AT - 12, 18

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C Humidity Range: 40~80% Cooling Capacity: 2.8~5.2 KW

JH Series-Single Station

Categories : Automatic Blow Molding Machines

●Supply All Electric type and Hybrid type Blow Molding Machine. ●Much lower noise. ●Reduced the cost of maintenance and time. ●High stable quality of production. ●Save more then 72% energy. (to run 24 hours)

Heat Transfer Film for ABS Materials

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. All kinds of ABS plastic products can use heat transfer, as long as the surface is smooth and flat, the design and product can be perfectly combined. Heat transfer film has many function which direct printing doesn’t have. Using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

PET Stretch Blow Molding Machine - TEM12S2

Categories : Automatic Blow Molding Machines

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating Low-pressure air compressor will NOT be required due to high-pressure recovery system. High efficient air recovery system up to 45%

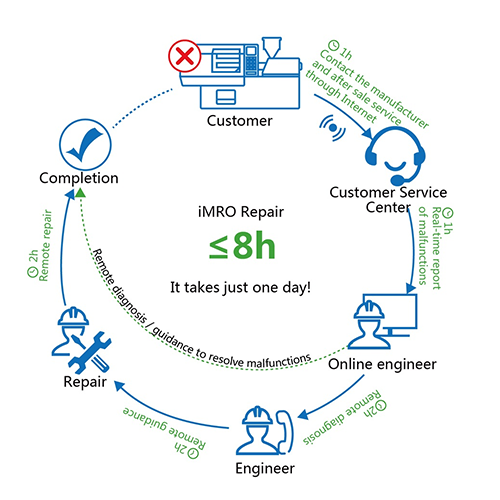

Intelligent Maintenance System

Categories : Industrial Software

A set of maintenance, service in one of the software which..

Iron Powder Type Machine

Categories : Vertical Injection Molding Machines

Clamping pressure is stable and production efficiency is high.

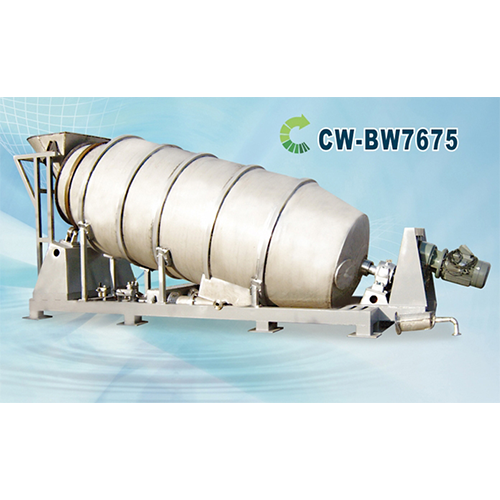

PET Bottle pre-washer BW-7675

Categories : Plastic Washing Line

No need of De-baler because you can feed 2~3 baled PET bottles at same time without tear them apart. The period of time for washing is 45 min. After years of experiences and improvement, this unit can wash the bottles by HOT water and Chemicals, and has good performance on de-label function especially when you have labels which is glued on the bodies, and which is not easy to get rid of by scratching. Performance of labels removed is able to achieved 98% if integrate following label separation system.

HX Series 30-200 Ton

Categories : Industrial Robots

Plate Automatic Jointing Machine PTR-500

Categories : Extrusion Lamination Machines

Patented Automatic Receiving Mechanism: Performs the material jointing work automatically. Automatic Charging Mechanism: The vacuum robot is used to move the material to the designed position automatically. Servo Transmission Control: Uses 3-axle servomotor to perform high-speed transmission and positioning. Versatile Dimension Flexibility: The parameter fine-tuning can be performed according to the characteristics of different materials. Automatic Feeding Mechanism: Delivers the jointed material automatically. Parameter Storing System: Performs module-based memory for the production figures to facilitate the parameter management.

Circular Loom (Heavy Duty Fabrics)

Categories : Industrial Knitting Machines

Consistency with simplicity and flexibility, the looms are easy to operate and maintain, while producing high quality heavy duty fabrics suitable for FIBCs, Tarpaulins and other special textiles.

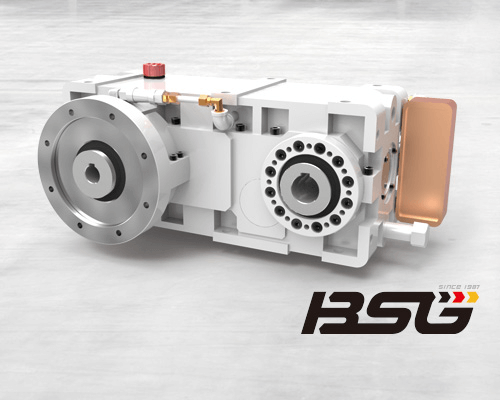

Direct Drive Gearbox

Categories : Gears

Silicone Double Injection Machine - YD Series

Categories : Silicone Injection Molding Machines

Silicone and plastic double injection system Satisfy two requirements in once.

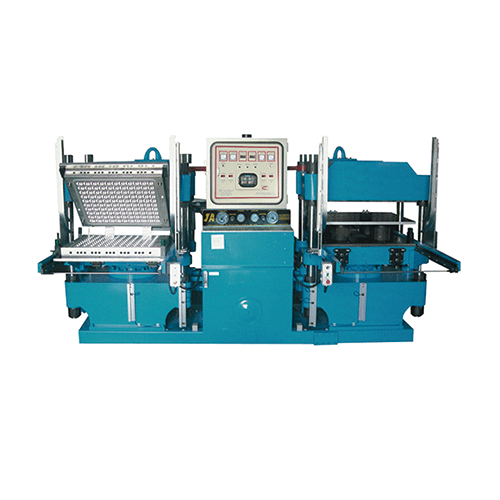

Rubber Back-Injection Molding Machine

Categories : Rubber Injection Molding Machines

Rubber Back-Injection Molding Machine Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

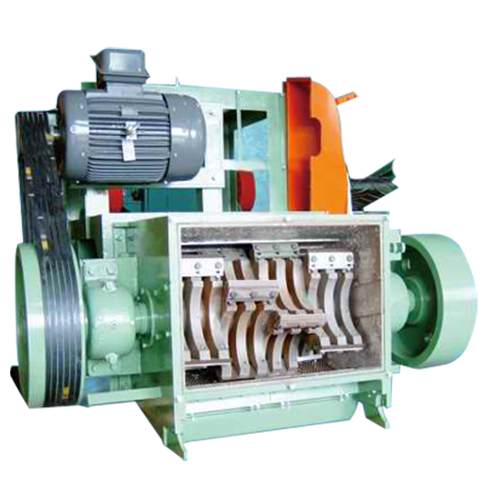

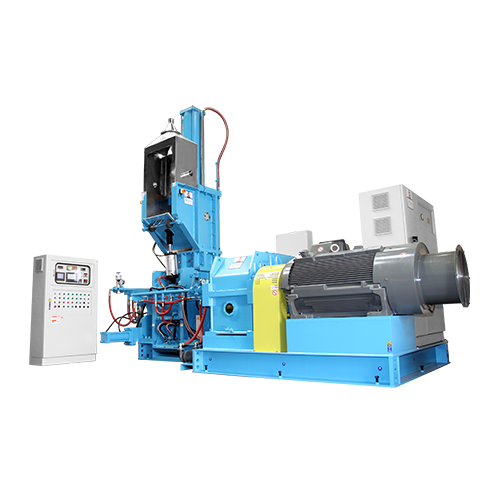

Air / Hydraulic - Intensive Mixer (BANBURY)

Categories : Rubber Mixers

Improve Compound Shearing Force And Superior Dispersion For Curing Process Low Temperature Mixing

P-14

Categories : Injection Molds

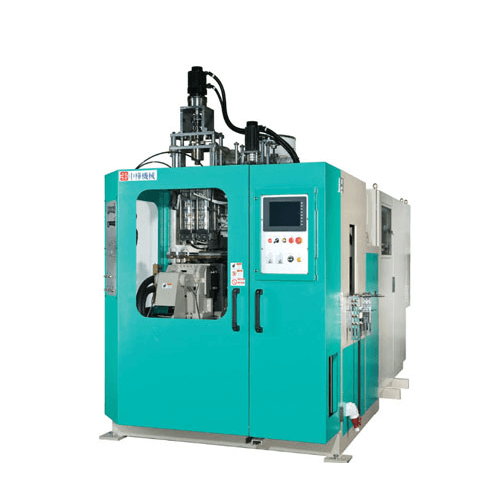

Automatic-Blow-Molding-machine-L Series

Categories : Automatic Blow Molding Machines

Full Shine's L Series Blow Molding Machines are suitable for producing big and large containers, such as water tanks, chemical drums, jerry cans, and automobile components. These machines are equipped with accumulator-type mold heads and multi-point parison controllers. Mold carriages are perpendicular and easy for producing different-shaped products.

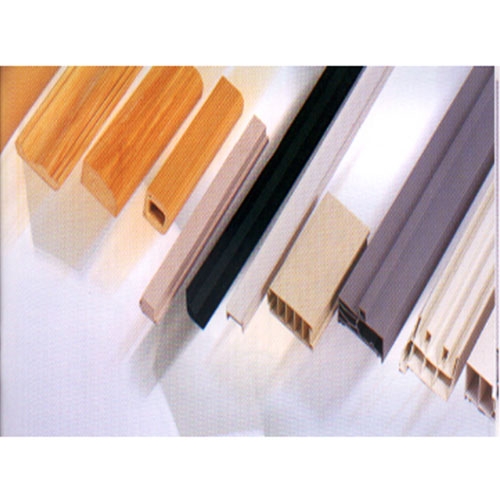

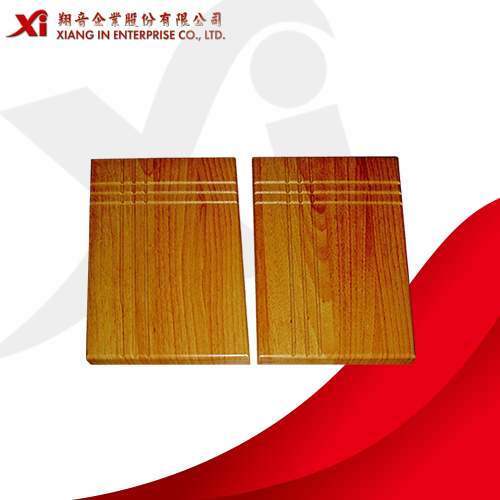

Heat Transfer Film for Wood Materials

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. With our high quality ink and printing advice, printing on wood prodution can't not be more than easy. Heat transfer film or thermal film will be perfect solution for PP printingTransfer printed film has many function which direct printing doesn’t have. Using transfer printed film and transfer printed machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

WT - 60, 90

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 14~26 KW

Toggle Injection Molding Machine SW-90B to SW-570B

Categories : Horizontal Injection Molding Machines

STANDARD EQUIPMENT & ACCESSORY FOR SW-B SERIES ● Hydraulic device and electrical control for core puller and unscrewing ● Automatic mold height adjustment ● Automatic oil lubricator ● Air ejector device ● Micro mold adjustment device ● Anti-vibration damper ● Mold clamps

PA6 (Electrical grade)

Categories : PA(Polyamide) /Nylon

Provide static dissipative and electrostatic discharge protection requirements.

UTS 650-1100

Categories : Industrial Robots

Document management system installed for effective management of arm tooling Free encoding functions / 3D display showing parameters for the programmed stacking motion User-friendly encoding Built-in PLC software (LADDER diagram) An easy-to-use teach pendant

S-08

Categories : Injection Molds

High Filler Modified Compound Making Line (CaCo3, TiO2 or Talc)

Categories : Compounding Lines

High Filler Modified Compound Making Line (CaCo3, TiO2 or Talc) Our High Filler Modified Compound Making Line uses our extruder machinery to process different types of compound materials into pellets. Our simple to operate line, comprises of a dispersion kneader and extruder to meet all of your specific compound making needs. (HDPE, Recycled HDPE, Ti02, Talc, PP+CaCo3 etc) We can also provide automated production line for you, and to adjust and customize equipment according to your needs.

Sphere Rubber/Silicone Compression Molding Machine

Categories : Compression Molding Machines

Equip with patent rail mold-open, very fast and easy to operate. The complete set includes both molds and molding machine. Big working bench, plenty cavities, high yield. Nature rubber Rubber of metal bonded parts Oil-resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

Post Cooling Unit for Paddle Wheel Aerator Float

Categories : Cooling Equipment / Industrial Chillers

Our Customized Post Cooling unit helps to complete the formation of the Paddle Wheel Floats because: - It reduces the total cycle time of the floats. - Increases the production output for our customers. - Strengthens the float structure. - Helps to avoid the float to deform easily.

HIGH-SPEED STEEL MOLD CUTTER HSP-12

Categories : Foaming Machinery

Innovative Feed Mechanism: In which, the auto up/down feed system is designed for the height of the molded material. Superb And Stabilized Dead-Point Accuracy: For which the dual-axle synchronized mechanical structure is designed to achieve higher lower dead point stability. High-Precision Depth Adjusting Mechanism: Which uses left/right synchronized fine-tune unit to achieve 0.01mm of fine-tuning accuracy. Parameter Saving Function: To name and store relevant parameters after being set. Molding Machine On-Line Function: To carry out synchronized control with other molding machine through on-line operation. Automatic Lubrication Mechanism: In which, the automatic lubrication mechanism is designed to reduce the daily maintenance work.

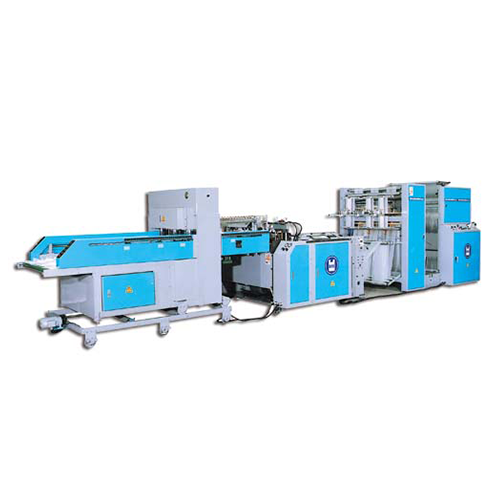

Automatic High Speed Hot Slitting T-Shirt Bag Making Machine-HEP-G3-150-Series

Categories : Plastic Bag Making Machines

● Special designed for huge production of non-tension sealed, printed T-shirt bags making. ● Programmable Logic Controllers are installed for easy operation and maintenance.

Custom-Made Machine

Categories : Compression Molding Machines

Features LIN-CHENG owns very outstanding R&D ability. In order to match your production, we can design various machines that suitable for your requirements.

PP Woven Bag Printing Line - JLRPM-SERIES

Helical toothed gear drive from main motor to each printing station Automatic hydraulic plate drum throw off during printing stop High speed printing with high printing quality

FLOOR MODEL VACUUM MAP-VG-70

Categories : Sealing Machines

1. Cutting attachment (trims seal edge up to 2mm). 2. Easy-to-move lockable trolley design.

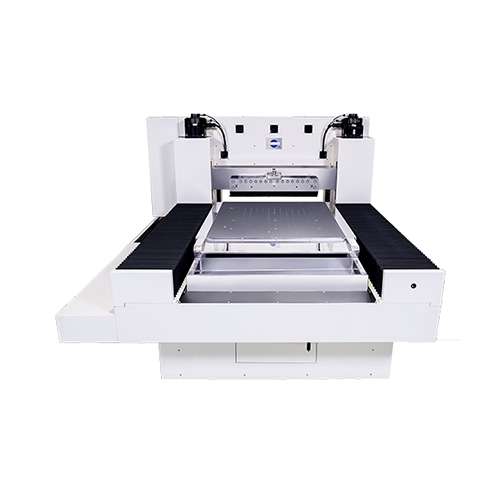

HIGH-ACCURACY ROLL-TO-ROLL AUTO FEED CUTTING MACHINE TRC-350CP

Categories : Foaming Machinery

Special Feed Mechanism: Designed for the material having different characteristics to achieve automatic machining for the soft materials. Well-Designed And Stabilized Bottom Dead-Point Accuracy: Using patented bottom dead-point mechanism exclusively developed by CHULIING to achieve +/-0.005mm of repeated positioning accuracy. High-Accuracy/High-Depth Adjusting Mechanism: Used high-accuracy mechanism to achieve fine-tune accuracy for up to 0.01mm (0.001mm is for optional). High-Efficiency Boosting Circuit: Which reduces over 30% of power consumption as compared to conventional circuit. Multi-Layer Material Flexibility: To handle over 4 rolls of materials during one machining process to achieve doubled growth of production efficiency. Unique Tension Transmission Mechanism: To effectively control the deviation tolerance during material conveying as to alleviate the production yield rate. Automatic Lubrication Mechanism: The machine uses automatic lubrication mechanism to easing the burden of daily maintenance. Waste Recovering Mechanism: After cutting, the machine will recover the waste automatically to save space while enhancing the operability.

P-16

Categories : Injection Molds

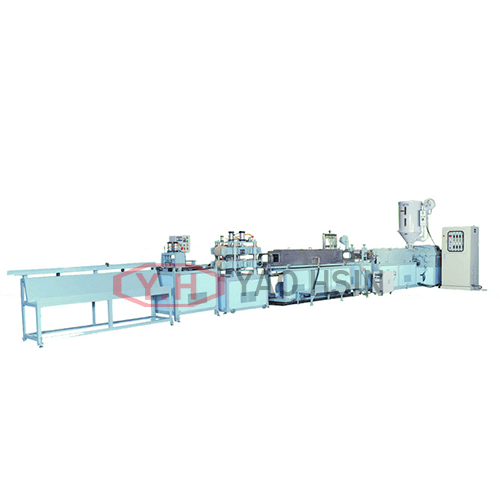

EXTRUDER FOR PVC/TPO SOFT FILM

Fruitive International Co. helps consult and design different types of PVC / TPO soft products extrusion line for customers and suitable for a variety of PVC / TPO soft products production. It is applied to products such as PVC tablecloth, shower curtain, tiles backing, transparent film car decorative, flloring, TPO tablecloth, printed film and so on. The extruder and calender unit that consists of rollers is also the core equipment of a production line. Hence, this is important when choosing the right products. We always make every effort to assist our clients to select the requested products in regarding to some technical aspects such as length and diameter ratio of the extruder, the width and the material of the calendar roller with the maximum capacity in order to meet the aimed production capacity and product demands. We achieve making the best thickness contribution by adopting the technology of moving rollers, roll bending, and other means. It is also an option to equip the most up-to-date full automatic control as well as the thickness monitor on our calenders.

Coating Equipment Sheet To Sheet Coater

Categories : Inspecting and Testing Equipment

Slit Die coating on sheet substrate to check the coating thickness and uniformity. SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid

Bait Making Machine - YH Series

Categories : Silicone Injection Molding Machines

Use plunger-type material less barrel, material is silicone.