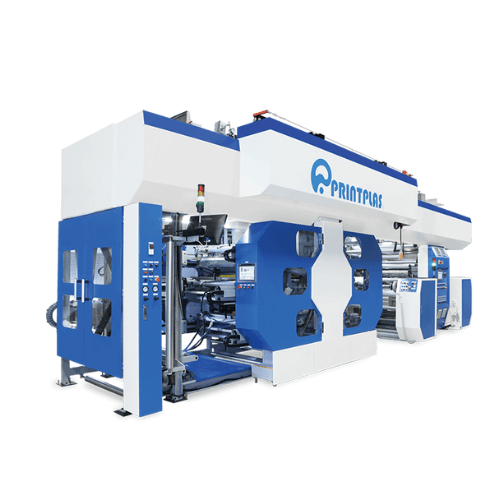

4/6 COLOR CI HIGH-SPEED FLEXOGRAPHIC PRINTING MACHINE PKF-6CI SERIES

Categories : Flexographic Printing Machines

Equipped with internet accessible control system for remote diagnoses of programming and electronic components. CI Flexoprinting Mahcine Flexographic Printing Machine FLEXOGRAPHIC PRINTING MACHINE FLEXO PRINTING MACHINE FLEXO STACK PRESS FLEXO PRINTING PRESS CI PRINTING PRESS CI PRINTING MACHINE PAPER PRINTING MACHINE PAPER PREPRINT PRINTING MACHINE OFF LINE PRINTING MACHINE

Low Pressure Proportional Regulator(0-8bar)

Categories : Indicators and Sensors

Product Serial: QKL-B1T.B2T/QKL-B3-1.B3-2/QKL-B3-1A This series is a complete closed loop servo system consisting of two solenoid valves, an internal pressuretransducer, and electronic controls. Based on analog signal, the pressure is controlled by two solenoidvalves to maintain precise pressure; one valve functions as inlet control, the other as exhaust. The pressureoutput is measured by an internal or an external feedback pressure transducer that provides a feedbacksignal to the electronic controls. The regulator is suitable for industries that require precise pressurechanges at any time and monitor pressure values. Available with 3 selections of input signal: 0-10VDC,4-20mA, or RS485 Modbus. Monitor signal can be chosen from 1-5V, 0-10V, or 4-20mA. Internal pressuretransducer comes with B1T, B3-1, and B3-1A series, whereas B2T and B3-2 uses an external pressuretransducer for feedback (ideal for when the vessel is distant away from the regulator). All our products have CE, SGS, RoHS certification with ISO13485 quality system.

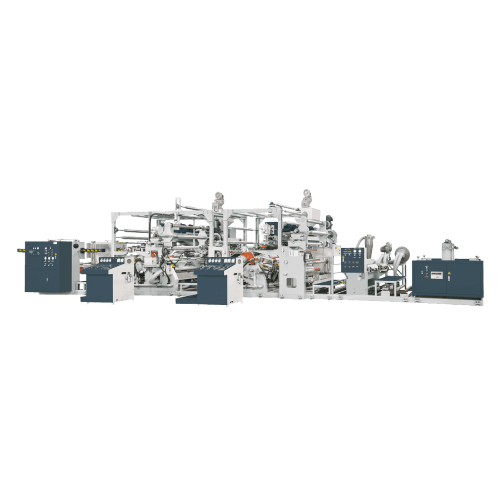

Tandem Extrusion Lamination Machine (YSL-T)

Categories : Industrial Lamination

This series of machines are available for tubular woven bag, other working materials to do double side lamination process.

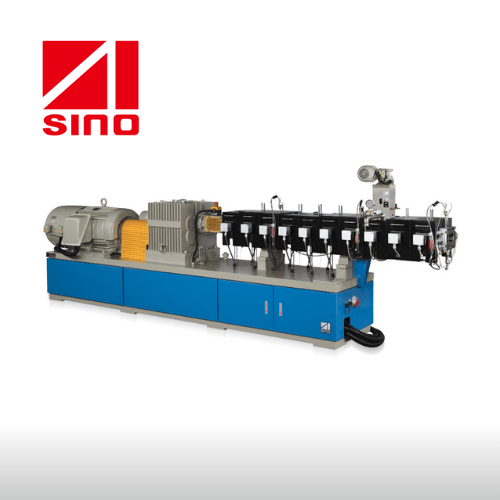

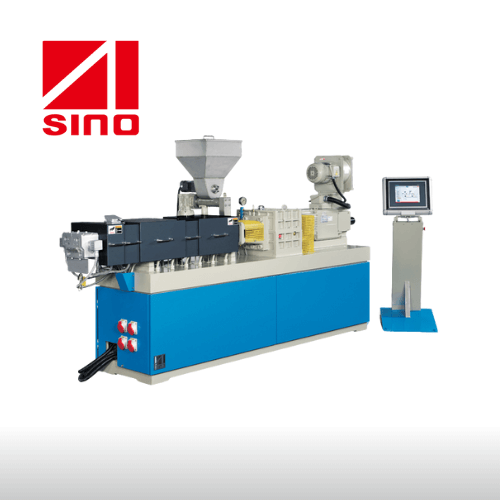

Co-Rotating Twin Screw Extruders-PSM50

Categories : Twin Screw Extruders

The optimization of the PSM50 series resulted in more efficient and durable designs. The PSM50 series has mid range production capabilities, and easy operation in reasonable price. All PSM50 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

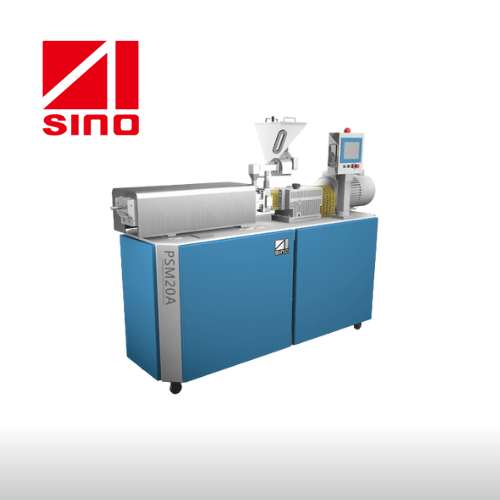

Clam-Shell Design Co-Rotating Twin Screw Extruder-PSM20A

Categories : Granulators

The PSM20A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

Compact Co-Rotating Twin Screw Extruder-PSM30A

Categories : Twin Screw Extruders

The PSM30A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM30 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

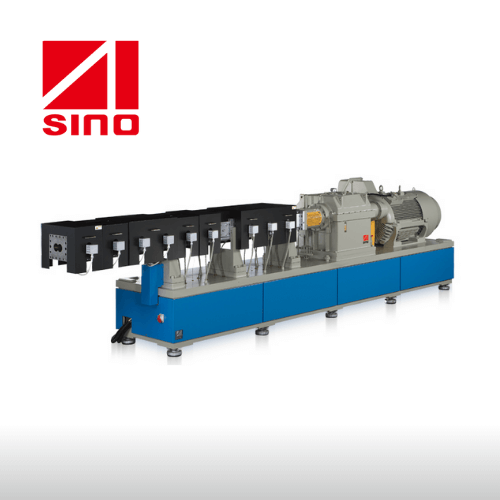

Co-Rotating Twin Screw Extruders-PSM72A

Categories : Twin Screw Extruders

The optimization of the PSM72 series resulted in more efficient and durable designs. The PSM72 series has mid range production capabilities, and easy operation in reasonable price. All PSM72 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

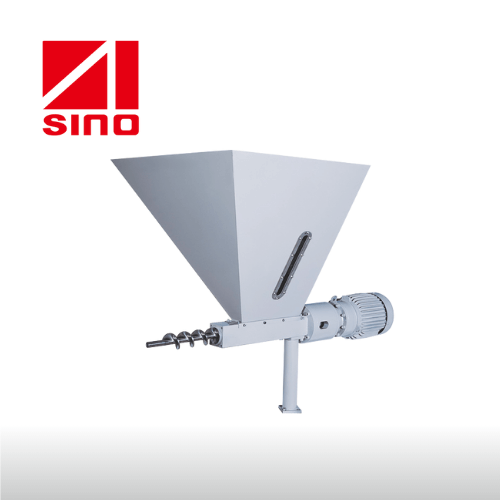

Single Screw Feeder-PSA

Categories : Feeders

The PSA series single-screw feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The PSA single-screw feeder has a large feeding screw chamber for a smooth flow of the feeding material. Options include standard double-flight, single-flight, T-type, and spring type screws, which can be swapped easily and quickly to match the feeding material. The advantages of the intermeshed type of screw pairs are powerful displacement right-angle conveying, self-cleaning of the screws, high feed volume, and stable feeding. Sino-Alloy can also tailor the design of the feeder to match extruders from other manufacturers. Customers can also specify options such as premix, vibrate, preheat or cooling to suit production demands.

Mini Type Blown Film Machine

Categories : Blown Film Extruders

Designed for T-Shirt bag and flat bag production Small occupancy of space Simple, flexible and economic operation High output and saving energy Also can work with LDPE resin if changing air ring Film thickness HDPE 0.008~0.06 mm

Two Stripe Color Blown Film Machine

Categories : Blown Film Extruders

TCP-H is designed by two independent motors, gear boxes and extruders to produce films with two colors stripes TCP-SE is designed by one motor, one gear boxes & two extruders to produce film with two colors stripes TCP-H makes width of two colors can be adjustable TCP-SE is for saving cost of machine & less capacity The precise die design makes the colors vivid, clear & won’t be mixed together Purchasing a 2-layer co-extrusion die can produce 2-layer film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Double lip air ring & better cooling system to support the high speed capacity Can produce LDPE, LLDPE and shrinkable film Slitting device and double winder (up-and-down & back-to-back type) is offered to produce single layer film rolls. Optional Rotating die device is making uniform thickness film for printing & laminating purpose Optional Co-speed controller matches same speed for take-up unit and winder to avoid film to be stretched Purchasing HDPE die can produce HDPE film Fully automatic winder makes machine automatically & save time of operators We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

High Speed Twin Die Blown Film Machine

Categories : Blown Film Extruders

TDH series is one extruder provides two dies to get bigger capacity & less space. TDH-S series is standard machine. TDH-F series is forced feeding type for more output & faster speed. Purchasing extra LDPE die can produce LDPE film.