Two Platen Injection Molding Machine NRH Series

Categories : Horizontal Injection Molding Machines

20% ~ 30% less from machine length, compare with toggle design. Less space required from a molding facility. Less space required from a molding facility. Fully automatic mold-close adjustment ready to reduce time required from mold change. Paten #I279312, Intellectual Property Office, MOEA, Taiwan. Available option for additional stroke from opening. Spare the larger machine needs for bigger opening stroke. Available option with Retractable Tie-bar function. With additional mold lifting module to accommodate jumbo machines in regular facility height. Extended Die service expectancy without deformation thanks to hydraulic cylinder clamping parallelism. Shortened high-pressure clamping stroke thanks to ability of fast building clamping force.

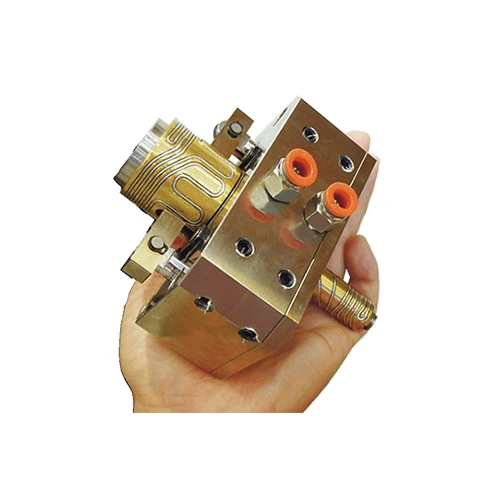

Single Valve Gate Hot Runner System

Categories : Hot Runner Systems

Dual-cylinder, powerful for gate seal. Nice gate mark. All in one, easy to install. Customize for your need.

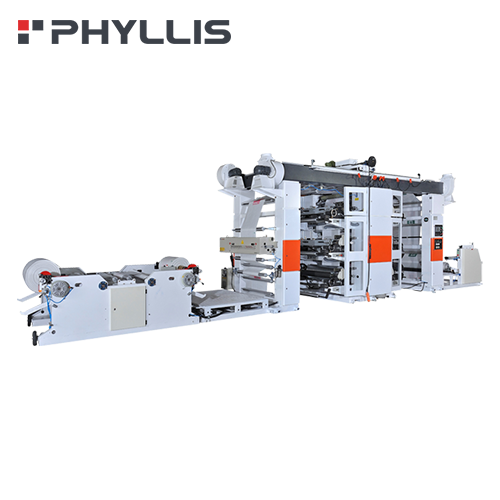

Flexographic Printing Machine (Roll to roll)

Categories : Woven Bag Printing Machine

Flexographic roll-to-roll printing machine for coated and uncoated tubular PP woven fabric and film. Advantage of using same printing cylinder with various bag lengths. Easy touch screen operation with doctor blade system for high quality printing with minimum ink consumption.

Vertical Clamping Vertical Injection Machine-YH Series

Categories : Vertical Injection Molding Machines

- Four-column/vertical clamping, vertical injection. Rectangular shape between tie bars for easy insert. - Twin injection cylinder balanced for smooth and powerful injection. - Simple structure, small occupancy. - Double action clamping cylinder for fast clamping, slow speed high-pressure clamping. - Single sliding pushes the lower mold out for easy loading/unloading. - Double sliding use two lower mold, machine molding the parts while the operator is loading the other mold, to increase productivity.

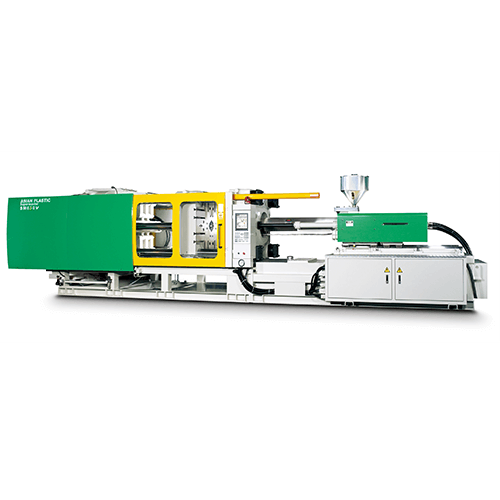

Heavy Duty Double Toggle Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision. The injection carriage uses a balanced double hydraulic cylinder to provide a secure hold between the mould and the nozzle to eliminate nozzle leakage. Linear guide ways reduce mechanical friction, decrease machine wear and increases accuracy over back pressure providing better control of the injection sequence. Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportional valves is more precise resulting in more accurate control.

Precision Four-Column Plan Hydraulic Cutting Machine-CSS-202B

Categories : Foaming Machinery

●The body of the machine is made of special steel and has gone through rigorous processing that shows a ram pressure-resistant function and precision. ●Up and down stroke applies steel pole as the rail that brings out an effect of high precision and shaking-resistant characteristic. ●A design of Two-pod oil cylinder shows the stable force and large torsion.

High Speed Injection Molding Machine (TSV Series)

Categories : Hydraulic Clamping Injection Molding Machines

• The double hydraulic cylinder provides secure hold on pressurefor the injection carriage eliminating nozzle leakage. • The toggles are lubricated with the graphite bronze bushes to ensure lower friction wear, assure greater accuracy and greatlyextended life of the clamp unit. • Fast clamping system equipped with regeneration circuit increase speed by 60% to shorten cycle time and save energy. • Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportion-al valves is more precise resulting in more accurate control.

Vertical Two Tie-Bar Injection Molding Machine

Categories : Hydraulic Clamping Injection Molding Machines

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production, then reduce the cost of production. High precision mold platen (Parallelism/flatness:0.01/100mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact, space-saving design, reduce the heavy burden of the floor of factory.

Vertical Single Shuttle Table Injection Machine

Categories : Vertical Injection Molding Machines

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.