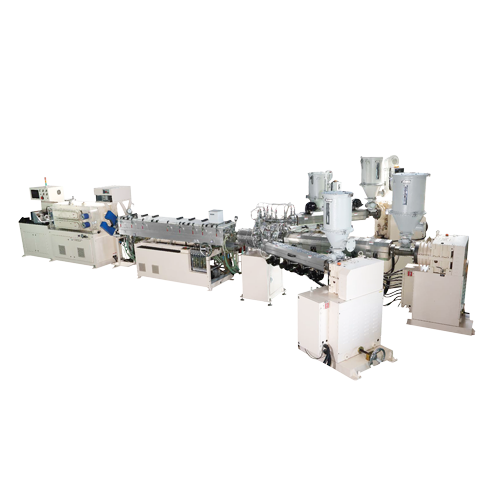

High Speed Multi-layer PE Tube Extruder and Cutting Machine EDC-16-05

Categories : Cutting Machines

-High speed & high output -High precision thickness control on each layer of tube -Simplified control -Quick tooling change by one operator -Closed loop cooling water circulation system -Caterpillar haul-off -Automatic outer diameter control unit (optional) -Low power consumption and high production efficiency

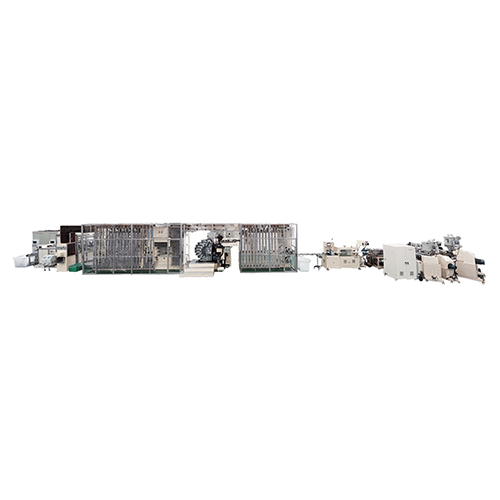

Automatic Accumulator & Transfer Control System

Categories : Extrusion Coating Machines

Automatically storage functions. Available to connect with outer diameter control unit, to separate / remove defect tube via conveyor, not into accumulator. Automatically separate / remove tubes when accumulator fully loading. Automatically transfer tubes to printing machine and heading machine.

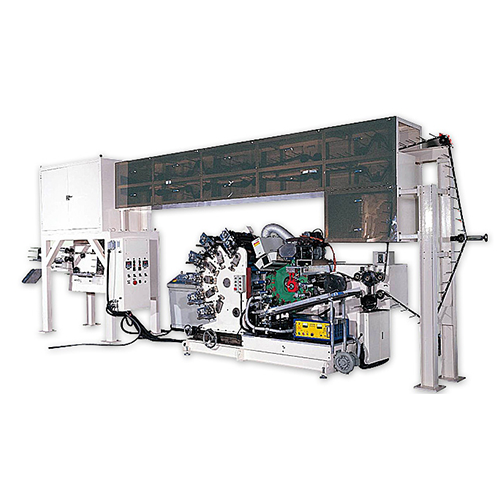

6 Color PE Tube Dry Offset Printing Coating Machine PCD-80-06-UV-L

Categories : Extrusion Coating Machines

For left oven design, there’s no space limit, which benefits tube withdrawing and in-line connection in the future. Transferring tubes automatically can lower blowing noise. This model is equipped with an extra device-sleeve printing without shoulder, and customers can choose either function when printing and save cost.

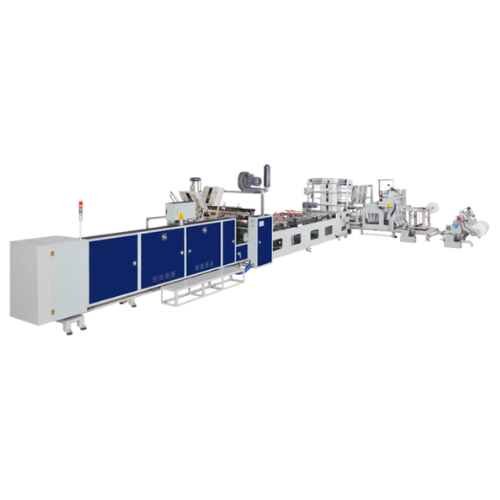

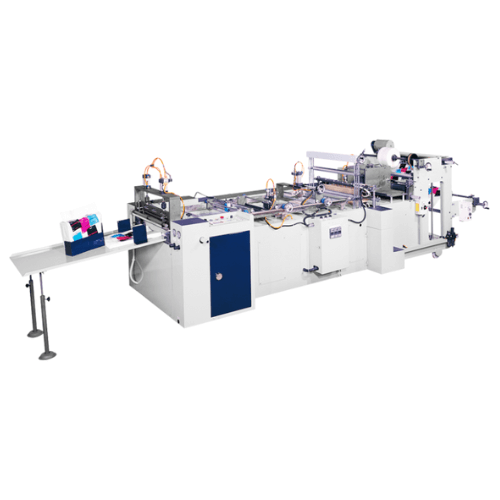

Fully Automatic Side Sealed Diaper Bag Making Machine with Wicketer LY-1250EDW

Categories : Plastic Bag Making Machines

- Fully automatic side sealing type diaper bag making machine with wicketer. - 2 sets of servo motors for feeding system. - 2 sets of servo motors for punch position and indexing station alignment. - 1 set of servo motor for indexing station position control. - 6 or 8 vacuum arms depends on size of bag. - Human-machine interface for easy setting. - Pneumatic type auto-lifter and EPC at unwind stand. - Continuous hot-air sealing system handle film. - Precision mold for handle punch.

Fully Automatic Patch Diaper Bag Making Machine LY-650JD

Categories : Plastic Bag Making Machines

LY-650JD is a specialized bottom sealing type diaper bag making machine which equips with reinforced-patch film sealing unit. Other accessories like easy-tear punch, round type perforation punch are available for option.

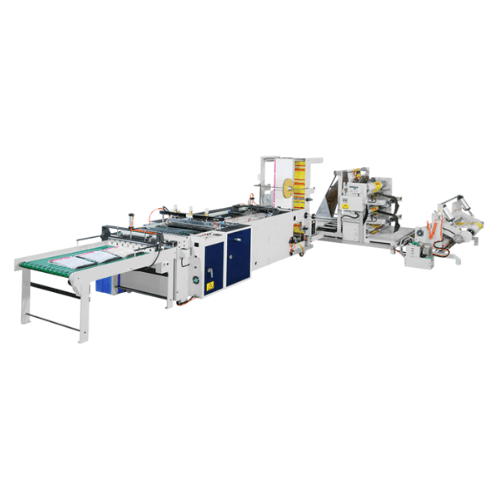

Fully Automatic Side-Sealed Diaper Bag Making Machine LY-1250ED

Categories : Plastic Bag Making Machines

Introduction LY-1250ED is a specialized European-style diaper bag making machine. Customers can use it to manufacture various kinds of diaper bag, allowing flexible and stable production. Features Fully automatic side sealing type diaper bag making machine. Servo-driven feeding system with one set of photocell for printed bag. Human-machine interface for easy setting. Pneumatic type auto-lifter and EPC at unwind stand. Continuous hot-air sealing system handle film. Hydraulic type EPC for wicket holes. Precision mold for handle punch.

Micro Dehumidifying Dryer (DHM-SL )

Categories : Dryers and Dehumidifiers For Plastic Materials

The latest micro dehumidifying dryer uses compressed air to dry the plastic resin. The air volume generated by the air compressor is suitable for the production of small parts, such as electronics parts. The perfect grade of dryness coupled with a moderate amount of drying air, the production efficiency greatly increased. Air compressor process the air via water filtration, and the air will be compressed between pressure 5~7kg/cm² . The compressed air will then go through the molecular sieve and supply the dry air with dew point up to -40 ~ -50 ℃. During the molding process, it will fully demonstrate the perfect plastic properties. In accordance with the different types of plastic, the drying time required is also slightly different, for 2 to 6 hours. The multi-function design can dry, dehumidify, and automatically convey resins. Comparing to the regular dehumidifying dryer, it can save space and directly connect to the inlet of molding machine. It can directly convey the drying resins to production to prevent resurgence and to ensure the production complete. 1. Display the dew point detection 2. Insufficient air pressure detection 3. Built-in positive pressure conveying system 4. Overheat preventer 5. Weekly timer 6. Install high-density filter 7. With Industry 4.0 features, Ethernet and RS485 can be used to connect with other brands. 8. The controller and main body can be separated or combined to facilitate for space arrangements.

Multi-function Dehumidifying Dryer (DHC-NA)

Categories : Dryers and Dehumidifiers For Plastic Materials

Multi-function Dehumidifying Dryer (DHC-NA) Three-in-one design can dry, dehumidify, and automatically convey resins, save money. 1. Low noise to promote the quality of environment. 2. Easy to move. The unit with wheels can move anywhere for your need. 3. Designed structure to save more space for use. 4. Combine drying and dehumidification system to save energy and lower carbon emission. 5. Air filter and pipe cleaning device are easy to take out without any tool to save your time. 6. Hopper Dryer made by stainless steel with clean door for easy maintenance.

Fully Automatic DHL Courier Bag Making Machine LY-800DHL

Categories : Bag Making Machine by Applications

- Servo-driven feeding system with one set of photocell for printed bag. - Human-machine interface for easy setting. - Auto-lifter unwind stand with edge position control for jumbo roll. - Continuous hot air sealing system for outer pocket. - Triangle folding device. - Self-adhesive tape applicator. - Auto tension control. - Other options are available depends on sample bag.

Fully Automatic PET Stretch Blow Moulding Machine-CMS(C) Series

Categories : Electric Blow Molding Machines

PET Fully Electric Stretch Blow Molding Machine Series for Cosmetics Bottles

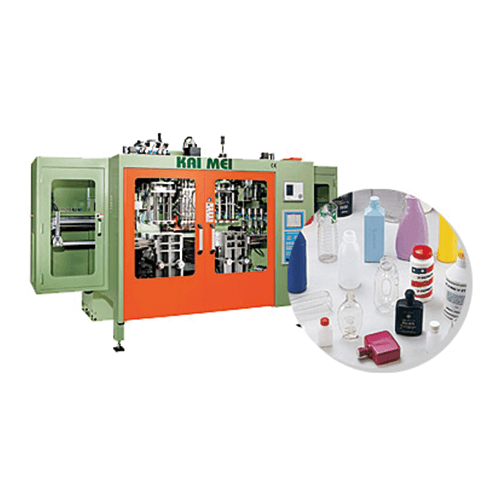

Blow Molding Machine PBSS SERIES 605 / 705 (S / D / T / Q)

Categories : Injection Blow Molding Machines

Double Stations Series Double station machine, full automatically, suitable for producing high-production runs of medium size bottles, ex. Cosmetic bottles detergents, etc. Mold-platen moves properly with high stability and high efficiency Three tie-bar horizontal traveling mold carriage combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production and small size container requirements. Available to equip with auto de-flashing device and take out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, convenient and user-friendly operation.

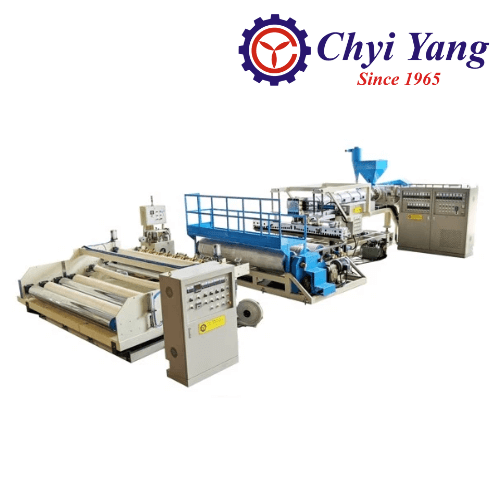

PE Stretch Casting Film Extrusion Machine

Categories : Film and Sheet Extrusion Lines

T-Die Extruder machine can produce waterproof PE film for baby diaper, sanitary napkin, folders, table cloths, medical film, etc. Film thickness 0.03~1 mm Equipped with a fully automatic winder with cutting and changing rolls functions Hydraulic screen changer for short maintenance stop We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.