Electronic Flow Control Valve 0-2100L/min

Categories : Separators

FC series for regulating the flow volume of liquids and gases. The position of the precision throttle, which is connected directly to a linear motor, determines the flow rate. This valve is used in the food industries, gas blending, water mixing, vacuum control...etc The control electronics allow the setting of the motor via an analog or digital signal, whereby the flow rate can be adjusted almost continuously. A set position can also be maintained unpowered due to the stepper motor technology.

MN Series Melt Pressure Transducers - Voltage Output

Categories : Indicators and Sensors

The MN series of Gefran, are pressure transducers for using in High temperature environment. The main characteristic of this series is the capability to read temperature of the media up to 400°C. The constructive principle is based on the hydraulic transmission of the pressure. The fluid-filled system assures the temperature stability. The physical measure is transformed in a electrical mea-sure by means the strain-gauge technology.

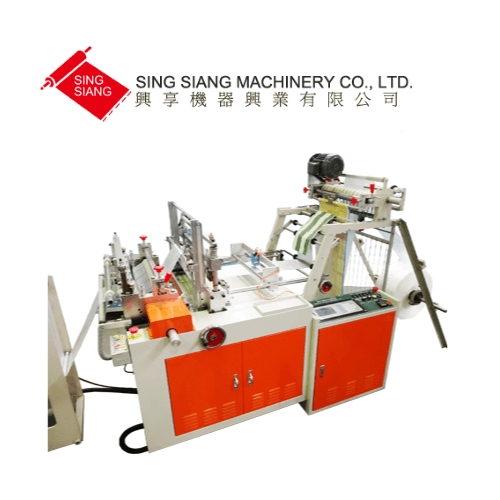

Servo Motor Driven Perforating Bag Making Machine with Automatic Rewinding Module - Three Fold

Categories : Bag Making Machine by Applications

1. Servo Motor Driven, Efficient mechanical structure From film to final bag, one process flow. 2. Unique designed Multi-Functional Folding Device can fold three types of bags. 3. Adjustable Multi-Functional Folding Device can fold any size of bag without changing the rack. 4. This can produce Coreless Rolls. 5. User-friendly Control Panel, easy to understand easy to operate. 6. Digital control for production length adjusting, precise and less wastage. 7. Simple design, assemble precisely, durable, and easy for maintaining. 8. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 9. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 10. High production efficiency to save labor and time.

Seaming Machines SEAM-350D-COMPACT (K4)

Categories : Shrink Sleeve Machinery

-for Shrink sleeve. -Increase production. -Non stop Turret. Features -Increase production. -Decrease inspection time. -Reduce waste. -Decrease labor.

Automation Equipment - Vertical Transporter

Categories : Industrial Robots

The mechanical arm signals are connected to accurately catch the finished product and protect the finished product. After tilting, the angle is automatically tilted to slide the finished product toward the workbench. RRP plastic countertop, does not scratch the finished product, beautiful appearance and wear resistance.

Bag on Roll Machine With Automatic Rewinding Module and Auto Labeling

Categories : Bag Making Machine by Applications

1. Servo Motor Driven, Efficient mechanical structure From film to final bag, one process flow. 2. Unique designed Multi-Functional Folding Device can fold three types of bags. 3. Adjustable Multi-Functional Folding Device can fold any size of bag without changing the rack. 4. This can produce Coreless Rolls. 5. User-friendly Control Panel, easy to understand easy to operate. 6. Digital control for production length adjusting, precise and less wastage. 7. Simple design, assemble precisely, durable, and easy for maintaining. 8. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 9. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 10. High production efficiency to save labor and time.

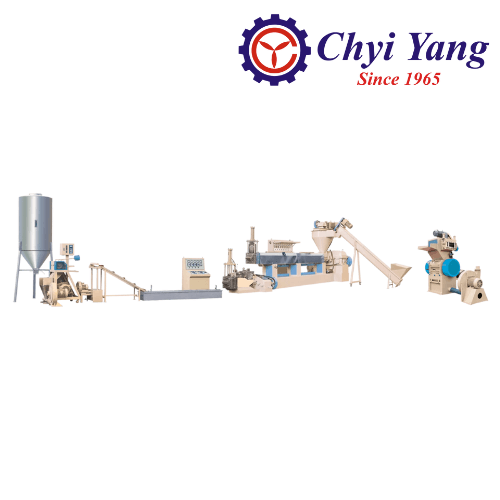

Force Feeding Single Stage Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing, Suitable for a variety of raw materials, Easy to operate; prority transcends traditional model, Spaghetti cutting is suitable for high melting index plastic, Optional equipment- crusher and mixer, enables every batch of material to mix well, No noise during pellet cutting

Servo Motor Driven Filter Bag Making Machine

Categories : Bag Making Machine by Applications

1. Servo Motor Driven, Efficient mechanical structure produce 120 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Equip with Front Thick Bags Sealing Device, will able to produce any long length of bags. 8. SHCG-T Twin Servo Motor Driven Model can produce two different size of printed plastic bag at same time. • The Conventional mechanical clutch / brake and rack & pinion system is also available.

Dry Laminating Machine Shafted Type DL-1000/1300

Categories : Industrial Lamination

This machine is for the Laminating process that uses a solvent-based adhesive. Reliable tension control with a mature lamination process able to make high-end products such as retort, sterilize and medical pouches. The gravure coating station allows high precision and consistency in coating weight. An efficient drying tunnel has high performance in vaporizing solvent completely to keep the product safe. Various options of heating solutions for drying tunnels are available. The energy-saving system is an option to help decrease carbon footprint and the cost of production

Servo Motor Driven Double Layer Bag Making Machine

Categories : Plastic Bag Making Machines

1. Servo Motor Driven, Efficient mechanical structure produce 120 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Optional accessories: hot pin conveyor stack for T-Shirt bag making machine.

WASTE PLASTIC RECLAMATION & PELLET REGENERATING MACHINE (SPAGHETTI TYPE)

Categories : Plastic Pelletizer Machines

Available for dry and wet material, but you need to advise us in advance Simple operation & high capacity Application for PP, HDPE, LDPE, LLDPE, PS etc. Double extruder is used for better degasification Forced feeding for film We didn’t show all our models, please don’t hesitate to contact us for other size of recycling machines.

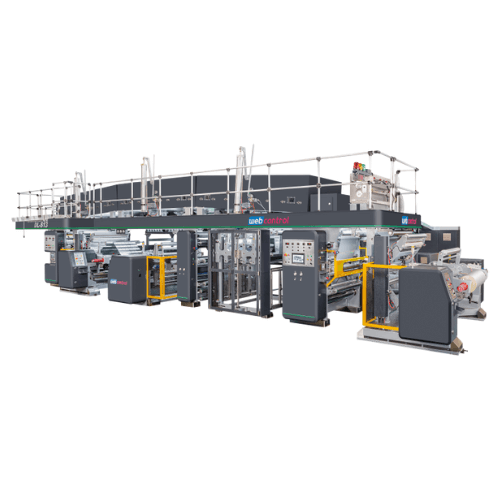

Solvent-less & Solvent-base Combi Laminating Machine(WDSL Series)

Categories : Industrial Lamination

For the solvent-free lamination, WORLDLY launches solvent-less & solvent-base combi laminating machine WDSL series. The unwinder and rewinder are adopted with a double shaft turret type with automatic splicing system, which can continue splicing without stopping the machine. This also greatly enhances the work efficiency. Moreover, the manipulation is much easier and simple with the PLC digital control system and touchable human-machine interface. Solvent-less & solvent-base combi laminating machine WDSL series is the leading popular machines for solvent-free. It has higher compound speed in order to increase productivity. And, there is no wasted costs caused by the solvent evaporation. Also, the coating thickness is very thin with 100% solid ingredient which can reduce a lot of cost. The production won't produce solvent evaporation and there is no solvent residue. It all conforms to food safety regulations. Meanwhile, there's no need for drying chamber which can save energy. The solvent-less & solvent-base combi laminating machine can be ordered from solvent-base lamination, solvent-less lamination, or solvent-base & solvent-less lamination which can accomplish three-layer lamination depends on the customer's need, and the machine itself can be shorten to save space for additional use which can make a significantly cost reduction.