Categories : Injection Molds

In-Mold Decoration (IMD) is an efficient, durable and cost effective technique for printing, painting, and forming plastic decorations. However, a large number of parameters involved IMD manufacturing processes and the complex relationship between these parameters make the determination of the optimal parameter setting a challenging task. This paper proposes a systematic framework integrating Response Surface Methodology (RSM) and logistic regression to improve the yield of IMD manufacturing process. The integrated framework becomes easy to identify the optimal parameter setting,saving a great deal of time and money in the manufacturing process. On the empirical study in collaboration with Yomura, the proposed framework shows the significant result from 10% to 87.5% validating the viability of the proposed framework in real setting. (Key words: IMD, In-Mold Decoration, Parameter Optimization, RSM, Response Surface Methodology, Logistic Regression) EXPERT ANALYTICAL SYSTEM Yomura Technologies employs state-of-the-art technologies to select materials, validate component designs, develop tool designs and optimize its processes, ensuring that innovative concepts are achievable at the lowest cost of production. (Keywords: Moldex3D, Moldflow, PowerMill Pro, CAD system)

P-16

Categories : Injection Molds

TWO-COLOR CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Equipped with 2 extruders, A/B type blown film machine is able to produce two layer/two colours film. This machine can produce two-color-striped films. Final products have obvious streak of two separate colors. Upgrade die and air ring to produce HDPE and LDPE 2 layer film.

Dual Injection Low Pressure Molding Machine

Categories : Low Pressure Injection Molding Machines

Low pressure molding leads the way to protect fragile electronics components against moisture, dust-proof, moisture proof, insulation, temperature resistance, flame retardant, vibration reduction, well bonding, waterproof etc. Suitable for electronic components such as micro switches that require waterproof function, automotive electronic sensor.

Corrugated Medium Liner / Medium Fluiting / Test liner

Categories : Cartoning Machines

- Our main products are Corrugated Medium Liner (GSM 112 to 150), Medium Fluiting (GSM 112 to 200) and Test liner (GSM 125 to 200). - Main applications for manufacturing paper carton box and paper bag. - Paper jumbo roll width can be slit as per required width. Maximum 4 meter wide.

Multi-Axle Auto Film Bonding Machine AFC-700LE

Categories : Cutting Machines

Patented Bonding Mechanism: In achieving higher bonding accuracy and without air bubbles. Fully Automatic Tension Control System: The tension of materials for each axle is controlled in an automatic way. Servo Transmission Control: Dual-Axle servomotor is used to achieve synchronized alignment control. Diversified Size Option: The parameter fine-tuning can be executed according to the characteristics of different materials. High Clean Bonding Environment: Which meet high-cleanliness bonding space requirements in providing higher Y-Rate. Unique Material Handling Techniques: Which is designed according to the characteristics of optical film to avoid scratching the material.

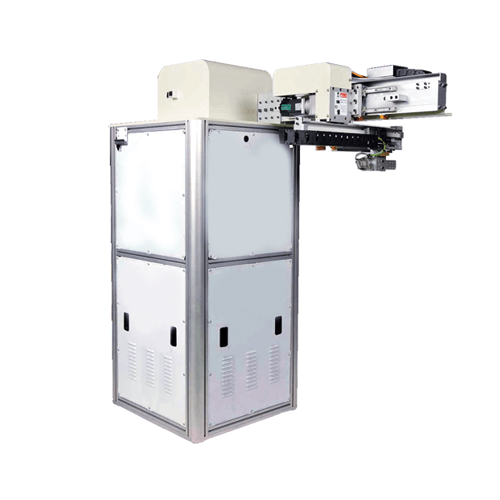

ZH

Categories : Industrial Robots

•Servo motor controlled, side-entry robot, best accessor of rapid molding. •Two axis servo motor. •Bearing linear guide system, more stable and durable. •Molded parts with artistic appearance more accurate and smooth movement.

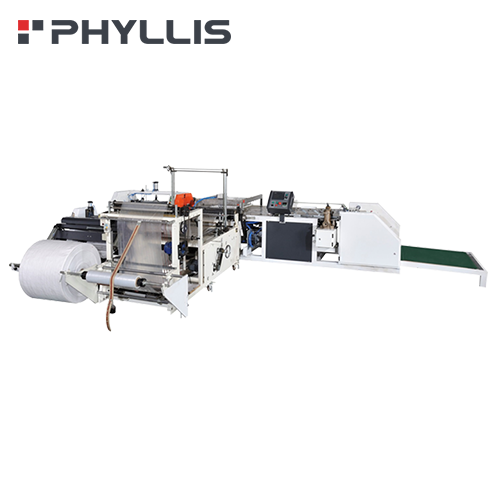

Flat Yarn Making Machine For Jumbo Bag

Categories : Extrusion Lines For Filaments and Yarn

Function: It can produce flat knitting yarn with high tannin number. It can be used for knitting tonnage bags with high strength and low elongation, and provide the required number of ingots according to customer's demand.

O-Ring Auto Optical Inspector

Categories : Inspecting and Testing Equipment

O-Ring Auto Optical Inspector Rubber O-Ring Silicon O-Ring

All Electric Machine With SPARK Series

Categories : Automatic Injection Molding Machine

Features: Combining ultra-thin high speed and ultra-thick low speed Revolution round template design with Japanese super rigid frame Super high-speed intelligent computer controller With Japanese screw design, excellent performance All-electric machine vs. Hydraulic machine More environmentally friendly → Reduce the configuration of cooling water circulation system More energy saving → No need high-watt electric source. More environmental cleanness → No oil leakage concern and no hydraulic oil consumption. More quiet → No high speed sound driven by oil pump. Easier to execute the machine compounding action → difficult for hydraulic machines. More sensitive for mold low pressure protection → avoid damage to mold.

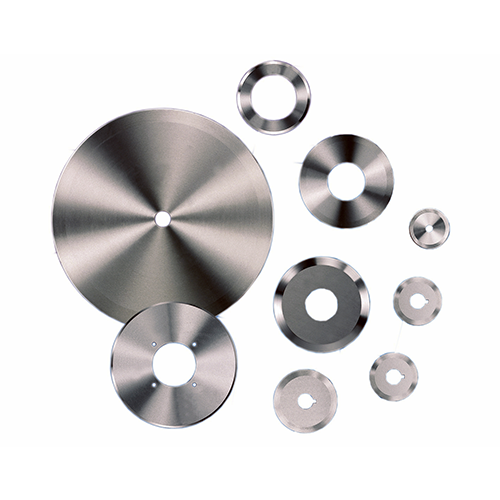

Flat Circular Knife

Categories : Industrial Knives

Guillotine Knife

Categories : Industrial Knives

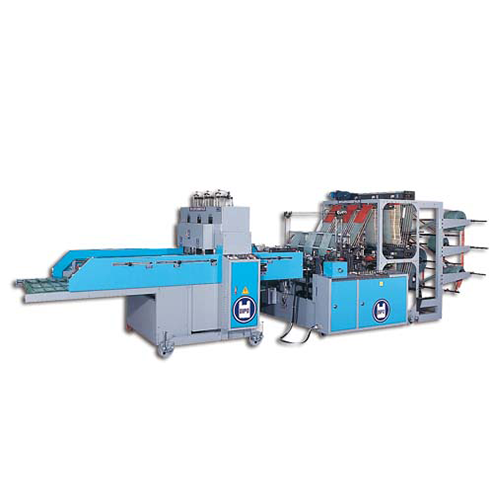

Double Layer High Speed Multi Lines/T-SHIRT Bag Making Machine-KDP-SERVO-Series

Categories : Plastic Bag Making Machines

● Ldeal for sealing and cutting super-thin bags as well as T-shirt bags. ● Electromagnetic clutches and breaks ensure accuracy of bag sealing and cutting.

PP Tape Line Making Machine-TY-TLM Series

Categories : Extrusion Lines For Filaments and Yarn

TLM series is an economical design of extrusion tape line, and low power consumption produces high performance as the main feature.

SFX-The Room Saving Press

Categories : Flexographic Printing Machines

The SFX is an environmental friendly press that could run on water based inks. With SFX, you could obtain the closest print quality to a central impression press. If you are looking for a room saving option with decent print quality this is the press for you to customize

Liner Insertion Conversion Line

Categories : Bag Making Machine by Applications

Innovative design for inner liner inserting-cutting-sewing in one process.

PET Stretch Blow Molding Machine - TEM08S2

Categories : Automatic Blow Molding Machines

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Horizontal Bag Filling & Sealing Machine

FEATURES : 1. Design for the most versatile packing applications. 2. The outer structure of machine is shielded with SUS304 stainless steel for ease of cleaning and maintenance. 3. Fitted with automatic weighing, filling machines, date corder, and conveyor (optional) to suit various materials. 4. Rated weigh within 2000 Grams per bag. APPLICATIONS : Juice, Jelly, Plum Jelly, Yugum, Red bean paste, Tea bag, Coffee bag, Powder, Granule, Melon seeds, Beans, Candy, Detergents, Mask, etc.

Double Toggle Injection Molding Machine (SMV Series)

Categories : Horizontal Injection Molding Machines

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Multi steps injection pressure and speedcontrol. • Steel bushes have a hardness of HV800 for wear resistances. • Auto-lubrication system is provided to assure the constant lubrication of the toggle mechanism • Multi-stroke hydraulic ejector ensures positive ejection of the product and enables unmanned production with or without the use of a robotic arm. • Differential hydraulic circuit shortens cycle time and saves energy. • Low pressure mold protection system was used to avoid mold damage or excessive wear.