Master-batch Feeder (MF)

Categories : Feeders

The masterbatch mixes with your virgin resin at the machine hopper automatically. You don't need to pre-color nor pre-mix your resin anymore. It saves the manpower, resin, stock costs, and keeps working environment clean. The unit mixes and doses masterbatch, additives, free flowing powders, regrinded and virgin resin to ensure consistent and accurate mixing which results in better quality of product and less rejects. With the special process, the internal part of the unit has no dead corners and makes the dosing process more accurate. Both dosing-cylinder and dosing-screw can be easily changed. The motor feedback control is operated by the tacho-generator which will not be influenced by power fluctuations. It gives the utmost accurate dosing. If some reasons changed R.P.M. of the extruder after setting, the unit will automatically to be changed by the percentage of new R.P.M. By just entering the weight of the materials, screw back time, dosing capacity per turn and additional rate of the masterbatch, the CPU will calculate proper R.P.M. rate automatically. The control panel is user friendly & much more accurate. Besides, it also has the function to store up to 10 sets of R.P.M. setting. To work with the injection molding machines, the unit is also equipped with a timer to control the dosing time.

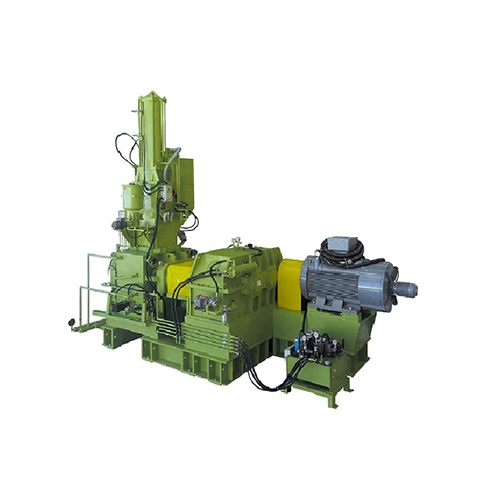

Intensive Mixer

Categories : Rubber Mixers

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber: Drill hole type jacket. Excellent cooling ability. Material contact surface: Hard chrome plating and fine polish. 3.Discharge door: Excellent sealing. No material leakage. 4.Ram: Drive by air cylinder. Good mixing and dispersion quality.

Rubber / Plastic Mixer Machine

Categories : Rubber Mixers

This Intensive Mixer is designed for mixing compounds and specific plastic. The structure of the machine consists of the main air cylinder, floating weight, feeding door, mixing chamber, rotors and discharge device. When performing mixing compound operations, the material and ingredients are fed together into the mixing chamber. The material in the mixing chamber is repeatedly sheared and squeezed by the rotors. This provides a series of chemical rotations between the material and the ingredients, which enables the material pieces to stick together into a paste mass shape. Mixing compound operations are performed according to the set temperature and conditions. This specially designed mixing machine provides efficient mixing and refining for a wide range of raw materials, such as raw rubber, resins, asphalt, cellulose, PVC ane EVA…etc.

Hydraulic Type Die Cutting Machine With Sliding Table Feeding

Categories : Cutting Machines

Four column of hydraulic cylinder, average cutting force. Microcomputer controller for maximum operation convenience. High speed sliding table feeding, motion is fast and safe. Safety sensor is equipped in front of cutter, (when sensor is touched, the machine automatically stops the action). Application:Special design for die cutting one layer or several layers of such material as rubber sheet, leather, plastic, foam, nylon, paper board and synthetic material. yicheen

Hydraulic Automatic Feed Die Cutting Machine (Four Column Press)

Categories : Cutting Machines

Application:Suitable for cutting one layer or several layer of such material as rubber sheet (bottom sole, medium sole), EVA, leather, plastic canvas, vacuum foaming products, nylons, carpet, mat, corks, soft tiles, paper boards and synthetic materials. yicheen The improved and upgraded traditional punching machines. Adopt four column of Hydraulic cylinder, average cutting force, high efficiency to raise the productivity. The upper die install by Magnetic platen, it is very convenient to change die. Microcomputer controller with touch sensing screen for maximum operation convenience and accuracy. Also, optional equipped with LCD screen computer control system is available, which it can memory operation program, provide the most convenient in operation and accurate cutting operation. Lubricated system design on Main shaft to avoid machine parts damage in movement and enhance machine lifetime. The Safety device (opening safe net for emergency stop motion) ensures the operator safety. Options: Air shaft unwind device, Air shaft rewind device

Aluminum Foil Printing Machine(WAP Series)

Categories : Rotogravure Printing Machines

In order to meet the special requirement of aluminum foil printing, the quality and R&D oriented manufacturer-- Worldly Industrial Co., Ltd., has developed the best solution for this special printing accordingly-WAP series. Considering the diverse needs of product printing, Worldly has designed the six-color printing station in printing structure, and combined a coating machine in the terminal. This coating machine has the outstanding capacity to lacquer over aluminum foil after printing to Improve printing effect, and it is also equipped with spine glue function for many different printing requirements. Also, adopts special reverse structure for aluminum foil between each color printing station, and sets up doctor blade units on both sides to enable reverse printing in any color. Easily fulfills various requirements in printing. Besides of that, adopts "Sumimoto" sectional motor system in every printing station; therefore, saving operation time and improve effect/respond time of color register during printing cylinder replacement. This machine also equips a drying tunnel system on the top of it. It is a four-sectional drying tunnel which makes drying more efficiently. Unwinding and Rewinding units are splicing materials in double shaft automatically turret type. And it is non- stop the machine when changing materials, very simple and convenient. All machine is link-controlled by High-efficiency PLC logic controller and HMI touch interface, so the controlling effect is very precise and high efficient. In addition to that, this machine also equips with automatic color register function which makes printing quality beyond perfection. As for Q.C, Worldly selects VIDEO monitoring system to achieve real-time Q.C inspection. It effectively assists printing work and improves quality Even if in high speed printing operation.

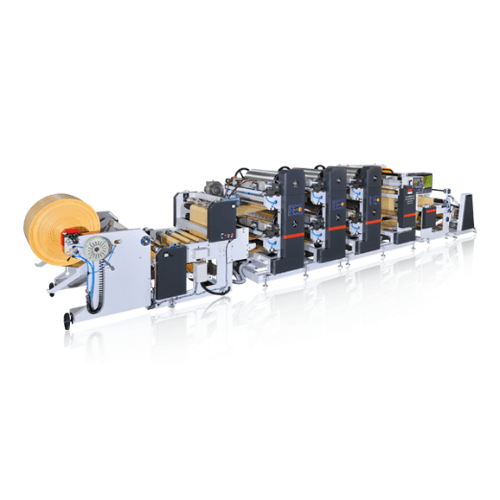

Flexo Stack printing Machine PKF-8 Series

Categories : Flexographic Printing Machines

● Machine framed with 50MM cast metal plate, provide a very steady, vibration free foundation for the printing work. ● All gears are helical design. ● AC main motor from Siemens and controlled by Japan made inverter to provide a steady speed performance. ● Inking rubber rollers are driven by European made hydraulic motor independently, speed can be adjusted for controlling ink transfer volume. ● Simple but accuracy and steady vertical and horizontal image adjustment device. ● Long arch type drying tunnel with high capacity blower, to allow ink quick drying during high speed operation. ● Bearing house design for holding rubber roller, plate cylinder and anilox roller. ● Machine can be equipped with Japan auto tension controlling system, close chamber doctor blade, EPC at unwind, rewind as optional choice. Flexo Stack printing Machine Flexographic printing machine CI Flexoprinting Machine Flexographic Printing Machine FLEXOGRAPHIC PRINTING MACHINE FLEXO PRINTING MACHINE FLEXO STACK PRESS FLEXO PRINTING PRESS CI PRINTING PRESS CI PRINTING MACHINE PAPER PRINTING MACHINE PAPER PREPRINT PRINTING MACHINE OFF LINE PRINTING MACHINE

Flexographic Printing Machine for PP Woven Bags

Categories : Flexographic Printing Machines

● The BOTHEVEN Flexographic Printing Press #MP Serial is design for fabric sheet printing, such as after cutting and bottom sewing of laminated or un-laminated bag, paper bag ....etc. ● Easy operation, easy change printing plate. ● Special design a Action Roller dispense device, the printing cylinder won't dirty conveyor when empty load.

Bottom Seal Bag Making Machine + Bag Folding System

Categories : Plastic Bag Making Machines

Automatic Folding system - Servo-controlled 1st & 2nd fold individually (piece by piece), 3rd fold by pneumatic cylinder every 1-15 pieces pile. 4th & 5th folds by optional. Cold-cut system - For thin film material. Machine uses upper heating knife and silicon roller base for sealing. Cutting knife before bag outfeeding.

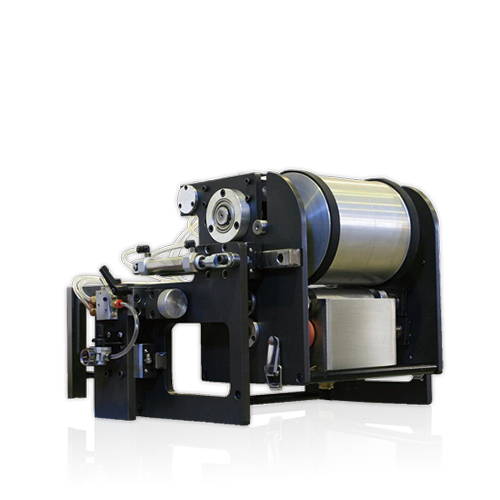

Mini Flexo Printing Machine: LW-LF100-E Model (Plate Cylinders Changeable)

Categories : Flexographic Printing Machines

Plate Cylinder size changeable from 500mm to 800mm repeating printing length, standard equip with 500mm plate cylinder, Portable flexographic printing machine, suitable for printing the marks, logo, literature, and various kinds of one color printing purpose. Passive type machine install on the extruder, bag making machine and any kinds of conveying type equipment, thru the films flow to drive the printing head no power supply required economic and easy operation.

Reel to Reel Flexographic Printing Line FSRP-6C (No Cylinder Changing)

Equipped Servo Motors for Precise Printing Graphic and Printing Length Control On-line Servo Control Printing Position Registration System (with Touch Screen Operation) (Each printing station equipped with servo motor to adjust printing position during machine running) Equipped with On-line Camera Inspection (Italy made) Two Units, Monitoring Printing Quality during Machine Running. Equipped with Doctor Blade System and Ceramic Anilox Roller as Standard Equipment

Medical Waterproof Disposable Table Paper Cutting Machine Model SHCG-42MP

Categories : Paper Bag Making Machines

The paper bag cutting and making machine features 1. Servo Motor Driven for precise length cutting. 2. Infeed Dance Roller Control with inverter Motor. 3. Air Cylinder Lifter Heavy Duty Unwinder for 300KG Paper Roll. 4. Collect Conveyor for friendly operation.