Vertical Shuttle Table Injection Molding Machine

Categories : Vertical Injection Molding Machines

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie-bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

Vertical 4-TIE BAR Injection Machine

Categories : Hydraulic Clamping Injection Molding Machines

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.01/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

C Type Injection Molding Machine

Categories : Vertical Injection Molding Machines

Tie-bar less (C type) design gives more space for operation. Especially suitable for the power cord and connector with wire. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , thus reduce the cost of production. High precision mold platen ( Parallelism/ flatness : 0.01/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitrite and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, resolve the floor space shortage problem of factory. Material injected through parting line to cavities.

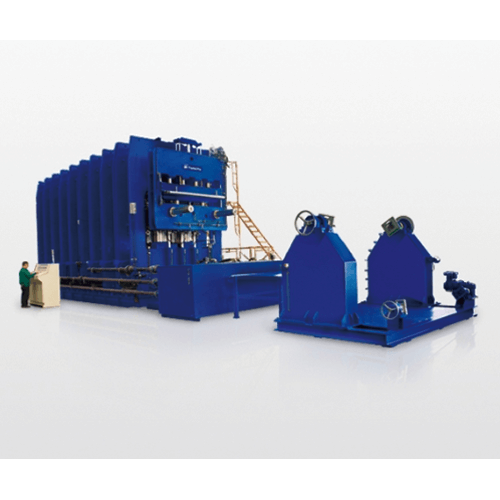

Steel Cord Conveyor Belt Vulcanizing Machine / Line

Categories : Rubber Curing/Vulcanizing Machines

Custom design Jumbo Size (large tonnage) vulcanization press equipment available, production capacity up to 13000 tons. Equipped with cooling system on the bottom of cylinders to prevent oil temperature increase and maintain better endurance operation. The bottom of cylinders is contacted to platen with full pressing area to have even pressure and better product quality.

Auto Re-Bonding Machine With Auto Loading And Unloading System

Categories : Loading and Conveying Machines

Especially designed for bonding granule foam chips into rectangular blocks to make cushions, mattresses, pads or peeling cylinder blocks into endless sheets or carpet underlay.

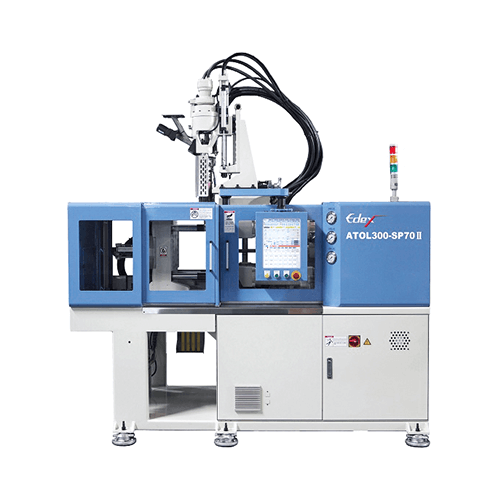

ATOL- Horizontal Multi-color/resin Injection Molding Machine

● Single, dual, triple color/resin in one machine. ● Suits for Plunger type injection or screw type injection system. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Intelligent program controller makes injection easier. ● The shortest injection molding machine. ● Precise energy-saving hydraulic system.

JS Series-Double Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Plastic Blow Molding Machine. ●Automatic production design. ●Mold Open/Close/Move by cylinder. ●Gearbox drive extruder system. ●PLC control with Touch Screen for function, time, pressure...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Proportional pressure hydraulic system. ●Especially for 2 liter bottle and 5 liter bottle.

VTOP- Vertical Plunger Type Injection Molding Machine

Categories : Automatic Injection Molding Machine

● Patented interchangeable 3-in-1 modular slide table design. ● Capable of producing precise micro products as 0.001-0.0001 gram products. ● Patented active bypass auxiliary plasticization system design. ● New design patent-IPIS (Interchangeable Plunger Injection System). ● Plunger Type Injection can highly save resin runner. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Dual protection of safety door and safety light curtains. ● Intelligent program controller makes injection easier. ● The lowest table height injection molding machine. ● Precise energy-saving hydraulic system.

Overload Protector

Categories : Mold Protection Devices

FUNCTION Overload Protector is equipped in Press machine to check hydraulic pressure of cylinder inside the slider. If happen overload, the hydraulic pressure of cylinder will be released immediately within 3/1000 seconds. When happen overload, in order to protect the press and die, the press will stop working immediately after receiving the signal from limit switch. After happen overload, the air will drive hydraulic pump to supply normal working pressure immediately and the press can work normal. It has pressure control valve inside of overload protector, which can adjust hydraulic pressure automatically and eliminate the impact of rising pressure (which cause by oil temperature rise) in pressing process. May select different types of components and control units base on the different types and specifications of press machines.

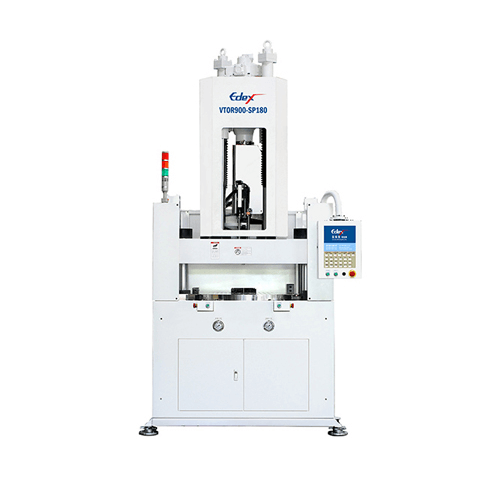

VTOR- Vertical Rotary Injection Molding Machine

Categories : Automatic Injection Molding Machine

● The smallest rotary table design, max mold diameter. ● Suits for Plunger type injection or screw type injection system. ● Patented active bypass auxiliary plasticization system design. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Safety light curtains protection. ● Intelligent program controller makes injection easier. ● The lowest table height injection molding machine. ● Precise energy-saving hydraulic system.

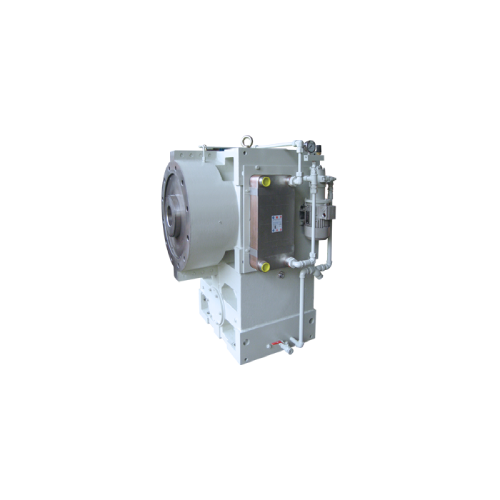

for Extruder Machine - Single Screw Tex Series

Categories : Gearboxes

CASE Material: FC 25 module cast iron GEAR SHAFT a. Material : SNCM220.Carburization & Hardness HRc56∘~60∘ b. Gear precision: reach JIS 2 level GEAR Material: SCM420 Carburization & Hardness HRc56 ∘ ~58∘ b. Gear precision: reach JIS 2 level OUTPUT SHAFT Material: SCM440 Hardness: reach HRc28 ∘ ~32∘ High Frequency Heat Treatment in HRC 48〫-52〫 in the connected area of Oil Seal Bearing Brand : SKF 、FAG、NSK (OPTION), Oil Seal : NOK or SKF Brand, material: Viton Lubrication System : OIL BATH SPLASH TYPE Forced type (Elements including as below) Motor PUMP(1HP/220/380V+Rop210HA) Teco Brand Cooling device(plate type) or Cylinder type Y Type Filter Temperature Gauge Pressure Gauge Pressure Switch Gear Measuring Report : Lead/Profile/Pitch testing Report Operation temperature rising: below +40 ℃ (Ambient temperature) Operation Vibration < 2.3mm/sec Operation Sound < 80Db, None Oil Leakage

Double Toggle Injection Molding Machine (SMV Series)

Categories : Horizontal Injection Molding Machines

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Multi steps injection pressure and speedcontrol. • Steel bushes have a hardness of HV800 for wear resistances. • Auto-lubrication system is provided to assure the constant lubrication of the toggle mechanism • Multi-stroke hydraulic ejector ensures positive ejection of the product and enables unmanned production with or without the use of a robotic arm. • Differential hydraulic circuit shortens cycle time and saves energy. • Low pressure mold protection system was used to avoid mold damage or excessive wear.