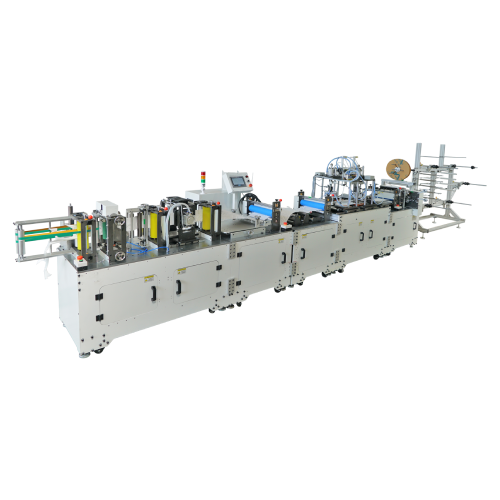

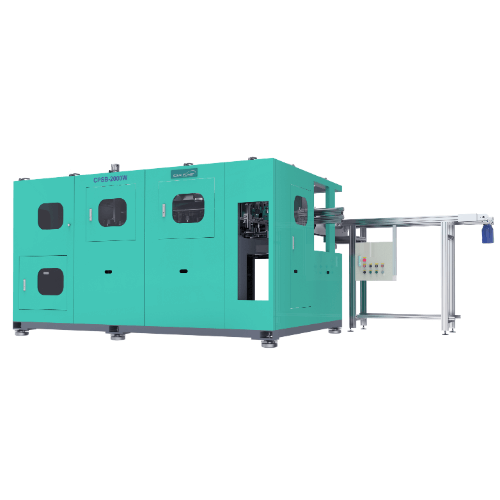

PET Fully Electric Stretch Blow Molding Machine

Categories : Electric Blow Molding Machines

A handle bottle makes it easier to carry and pour from a container to container. CMS series stretch blow molding machine equipped with a robot device is the choice of making bottle with handle. The container with a firmly fixed rigid polypropylene handle ensures the shape that does not been distorted, and it is currently used for new products, especially for family size packs.

Large Volume PET Blow Molding Machine-W/L Series

Categories : Automatic Blow Molding Machines

Large Volume PET Blow Molding Machine-W/L Series Robust hydraulic clamping.Double robotic arms for speedy preform loading.Cost Effective machine that is also easy to maintain.Compact structure for small floor foot print.Modular design for easy maintenance.

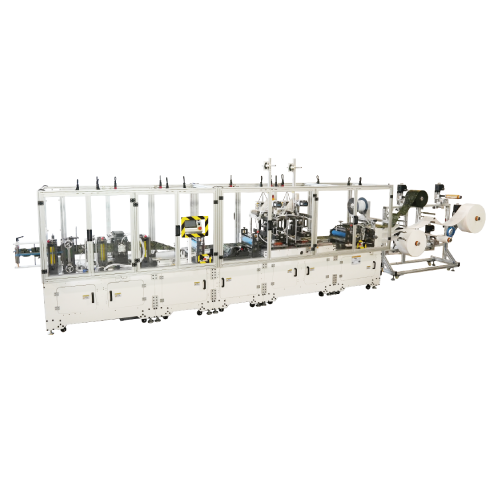

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Automatic Blow Molding Machines

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and for applications where stringent quality requirements have to be met. Substantial reduction in operating cost is achieved by saving of manpower.

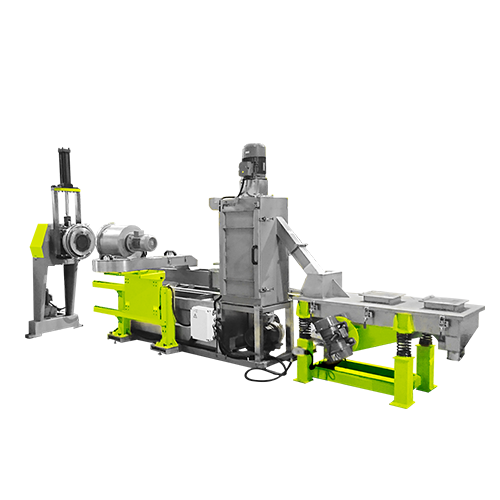

Strand Pelletizer-PSH

Categories : Plastic Pelletizer Machines

The PSH strand pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Strands from the extruder are pulled through a water-filled cooling bath and blown dry by an air knife before entering the pelletizer. This simple pelletizing process is applicable to many different types of plastics and rubber. Our knives are made with tungsten carbide steel to ensure a long life and clean cuts. Puller and rotary knife can be synchronized to ensure uniform pellet size regardless of the extruder throughput. Designed with built in safety features, the moving parts are all enclosed within a protective cover.

Hot Die Face Pelletizing System

Categories : Plastic Pelletizer Machines

Cost Reduction The molten polymer from the extruder is passed to the die head. A rotating blade cuts the hot material as it exits the die hole and falls into a water ring for cooling. The operator does not need to draw the strands, which reduces the lump waste during re-drawing. More Uniformity, More Profit The pelletizing cutter is a universal joint design. The cutter adjusts the blade automatically during operation. Final plastic pellets are in uniform size in order to be sold at a higher price and bring you more profit.

Granulating System: Water Ring Pelletizer System

Categories : Plastic Pelletizer Machines

Structure and function of our plastic water ring pelletizer system and machine. Features and advantages of our plastic water ring pelletizing machine line. Applicable plastic materials of our plastic granulating series system and machine. Mainly used for plastic materials such as LDPE、HDPE、PP etc.

Blow Molding Machine PBS-605~705 Series

Categories : Horizontal Blow Molding Machines

Durable and horizontal traveling mold carriage combined with German linear motion guides for maximum stability. The series is excellent for producing medium and large sized containers. Available to equip with an auto deflashing device and take-out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

Heavy Duty Crushing Machine - Silent Type C-300STC-560ST

Categories : Plastic Crushers

• Fully enclosed stainless steel casing. • Convenient access doors on five sides. • Dual layer insulation for substantial noise reduction.

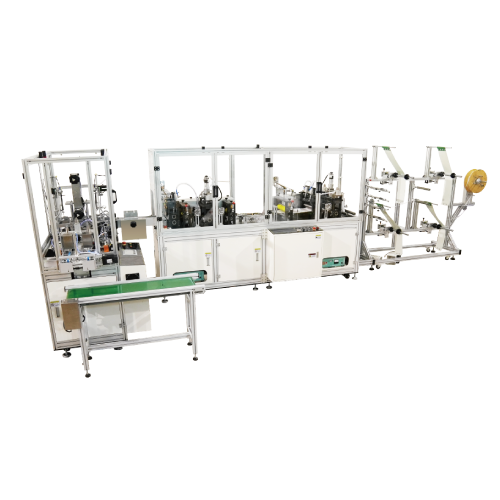

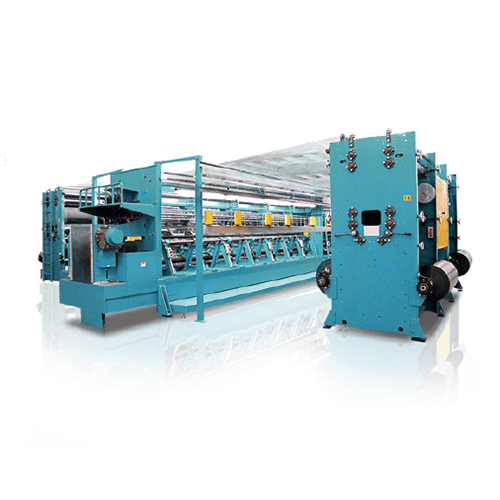

Double Needle Bar Raschel Machines

Categories : Industrial Knitting Machines

High-Speed Double Needle Bar Raschel Machines for Manufacturing Packing Sacks .Onion bag machines: (so-called "ready-made sacks" for packing orange, lemon, potato, ...etc.). .For special wide nets. .For double layered nets.