High Speed Mono Extrusion Coating & Laminating Machine (WEL-H Series)

Categories : Extrusion Coating Machines

In order to save the wastage of web path & minimized the film threading time. The machine adopt leading brands T-Die to ensure the stable performance & constant high quality coating gauge, The screw and barrel has strict designed & treated to achieve well mixed of resin. Whole machine automation and tension with PLC control and all un/rewinders with nonstop turret auto splicing.The operation of the machine is very simple and user-friendly. The high speed version of mono extrusion coating & lamination machine adopted more advance equipment, such as auto air gap adjustment unit and auto water temperature control device. Those extra function allow to saving many operation procedure during the production. Thus the operator can be more concentrated on major operation and enhance the finished product quality.This type of machine is suitable for more high productivity demand.

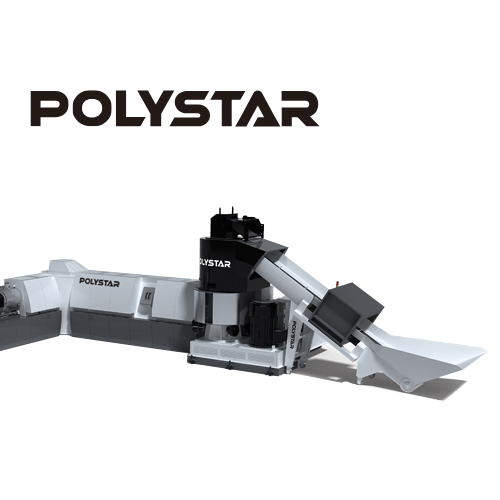

Two Stage Recycling Machine: Repro-FlexPlus

Categories : Plastic Waste Recycling Machines

Two Stage Recycling Machine with integrated cutter compactor. Improved degassing and filtration.

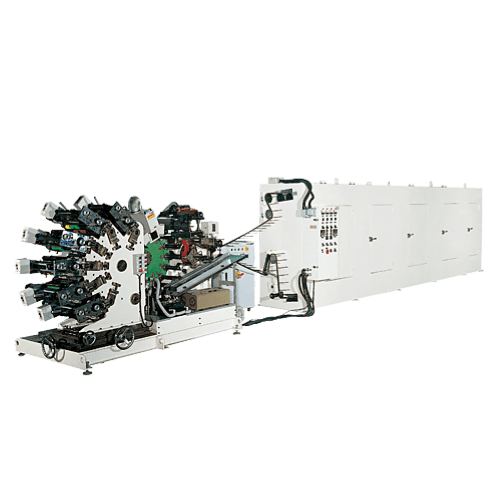

6 Color PE Tube Dry Offset Printing Coating Machine PCD-80-06-RE

Categories : Hot Stamping Machines

Precise index ensures accuracy of every movement. It is easy to disassemble the printing mandrel. Tube feeding system works with detector. Coating mechanism will not move. Without tubes on mandrels. Equipped with precipitator. Corona system can keep tube clean before printing. With optional sleeve printing mechanism. Tubes are headed directly after printing. No double-heading or double cutting procedures and save material. Vastly used on printing different shape of tubes.

Continuous Extrusion Blow Molding Machine with Visi-Strip function

Categories : Electric Blow Molding Machines

This series is excellent for producing containers such as engine oil bottles, machine oil bottles, gasoline bottles, and similar containers. A small screw can be specially installed to indicate the color of the bottle leveling line.

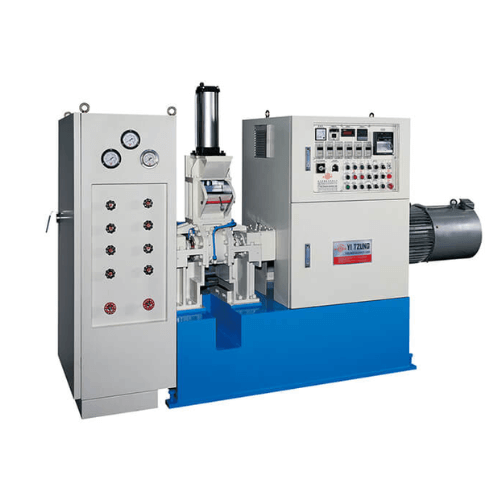

Laboratory Intensive Mixer

Categories : Dispersion Kneaders

The 1.8L Laboratory Intensive Mixer is designed for material research and develpment applications in the laboratory. The heating chamber (mixing chamber) and rotorsave built with water circulation sleeves assuring excellent cooling affect and heat transfer efficiency.

Force Side Feeding Plastic Recycling Machine (RECO Series)

Categories : Plastic Pelletizer Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. More Labor-saving The feeding control system monitors the ampere and controls the feeding speed automatically. Only 1~2 operators are required for an entire plant. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Force Side Feeding Plastic Recycling Machine (RECOi Series)

Categories : Plastic Waste Recycling Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Cutter Compactor Plastic Recycling Machine (KRIEGER Series)

Categories : Plastic Crushers

Compacting & feeding The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Bag Making Machine for Flower Sleeves

Categories : Bag Making Machine by Applications

Servo motor - Accuracy and highspeed @180 bags Malfunction alarm / stop - Abnormal temperature / No material feed / Photocell track miss / Bag jam

40TB Temperature And Pressure Double Indicator / Alarm Unit

Categories : Indicators and Sensors

Inputs configurable from faceplate. Easy strain-gauge calibration with sensitivity auto-ranging. Control of sensor power supply (input 1). Selectable code protection. Possibility to configure the unit. Power supply for transmitters. Easy to configure . Custom linearization available. Engineering units of the most common physical quantities available either on display or on labels. Acquisition and alarm programmable from 15 up to 120 msec. with resolution from 16000 to 4000 divisions Retransmission of variable values 3 alarms completely configurable from faceplate. 4-wire, configurable serial line. Protocol: GEFRAN CENCAL or MODBUS

2400 Fast Display / Alarm Unit

Categories : Indicators and Sensors

Double configurable input for strain gauge / potentiometer / linear signal / TC / RTD Two auxiliary analog inputs Differential measurement High precision: 0.1 % f.s. ±1 digit High tripping speed Automatic calibration for 6-wire strain gauge Transmitter power supply and strain gauge probe power supply Memory: min. peak, max. peak, max. peak – min. peak 3 configurable alarms, failsafe function 2 digital inputs Up to 4 relay/logic outputs 5-digit display Serial communication interface: - RS485 MODBUS RTU protocol (optional) - Profibus DP slave (optional) Isolated analog retransmission output (optional)