Italy FIMIC Automatic Filtration Systems, Start a New Pattern of Plastic Recycling

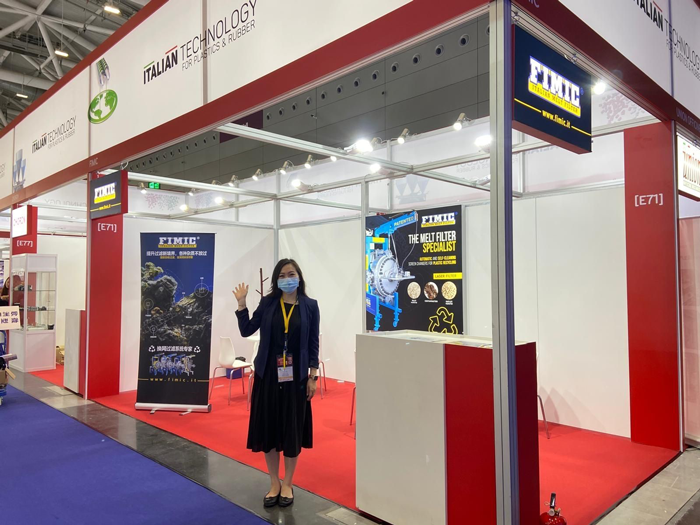

The pandemic was quickly brought under control in China, but the impact on the world is still huge. Even so, the plastic circular economy is advancing in a prolonged manner, and the plastic value industry chain needs to be adjusted, upgraded, and innovated! We have also observed that even under the strict quarantine policy, many manufacturers are willing to invest a lot of costs to come to the exhibition, like the Italian manufacturer FIMIC. They are experts in recycling filters. They not only participated in CHINAPLAS 2021 but also appeared at the Plastic Recycling and Circular Economy Forum and Exhibition on April 12.

The editor is honored to have an interview with Chen Yingpin and Ms. Aria, the business representative of FIMIC Asia.

PRM Editor: The Asian market may be relatively unfamiliar with the Italian FIMIC brand. Please introduce FIMIC to everyone first.

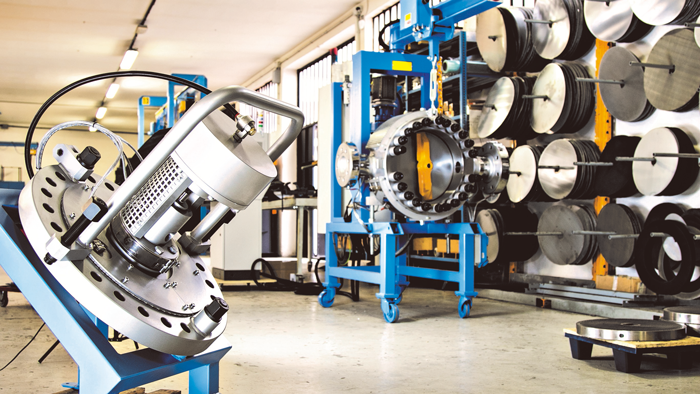

Aria: FIMIC comes from Italy, specializing in the design and manufacture of filter screen changing systems and hydraulic cutters, and has more than 50 years of experience. Its well-known RAS series automatic filter changing system has successfully installed more than 300 filter changing systems in different countries, and the number of installations continues to increase! The design concept of the FIMIC screen changer system is simple operation and maintenance, processing all kinds of impurity plastic waste, with extremely low material loss and extremely low cost of consumables. Operating cost, labor, and flexible installation on various recycling machines. In the past ten years, FIMIC's screen-changing system has been welcomed by plastic recycling companies in various countries.

PRM Editor: What is the difference between FIMIC's automatic filter screen changer and traditional manual screen changer?

Aria: The screen changing system developed and manufactured by FIMIC has an automatic screen scraping device. While filtering impurities on the screen surface, the screen surface is constantly cleaned by the screen scraping device, so that the plastic melt can always be smoothly sent to the pelletizing unit for granulation. It can handle plastic waste such as HDPE, LDPE, LLDPE, PP, PS, EPS, ABS, PVC, etc. When the traditional manual screen change is used to dispose of post-consumer plastic waste, the screen needs to be changed frequently every few minutes, which requires a lot of labor and consumes a lot of screen spare parts. FIMIC's fully automatic system can extend the time of screen change to once a week or even once a few weeks or months. Give plastic recycling companies more opportunities to deal with waste with more impurities.

PRM Editor: Can you talk about your product advantages?

Aria: FIMIC screen changer uses laser-engraved mesh surface, the finest can filter 80 microns (180 mesh), while exquisite filtration, without sacrificing overall productivity. In addition, FIMIC provides the lowest-priced spare parts on the market, allowing plastic manufacturers to significantly reduce operating costs during production. At present, FIMIC has installed more than 300 automatic networks switching equipment and has a wealth of practical experience. Serving major plastic recycling factories in the European and American markets. Since the K exhibition in Germany in 2019, FIMIC began to share the concept of the automatic screen switching systems to customers in Asia. So far, it has cooperated with several major plastic recycling factories in Asia to help customers improve recycling efficiency.

PRM Editor: Based on our observations, China is paying more and more attention to the issue of circular economy. Do you also have insight into this demand and come to participate in CHINAPLAS 2021?

Aria: This year is our first appearance at CHINAPLAS, and we also participated in the recycling forum the day before. Although the epidemic has brought travel restrictions, FIMIC still went to the exhibition site to share experience with more buyers and provide buyers with more information about recycling. The discussion of plastic recycling issues in Asia is getting louder and louder, and many recycling companies also plan to upgrade their plant equipment. Under the epidemic situation, the CHINAPLAS exhibition site is still vigorous. Through the recycling forum and this exhibition, there will be more opportunities to meet, interact, and share more plastic recycling trends from all over the world with the plastic recycling industry in Greater China.

PRM Editor: Can you talk about the impact of the pandemic on FIMIC?

Aria: Although the pandemic has caused many inconveniences, in the past year, FIMIC's installation services to customers around the world will not be interrupted due to travel restrictions. During the pandemic, FIMIC worked with customers to install remotely. As of today, more than 50 machines have been installed, and each machine is in smooth operation.

FIMIC expects that the pandemic will be brought under control as soon as possible, and will share more new plastic recycling information with more plastic recycling companies in more exhibitions in the future.

In this interview, let us know more about FIMIC. Environmental issues have become a hot topic in recent years. FIMIC's emphasis on and investment in environmental issues, even under the influence of the epidemic, FIMIC can still continue to serve global customers through remote installation. Thanks to Aria for her sharing and insights!

|

Official Website: www.fimic.it FIMIC in PRM-TAIWAN: https://www.prm-taiwan.com/com/fimic.html |

Extruders and Extrusion Lines

- Air Bubble Film Extrusion Line

- Air Bubble Film Extrusion Line

- Air Bubble Sheet Co-extrusion Line

- Bag Making Machines

- Blow Film Making Machine

- Blown Film Extruders

- Blown Film Making Machine

- Cast Film Machine

- Coating Machine

- EPS/EPE Foam Sheet Extrusion Lines

- Extruder

- Extrusion Laminating Machines

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Monofilament Extruding Machinery

- Monofilament Extrusion Line

- PET Strapping Band Extrusion Lines

- Plastic Bag Making Machines

- Plastic Film Co-Extrusion

- Plastic Pipe Making Machines

- Plastic Tube Making Machine

- PVC Hose Making Machine

- Straw Making Machines

- Twin Screw Extruder

- Twin Screw Extruders

- Woven Bag Making Machine

Plastic Recycling Machinery

- Bottle Washing Line

- Crusher

- Granulators

- Pelletizer

- Pelletizers

- Pelletizing Machines

- PET Bottle Recycling Line

- PET Hot Washing Line

- Plastic Pelletizing Machines

- Plastic Recycling Equipment for Preprocessing

- Plastic Recycling Machines

- Plastic Waste Recycling Machine

- Recycling Lines

- Recycling Machine

- Shredders

- Squeezers

- Washing Lines

- Waste Recycling Equipment