Energy-efficient Hopper Dryer-SEHD

Categories : Dryers and Dehumidifiers For Plastic Materials

The SEHD energy-efficient hopper dryer can be used for drying most non-hygroscopic materials, such as PS, PP, ABS, etc. The maximum drying temperature can reach 160℃ and it also can choose the optional double-layer insulation model to obtain uniform hopper temperature with less heat losses. Besides, multiple components are available as options that can recycle the hot air and filter the iron impurities in the material, which also can be installed on the ground with the floor stand.

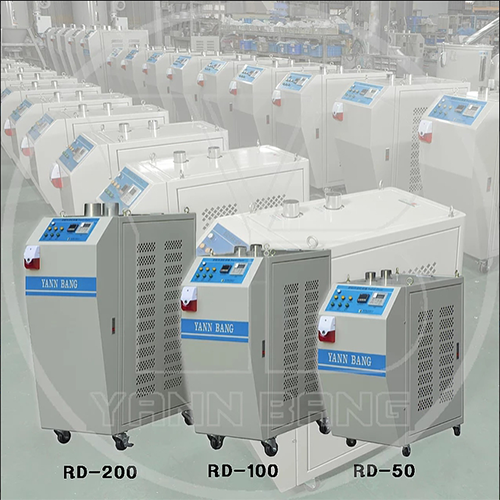

Rapid Dryer (RD)

Categories : Dryers and Dehumidifiers For Plastic Materials

Without replace your old hopper dryer, use this new dryer to dry faster with better quality and to upgrade production more efficiently. 1. Wide application. Suit to numerous material such as PC, PMMA, PA46, PPS, NYLON and some PET/PETG. 2. Save time and energy. Patented technology significantly shortens the drying time. Normally NYLON takes four hours to dry. Work with Yann Bang’s rapid dryer (RD), it only takes two hours to dry completely and ready to use. RD can decrease 50% of drying hours and save 50% of energy for you. 3. Upgrade energy save. Combine with Yann Bang’s Energy-efficient Hopper dryer can save more energy obviously. 4. Increase yield rate of output. Moisture content can be reduced to 0.02% (depend on the initial moisture content of resin), improve the drying quality of resin, and lower defective products. 5. Easy maintenance. Install with plug-in air filter and dust collector (oil collector) that you can unload easily to clean and replace parts.

Cabinet Dryers - CD

Categories : Dryers and Dehumidifiers For Plastic Materials

CD series of cabinet dryers are mostly used for simultaneous drying of different kinds of polymers in small quantities or for drying materials for trial molding. They can also be applied in electronic engineering, electroplating, pharmacy, paint baking, printing industries, etc. for preheating or drying related products.

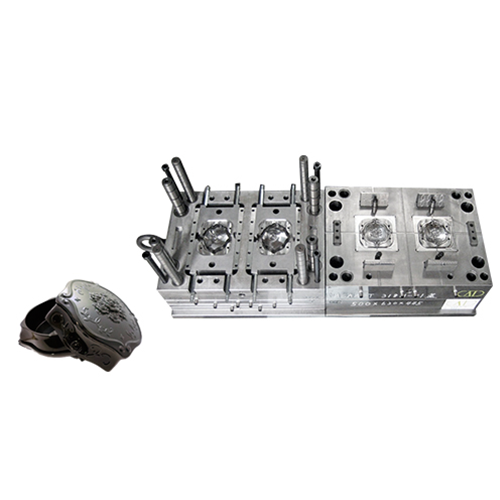

Plastic cosmetic moulds

Categories : Injection Molds

Mold size: 500 x 620 x 445 mm Mold weight: 885kg Injection machine: 260Ton Surface: Mirror polish & carving

Screenless Granulators - SG-14/24N/24T

Categories : Granulators

SG-14/24/24T series granulators operate in super low speed to cut materials into well-proportioned granules. There are least dusts produced in the cutting process. Multiple security devices ensure high safety grade; automatic reverse running function ensures continuous operation. This series of screenless granulators are suitable for granulating hard and thick materials. For SG-24T series, there are two gear motors and two cutting chambers to work simultaneously. It can not only granulate the sprues and waste material, but also has an effect on long and thin or tougher sprues materials.

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Crushing, Washing And Drying Whole Plant Facility For Plastic Film

Categories : Plastic Crushers

Suitable for different kind of plastic materials, e.g. plastic scrap and plastic shampoo bottle. Suitable for different kind of plastic materials, are able to separate high density and dirty material. With high speed washing machine, enable plastic materials inside the machine to be twisted, separated high density and dirty material and washed it for further use. Whole set of electric facility are with automatic startup to protect wires in safe. Optional Equipment: GEORDING unique design Vertical dryer & Centrifugal dryer. With Centrifugal Dryer, single screw rubbing drying machine can separate mud/dust, and dry material efficitently, making the product 3% under moisture. You can opt to have 3 water tanks, depending on how dirty material is. Customize GEORDING could help customer build and modify according to individual specifications.

Plastic Squeeze Dryer (DW Series)

Categories : Plastic Washing Line

Lower moisture, higher capacity A plastic squeeze dryer is a vital part of the plastic film washing line. Washed films retain up to 30% wetness normally. High humidity will be affecting the efficiency and production of the following pelletizing process. Having a plastic squeeze dryer is a must to dehydrate the washed film, reduce the volume of recycled materials, and refine the final plastic pellets' essence. Final moisture less than 1% ↓ after processed. GENIUS

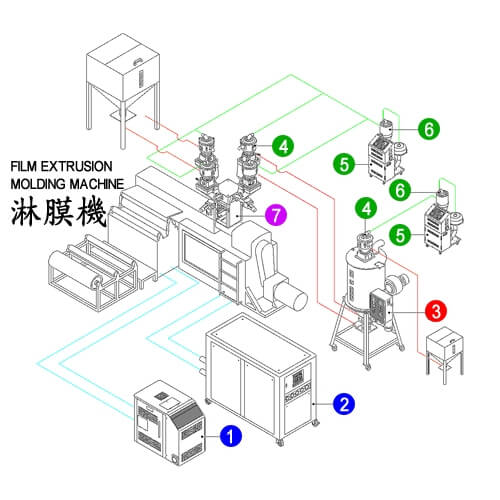

Film Extrusion Molding Machine Auxiliary Solutions

Categories : Assembly Systems

We have a wide range of auxiliary equipment for film extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

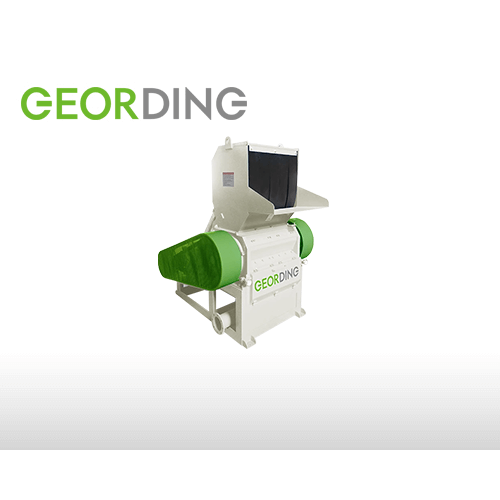

Plastic Bottles Crusher

Categories : Plastic Crushers

The round and hollow frame structure alows big processing volume. The capacity is 3 times more than the average type crushers. The round and hollow frame structure alows big processing volume. The capacity is 3 times more than the average type crushers. Well-designed angle cutters enables you to properly monitor and run easily the machine making the output estimate for other process. With water cooling system and clearance between cutters makes it easy for heat dissipation that helps reduce damage effect between bearings and machine body. Hardened crusher blades. The adapted ball bearings provide strong friction resistance, good centering and anti-vibration.

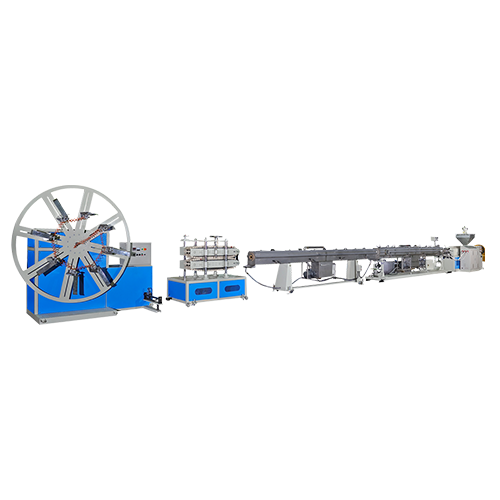

PE/LDPE Pipe Making Machine

Categories : Extrusion Lines For Pipes and Profiles

PE/LDPE Pipe Making Machine

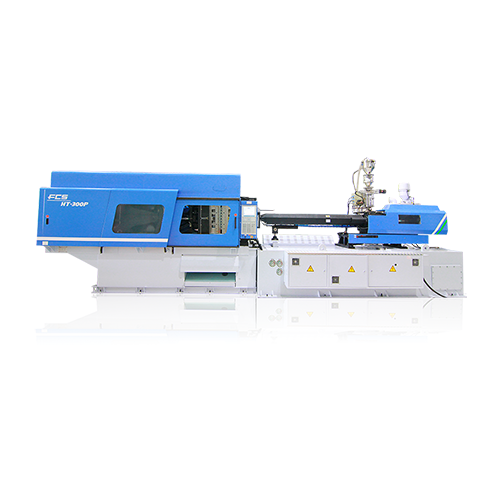

PET preform Injection Molding Machine (PET Series)

Categories : Horizontal Injection Molding Machines

It is PET preform injection molding equipment, which is suitable for mineral water, carbonated beverages, fruit juices, edible oils, medicine jars and lotions, cosmetic packaging containers, etc.