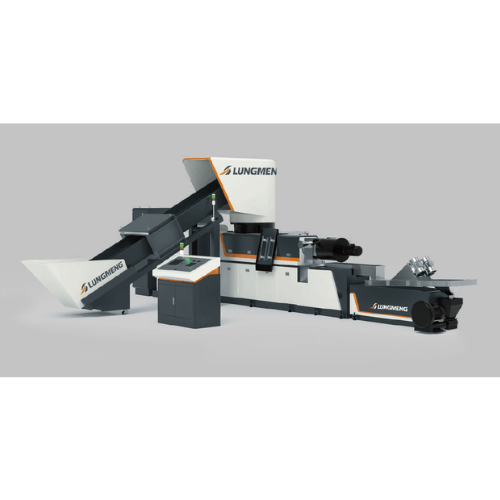

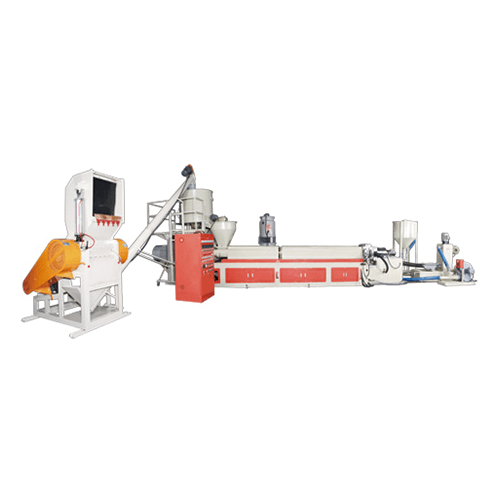

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic Waste Recycling Machines

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

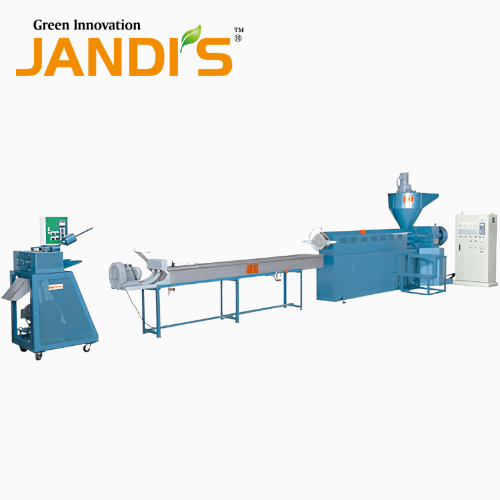

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Side feeding barrel is better for storage and steady material input at same time. Main Extruder can extrude the material whose moisture below 7%. Sub extruder conducts second time filtering and ventilating for dirtier materials. Die face cutting frame made in SUS304 to prevent the rust and corrosion. Knives adjustments automaticlly patent design.The knife and die plate always set at 90 degree. No need to adjust frequently. High speed dryer is soundproof with double layer sealing design. The underneath water tank can gather the waste water and filter the impurity. Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryer. The triple layers vibrating screener is easy to clean, disassemble and assemble. Can customize the diameter of the hole. Blower with noiseless design. Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

Force Hopper Feeding Plastic Recycling Machine (H Series)

Categories : Plastic Pelletizer Machines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost save up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Plastic Recycling Machine - Gator Series

Categories : Plastic Waste Recycling Machines

Applicable materials : HDPE , LDPE and PP. Designed for high material process stability and production. Vent design on the barrel evaporates the volatiles from the recycled material. Hydraulic screen change unit and pressure gauge for easy operation and safety. Water chamber with die face cutter simplifies the process. Easy operation, low downtime and quick maintenance.

PE Waste Plastic Recycling Making Machine

Categories : Plastic Waste Recycling Machines

DIE-FACE CUTTING MODEL(PE)

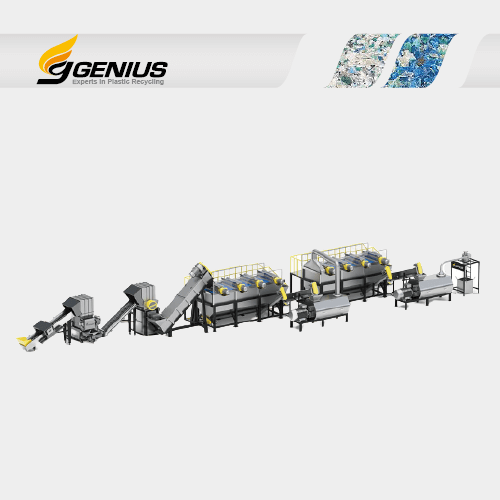

Rigid Washing Line

Categories : Loading and Conveying Machines

The rigid washing plants are designed for recycling post-consumer hard materials like bottles, injection waste, or rigid materials. These systems produce uniform plastic flakes with high purity and low moisture level.

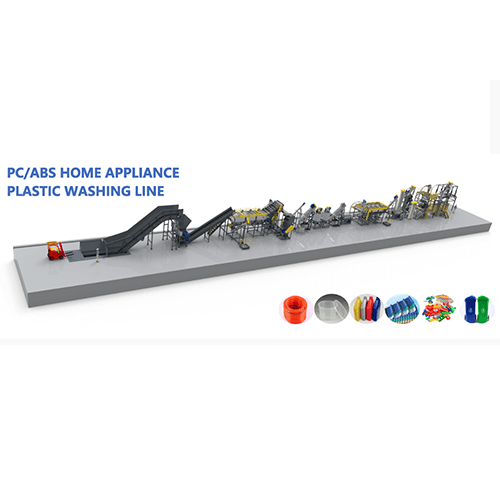

Rigid Plastics Recycling System

Categories : Plastic Waste Recycling Machines

Rigid Plastics Recycling System

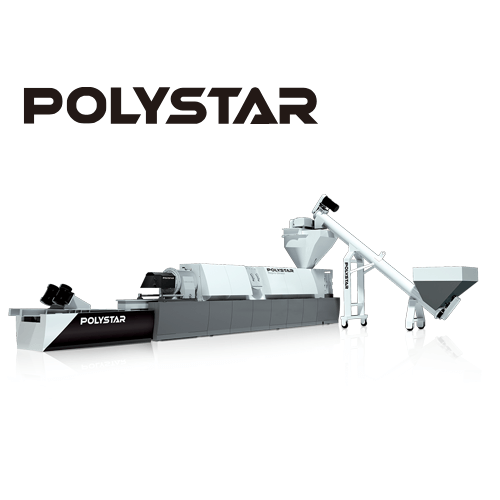

Hard Plastic Recycling Machine: Repro-Direct

Categories : Plastic Waste Recycling Machines

● The Perfect Solution for recycling plastic films waste/ regrind/ granules ● Crusher and conveyor can be added and combined into a complete recycling line

Shredder Integrated Recycling Machine

Categories : Plastic Shredders

Can handle large heavy materials or thin-film materials, such as lump from screen changer, roll material, bulk barrel, containers..., Two-stages filtration makes raw materials cleaner, fully automatic, and reduces the labor operating time. Operate easily. Accept customize., One machine with multiple functions.Solving complicated production, and the adjustment process is fast-High productivity, low noise, Easy operation, Blades removal is easy and reusable

FILM/BAGS WASTE PLASTIC RECYCLING MACHINE : KCR-150

Categories : Plastic Waste Recycling Machines

Each blown film machine is equipped with an electronic length counter and an accumulated time meter. In addition, all main output shafts are precision ground for exceptional stability and quiet operation.

Rigid Plastics and PE Film Recycling System

Categories : Plastic Washing Line

Rigid Plastics and PE Film Recycling System

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

Categories : Plastic Waste Recycling Machines

Water Cooling Type Plastic Film Recycling Machine (GSR-85)