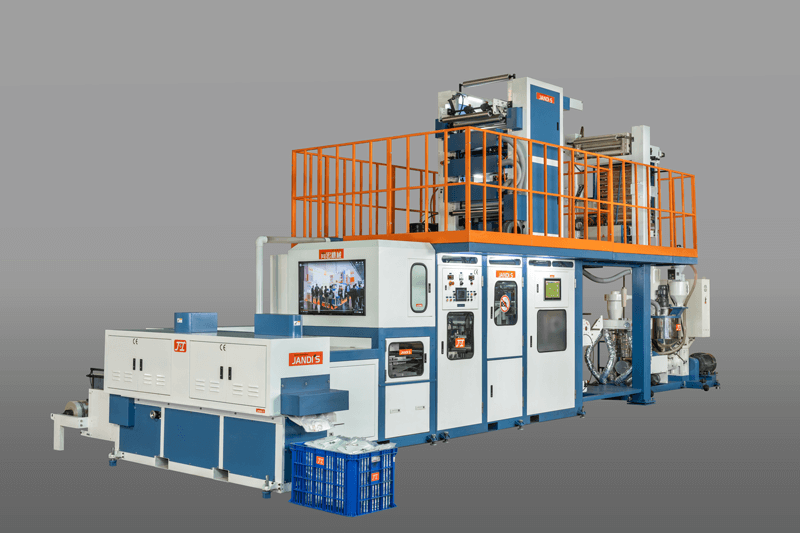

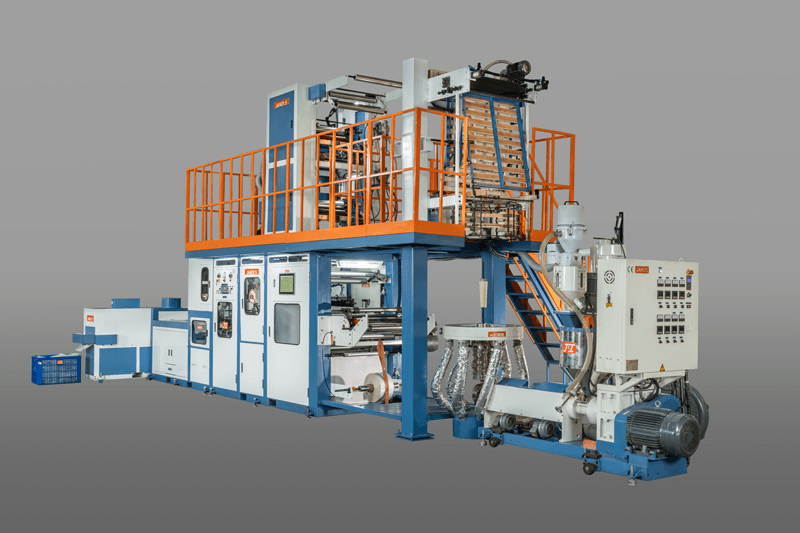

JANDI'S: JIT's Latest Machinery Development to be Showcase During K-SHOW 2022 , All-in-one Plastic Bag Production Line!

Want to be an Eco-Friendly plastic bag manufacturer? Looking for an easier way to produce T-shirt Shopping Bag and reuse the Die-Cut?

JANDI’S JIT is an innovated solution!

What are the advantages do we have here:

- Machine Advantages:

- No waste in production, die-cut reuse 100%

- Less space required for machines

- No storage space for the film rolls

- Environment-friendly water-base ink

- Required power reduced

- Co2¬ emission reduced in production

- Total lead time reduced

- Product Advantages:

- Better strength – thanks to the scraps melted earlier than resin

- Stronger Sealing – Bag sealed before the material is cooled down

- Material saving – Die-cut reused 100%, save the raw material

- Operation Advantages:

- QC right away : The finished bags are ready for inspection right after the production is started. The bag sizes, the color, the surface treatment, the printing, the sealing … QC could be made immediately, no need to wait after the long production process, which the mistake or discrepancy already happened and causing a big lost.

- Less operator required : Only 2 operators to start the machine, then only taking care of the material, ink supply and collect the finished bags.

- Production mistake reduced

- Labor cost reduced

- No need to manage and store the film rolls before printing & bag making

- No need to collect, store, sort and manage the die-cut waste

JANDI'S JIT, the best way to produce T-shirt shopping bag.

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, all in one process.

Oh! By the way, a brand new option – “Auto-Packing” is available now!

Call us for more information and see the machine running at K-2022 booth 17A06!

E-News Categories

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment