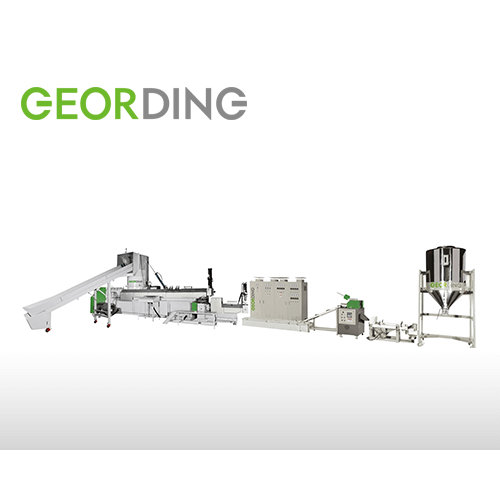

High torsion, low-noice; temp. controls stability; double degassing

- Suitable for a variety of raw materials.

- Easy to operate; prority transcends traditional model.

- Low labor cost.

- Optional equipment- crusher and mixer, enables every batch of material to mix well.

- Two stages filter makes material more clean

|

Model |

GD-85TS-3IN1 |

GD-100TS-3IN1 |

GD-120TS-3IN1 |

GD-150TS-3IN1 |

GD-175TS-3IN1 |

||||||||||||||||||

|

Shredder

Main Extruder |

|||||||||||||||||||||||

|

Screw Diameter L/D Ratio |

32 |

36 |

36 |

36 |

36 |

||||||||||||||||||

|

Main Power |

50~75HP |

125~150HP |

150~250HP |

200~400HP |

300~600HP |

||||||||||||||||||

|

Temp. Control |

7 zones |

8 zones |

9 zones |

10 zones |

11 zones |

||||||||||||||||||

|

Heating Capacity |

36KW |

40KW |

115KW |

120KW |

150KW |

||||||||||||||||||

|

Hydraulic Power |

3HP |

3HP |

3HP |

5HP |

5HP |

||||||||||||||||||

|

Max. Outpou/Hr |

100~250kg |

250~500kg |

400~800kg |

800~1500kg |

1000~1800kg |

||||||||||||||||||

|

Sub-extruder |

|||||||||||||||||||||||

|

Screw Diameter L/D Ratio |

8~10 |

8~10 |

8~10 |

8~10 |

8~10 |

||||||||||||||||||

|

Power |

20~40HP |

40~50HP |

50~100HP |

60~125HP |

100~150HP |

||||||||||||||||||

|

Temp. Control |

3 zones |

4 zones |

5 zones |

6 zones |

6 zones |

||||||||||||||||||

|

Heating Capacity |

18KW |

22KW |

25KW |

37KW |

58KW |

||||||||||||||||||

|

Cooling tunnel |

|||||||||||||||||||||||

|

Size(mm) |

3050*280*250 |

3050*280*250 |

4500*500*250 |

5000*500*250 |

5000*500*250 |

||||||||||||||||||

|

Pellet cutter |

|||||||||||||||||||||||

|

Power |

3HP |

5HP |

5HP |

7.5HP |

10HP |

||||||||||||||||||

|

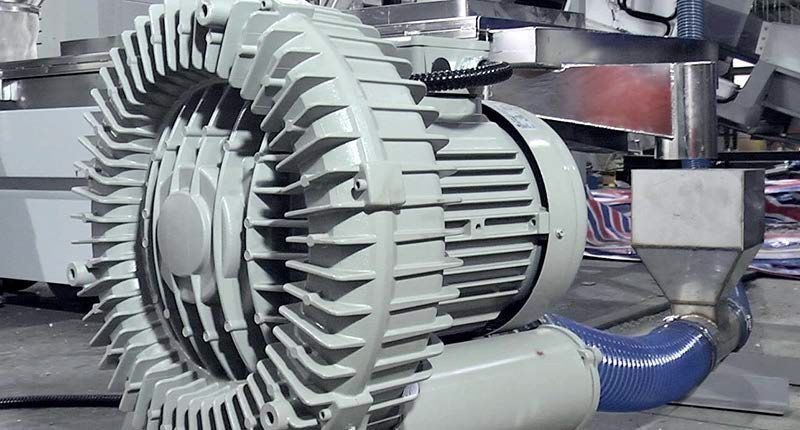

Blower |

|||||||||||||||||||||||

|

Power |

3HP |

5HP |

5HP |

7.5HP |

10HP |

||||||||||||||||||

|

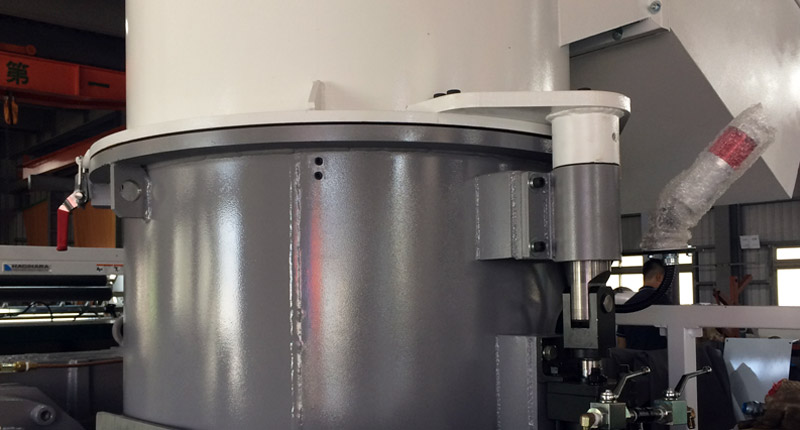

Storage Barrel |

|||||||||||||||||||||||

|

Capacity |

1000L |

1000L |

1000L |

1000L |

1000L |

||||||||||||||||||

*The product line can be made to spec meeting customer needs.

*Equipment specifications are also constanly updated. You are welcomed to contact us for details.

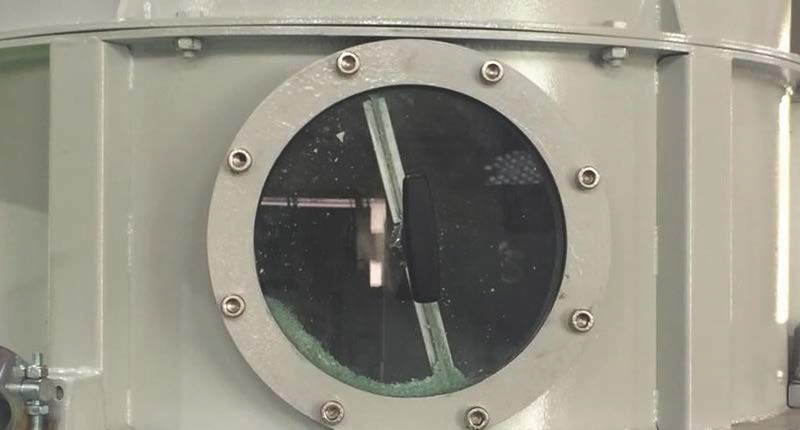

Shredder sight window with window wiper help operator to observe at anytime.

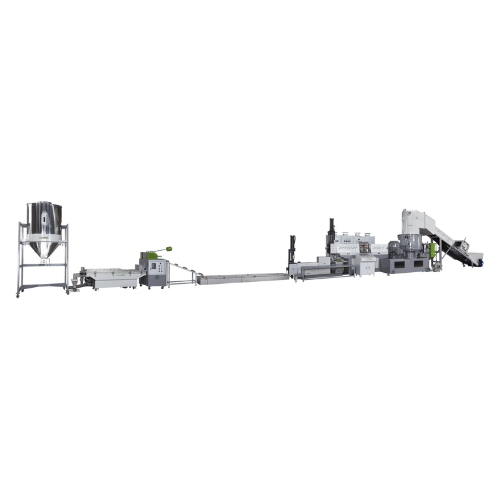

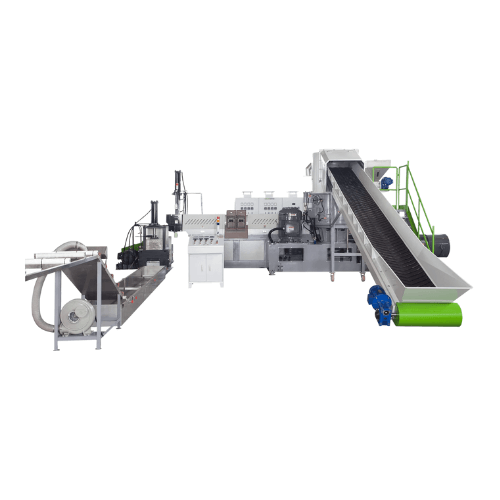

The main extruder provides the best feeding, mixing, ventilation, heating and capacity as it is designed way based on customer's raw material, capacity, and compounding degree.

Sub extruder conducts second time filtering and ventilating for dirtier materials

User-friendly spaghetti cutting system is suitable for high melting index material.

Blower with noiseless design.

Manual open device for shredder tank when it comes power cut.

PP, BOPP, OPP

PP Napkin (MI6)