Electronic Flow Control Valve 0-2100L/min

Categories : Separators

FC series for regulating the flow volume of liquids and gases. The position of the precision throttle, which is connected directly to a linear motor, determines the flow rate. This valve is used in the food industries, gas blending, water mixing, vacuum control...etc The control electronics allow the setting of the motor via an analog or digital signal, whereby the flow rate can be adjusted almost continuously. A set position can also be maintained unpowered due to the stepper motor technology.

Servo Motor Driven Perforating Bag Making Machine with Automatic Rewinding Module - Four Fold

Categories : Plastic Bag Making Machines

1. Servo Motor Driven, Efficient mechanical structure From film to final bag, one process flow. 2. Unique designed Multi-Functional Folding Device can fold "M" Shape bags. 3. Adjustable Multi-Functional Folding Device can folding any size of bag with out changing the rack. 4. This can produce Coreless Rolls. 5. User-friendly Control Panel, easy to understand easy to operate. 6. Digital control for production length adjusting, precise and less wastage. 7. Simple design, assemble precisely, durable, and easy for maintaining. 8. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 9. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 10. High production efficiency to save man power and time.

Instant Recycling System

Categories : Plastic Waste Recycling Machines

In the past, operators throw away the sprues or waste material in small amount or wait for collecting them in big amount to reuse. However, that may be stuck dust by static electricity become too bade to be reused for a while. That not only occupies your space but also costs your time to assort, break plastic nature and regenerate in such long process. Yann Bang “Instant recycling system” use a crusher immediately granulate the sprues, waste material or NG product into small pieces as recycled material that be mixed with virgin material by a proportional valve in right proportion. The recycling process helps you cost down material outlay without effected quality. Small size with low noise and low power consumption is great for long hour operation. A small automatic peripheral instant recycling system for you molding machine combine with four individual equipments: crusher, automatic vacuum loader, hopper dryer and proportional valve. Also can be used with a robot or belt conveyor. The main function is to mix the granulated waste directly from the injection molding machine and the virgin material with a right proportion. Benefit you with less material ware and pollution for your standard productions. 1. Auto instant recycling system can recycle, convey and dry the granulated material sequentially. 2. Less noise and less dust to keep your working area clean. 3. Compact size, light weight and easy-to move. 4. Accurate mixing proportion for good quality. 5. Instant recycling provides the high-efficient productivity and save material cost.

GRM-H Compact single phase Power Controller up to 120A

Categories : Control Equipment

The features of GRM-H Series Power Controllers ensure efficient heating management even in the case of complex electrical loads, which require special features, as in the case of infrared lamps or Silicon Carbide heating elements. Compact size from 15A to 120A Load voltage 480V, 600Vac Digital IO-Link communication Configurable control mode Zero Crossing, Burst Firing, Half Single Cycle or Phase Angle Feedback V,I,V2, I2, P, Z Soft start and current limits Logic command Vdc, Analog, PWM or IO-Link Advanced partial load break diagnostics (1/8) Slave control output (Two-phase/Three-phase) Configuration and Diagnostics via smartphone App with NFC technology Calibration and alarm reset commands via Digital Input Overview The ability to propose customized control solutions allows to rapidly satisfy the most different automation needs. For this purpose, the GRP series provides a wide range of extremely compact SSRs, with a solid basic structure but scalable as current sizes (from 15A to 120A), control type and configuration features. Control An accurate process control is the condition to achieve a constant and a high-quality production. To reach this goal it is necessary to manage in the best way the different types of industrial heaters from linear resistances to infrared lamps. For this purpose, the new series of SSR provides a series of control functionalities (ZC/ /BF/HSC/PA/Softstart) fully configurable to adapt to the various needs. Diagnostics Preventing possible anomalies allows to limit or eliminate harmful downtime and production. The GRP series includes dedicated functions such as the HB alarm for partial load breakage with accuracy of 1/8 of the total load, SCR short circuit, overtemperature and power failure. IO-Link communication Factory digitization is reaching its final frontier, the field level of the automation pyramid. In this level IO-Link is confirming itself as the most suitable communication to easily reach devices such as sensors and actuators. From this perspective, the GRP series has been developed to be integrated within this automation architecture. NFC configuration Simple and safe commissioning, maintenance and quick diagnostics are now within the capabilities of devices like SSR. All this thanks to the NFC technology, which allows to extend the user interface using normal Smartphone or Tablet as intelligent configurators. Thanks to an intuitive graphical user interface, setup or diagnostics are particularly easy.

3 IN 1 Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noise; temp. controls stability; double degassing, Suitable for a variety of raw materials, Easy to operate; prority transcends traditional model, Low labor cost, Optional equipment- crusher and mixer, enables every batch of material to mix well, Two stages filter makes material more clean

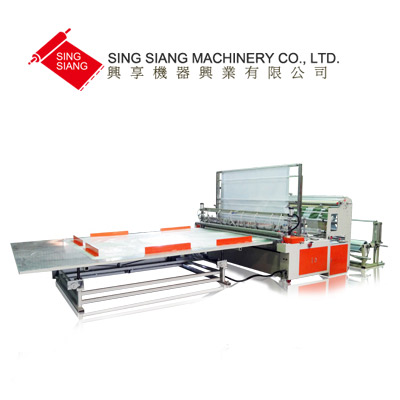

Twin Servo Motor Driven Flying Knife Bottom Sealing Bag Making Machine

Categories : Plastic Bag Making Machines

● Model:SHCG-75 ● Output Cycle/min:Max 5-30 ● Max Width:1600mm ● Max Length:3000mm 1. Twin servo motor driven, efficient mechanical structure. 2. Digital control for production length adjusting, precise and less wastage. 3. High production efficiency to save manpower and time. 4. Automatically stop when the temperature not reaching setting. 5. Automatically stop when running out of film or bag jams. 6. Flying knife device by servo motor control, unnecessary to adjust the cutting blade. 7. Using up and down heater for front sealing device, especially for heavy duty thickness up to 0.6mm. 8. With pneumatic unwind unit to lift up the film roll automatically.

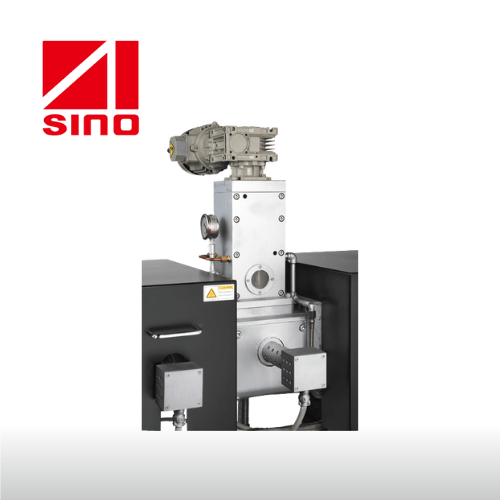

Anti-Leakage Vacuum-PSY

Categories : Valves

The PSY anti-overflow vacuum was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Developed to prevent extruded material overflow from the vacuum vent during degassing and subsequent vacuum failure. The PSY anti-overflow vacuum is driven by a pair of vertical intermeshed screws to move overflow material back to the material barrel while degassing with the vacuum. Can also be installed on side feeders to prevent overflow.

Servo Motor Driven Filter Bag Making Machine

Categories : Bag Making Machine by Applications

1. Servo Motor Driven, Efficient mechanical structure produce 120 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Equip with Front Thick Bags Sealing Device, will able to produce any long length of bags. 8. SHCG-T Twin Servo Motor Driven Model can produce two different size of printed plastic bag at same time. • The Conventional mechanical clutch / brake and rack & pinion system is also available.

M3 Series Melt Pressure Transducers-MV / V Output

Categories : Indicators and Sensors

The M3 series of Gefran, are pressure transducers for using in High temperature environment. The main characteristic of this series is the capability to read temperature of the media up to 400°C. The constructive principle is based on the hydraulic transmission of the pressure. The fluid-filled system assures the temperature stability. The physical measure is transformed in a electrical mea-sure by means the strain-gauge technology.

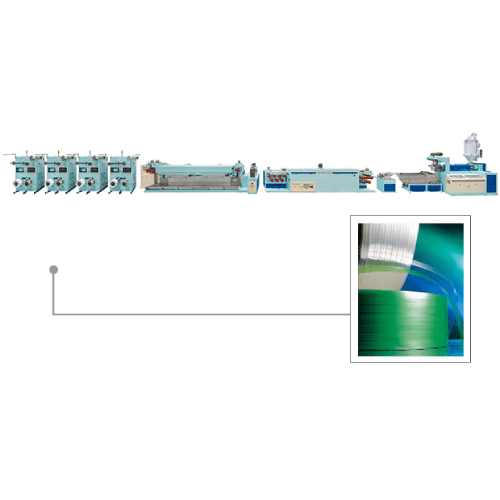

JS 237APR / JS 2310APR2 PET Heavy Duty Strapping Band Making Machine

Categories : Tape Extrusion Machines

Extruding output range: 40 - 100 kgs/hr or 80 - 220 kgs/hr. Band width: 9.5 -19mm. High precision band width +/- 0.5mm. Entire machine employs direct drive for low noise running. Gears are hardened and precision ground for quiet running performance. SACMI screw is nitrogen treated, precision ground, and stress relieved. SACMI barrel is nitrogen treated, precision ground, and stress relieved. #304 stainless steel cooling water tank. Separate adjustment for winding torque and running speed ensures uniformity of band. Stretching unit is all-gear driven with oil bath lubrication for stability, quiet running and long service life. WINDING UNIT The winding unit is driven by a DC torque motor, featuring torque adjustment. The buzzer sounds when the preset length of band is reached. Changing the gears conveniently changes the winding width. Aluminum winding rollers. Choice of 200 or 400mm core bobbin. PRE-HEAT STRETCHING UNIT The machine uses electric heating to quickly achieve high temperature. The four stretching rollers are individually driven, and heated for efficient stretching. Stretching speed is controlled by a frequency inverter for maximum stability. EMBOSSING ROLLER The embossing rollers are manufactured from SKD11 material, vacuum heat treated for superior hardness and maximum wear resistance. Embossing depth is pneumatically adjusted with indication reader for accurate reading. Separate motor drive. MAIN CONTROL PANEL The temperature for the barrel, screw, and die are separately displayed on the main control panel. Temperature can be preset. JS 2310APR2 Hydraulic screen change. JS 2310APR2 2 layer straightening operation extends heating time, ensuring the stability of bands and superior tensile strength. Hot air circulation provides for a more efficient heating solution. Equipped with a water cooling tank for upgrading cooling and stiffening performance. Outstanding dehumidifying performance ensures constant band quality. DEHUMIDIFYING DRYER The dehumidifying dryer lowers the moisture content below 0.2% to achieve the utmost performance from production materials. The dryer prevents such problems as cracking, streaking, bubbles, flow marks, poor transparency, etc., which are all caused by incompletely dry resin.

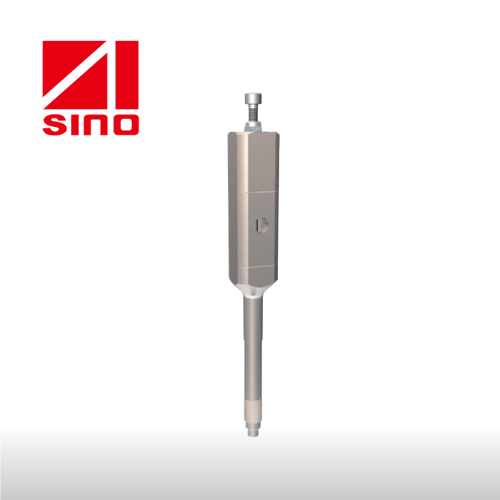

High Pressure Liquid Injector-PSX

The PSX high-pressure liquid injector was developed by Sino-Alloy Machinery as an important accessory to their extruder line. The PSX high-pressure liquid injector is made up of a storage tank, proprietary precision plunger pump, and one-way valve type fluid injector. It can generate pressures as high as 50 kg/cm. This feeder can be connected to any feeding port of the extruder. The PSX high-pressure liquid injector is also capable of injecting high pressure gases or super-fluid liquids. Not only is it suitable for the injection of liquid and gaseous additives in rubber or plastics materials, but also for may plastic and rubber reactive processes or the injection of liquid ingredients in food and pharmaceutical. The PSX high-pressure liquid injector can also be supplied with heating and insulation devices, loss-in-weight metering devices, or flow controllers for precise measurements of the input quantity.

Automation Equipment - Vertical Transporter

Categories : Industrial Robots

The mechanical arm signals are connected to accurately catch the finished product and protect the finished product. After tilting, the angle is automatically tilted to slide the finished product toward the workbench. RRP plastic countertop, does not scratch the finished product, beautiful appearance and wear resistance.