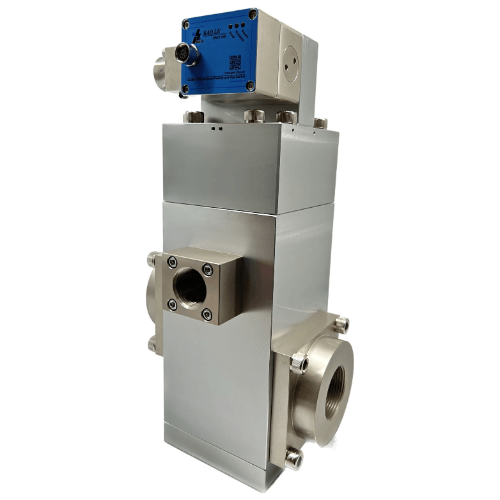

Product Serial: FC-1500+PM-1500

FC series for regulating the flow volume of liquids and gases. The position of the precision throttle, which is connected directly to a linear motor, determines the flow rate.

This valve is used in the food industries, gas blending, water mixing, vacuum control...etc

The control electronics allow the setting of the motor via an analog or digital signal, whereby the flow rate can be adjusted almost continuously. A set position can also be maintained unpowered due to the stepper motor technology.

What is an Electronic Flow Control Valve?

Electronic flow regulator and the electronic flow valve are the devices that are able to control the flow rate of fluid (liquid and gas) with an electronic signal. The digital water flow regulator is used in order to regulate the liquid flow rate while, for the gas pressure handling, electronic air flow control valve is efficiently working well usually to control the speed of cylinders and air motors. An electronic pneumatic flow control valve combining with a digital flow meter for closed loop control facilitates users with the digital reading of the liquid or gas flow rate that means the users can expect the precise quantity of flow. The digital flow control valve also offers the function of an in-built flow governing.

In various heavy manufacturing industries the electronic water flow control valve works as a power-operated device to regulate the flow of the fluid. The automatic water flow control valve lets the users get the automated digital measurement of the quantity of the liquid flow.

Ideally, the output flow rate is linearly proportional to input signal. There are different types of working principle, and in this article we will be introducing you the needle valve type driven by a stepper motor powered linear actuator. We will firstly introduce you what type of pneumatic flow control valves we offer, followed by the working principle and with what is the main advantage of KaoLu’s electronic flow control valves, and then conclude with what you should think about before purchasing an electric flow control valves.

What type of Electronic Flow Control Valve does KaoLu offer?

KaoLu offers 4 types of flow control valves. One advantage is that it can control both gas and liquid. Please click on the photo link below for further information

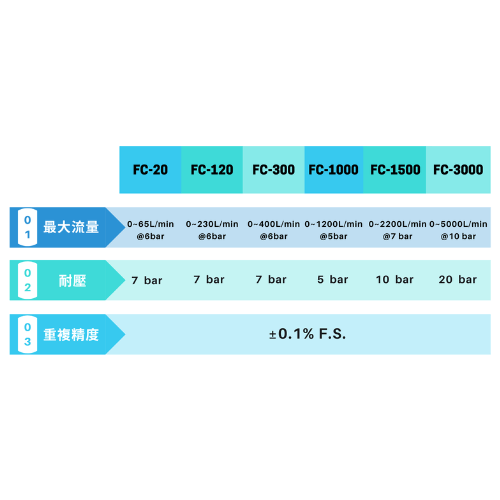

- FC20: Flow rate 65 L/min N2 gas @ 6 bar OR 1.3 L/min water @ 6 bar

- FC120: Flow rate 240 L/min N2 gas @ 6bar OR 5 L/min water @ 6 bar

- FC300: Flow rate 500 L/min N2 gas @ 6bar OR 10 L/min water @ 6 bar

- FC1000:Flow rate 560 L/min N2 gas @ 4bar OR 15 L/min water @ 5 bar

- FC1500: Flow rate 2900 L/min N2 gas @ 9bar OR 50 L/min water @ 9 bar

All four types come with an equivalent control driver to power up and control. The digital flow controller accepts either analog (0-10V or 4-20mA) or digital RS485 modbus signals. We also provide an option for an encoder that ensures that the stepper motor reaches the target position. There is also an option for a customized solution such as having a stainless steel body and wet material or 0-10V corresponds to 0-200 L/min of gas. As our business partners, we even offer the option to calibrate the torque and speed of the moving needle and control range. There is great flexibility of what our customers could achieve with our electronic flow control valve, which helps customers to solve difficult and unique issues.

Please refer to our youtube channel for some of the interesting applications:

https://www.youtube.com/channel/UCjQ9bjuSOT_csnVA9if4_EQ

What is working principle of an Electronic Flow Control Valve?

There are different types of electronic flow controller. Here we will be explaining the type that utilizes a linear stepper motor actuator and proportional needle valve.

Firstly, what is a stepper motor?

Stepper motors are brushless DC motors that rotate in steps set by a driver. The steps are determined by step angle and lead screw and controlling electronics. The driver provides electric current through electromagnets that are arranged in a ring as part of the stator assembly (the stationary portion of the motor). Due to the mechanical design of the stepper motor, the mechanical and electrical delays are minimized, which is often a problem with other types of motors. With a stepper motor, the moving accuracy, resolution, and responsiveness is a greatadvantage over others. Stepper motor has been widely used in automation, motion system, and 3D printers.

Next, what is a stepper motor linear actuator?

A stepper motor can have a threaded shaft attached to its rotating core which can then be used to push or pull a nut (needle valve) placed upon it, moving it axially. The pitch of the thread controls the resolution of the flow control valve is, this is also dictated by the step angle of the used stepper motor (full, half, quarter, etc.). Like most linear motion systems, a stepper linear actuator is sensitive to the backlash, which is defined as the maximum distance or angle through which any part mechanical part may be moved in one direction without applying resistive force or motion to the next part. Having clearance between threads results in a dead zone when the direction of travel is changed. When reversing direction, there will be no movement in the linear actuator until the clearance between threads is removed (the threads make contact again). For this reason, it is recommended that the threads have as tight a tolerance as possible. Mechanical design of stepper motor driven actuation system is imperative to the performance of the valve.

Next, what is a stepper motor driven electronic flow control valve?

Here a stepper motor is used to control the distance between the needle and valve seat. The performance parameters of flow regulating valve, such as resolution, accuracy, and repeatability are determined by how well the position of the needles is adjusted. Other parameters such as velocity, torque, the operating pressure are mainly determined by the characteristics of the stepper motor.

So, what is the advantage of KaoLu’s electronic flow control valve?

Our parameters tell the entire story. With FC series electronic flow control, we are able to withstand 7 bar of perpendicular operating pressure, with a resolution as high as 20 mL/min of air, repeatability of 0.1% F.S, and 0.1% of linearity. This is due to the motor we used, and the low flow valve to extremely low tolerance of mechanical parts, the fine thread needle we used which is extremely difficult to reproduce by others, and the control system we designed.

What should you consider when purchasing an electronic flow control valve?

You should consider 3 main factors ( we called CPR)

- Compatibility: Medium, flow range, compatibility with the valve material, and operating pressure

- Performance: Resolution, starting flow point, and linearity

- Control system

It is important to understand whether the media you used falls into the flow range of the operating valve. As each media has a different density so the flow range would be different from the nominal flow range. Next is whether the media used is compatible with the wet material and whether you would also need the body to be special material. The operating pressure is another caveat, where if you simply need flow control, sometimes it would not be a very important factor.

Next is the performance, with some applications that need fine control and adjustment between steps, such as laser cutting, the resolution dictated by the control logic and motor performance play an important role here. Furthermore, as the motion system requires to overcome initial inertia, the start flow point is should be considered.

Then comes the control system where you should check what type of control system do suppliers offer? Here we provide an external driver that has a cable connected to the control valve. The great advantage that we offer is that should you want to operate the valve from distant away from the site, we offer RS485 modbus where you could control the valve up to half a mile away from the valve.

We hope you have enjoyed reading the article, understand about stepper motor driver electronic flow control valve, understand about our products, and finally help you with selecting the right valve.

Please remember to visit our product page (even if it is not the right product for you :)

Product Serial: FC-3000+PM-3000

- less dead space

- materials and constructional design especially optimised for food applications

- low hysteresis

- simple control

- easy connection using ELSA plug-in connector