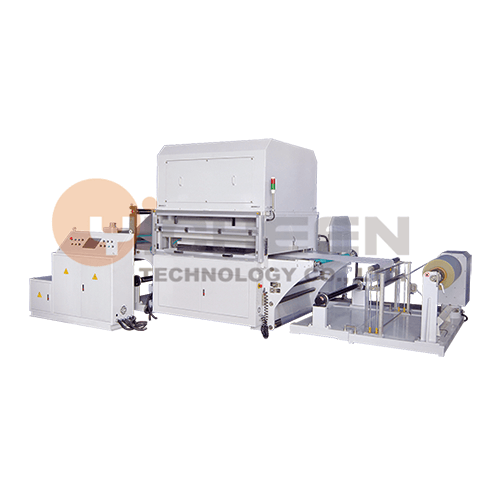

Hydro Dipping Machine - Semi-Automatic - YHT222AXF

Categories : Hydrographic / Water transfer Machines

Dipping Tank + Auto Film Layer + Auto Spray System Dipping Tank 2 meters length. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

High Precision Die Cutting Machine (Full Electrical, One Sheet Feeding)

Categories : Cutting Machines

Application:High precision die cutting machine (Full electrical, one sheet feeding) yicheen

Hydraulic Type Die Cutting Machine With Sliding Table Feeding

Categories : Cutting Machines

Four column of hydraulic cylinder, average cutting force. Microcomputer controller for maximum operation convenience. High speed sliding table feeding, motion is fast and safe. Safety sensor is equipped in front of cutter, (when sensor is touched, the machine automatically stops the action). Application:Special design for die cutting one layer or several layers of such material as rubber sheet, leather, plastic, foam, nylon, paper board and synthetic material. yicheen

High Precision Hydraulic Type Die Cutting Machine

Categories : Cutting Machines

Application:Plastic films, such as diffuser, reflects sheet, brightness Enhancement Film, PET, PE, PVC, Paper, Self-adhesived label…etc. yicheen Max. cutting square is 1500x1500mm. PLC computer touch-panel screen control system – clear & easy in operation. Equipped with high precision mold high fine adjustment control, Four-columns can be micro-adjusted independently by computer setting parameter, to save time and to raise the production rate. Precision die cut position matching; save time & accurate in die cut mold replacement. Die mold less worn, Long lifetime in use. Also, Optional equipped with knife mold rotative mechanism, it makes the knife mold replaced convenient. Equipped with sticky mechanism, it can effectively clear dust/shavings after cutting. Optional equipped with Static eliminating device and board cleaner. Equipped with safety shelf and safety sensor on each size of machine in order to avoid any dangers while operation. Optional mechanisms: Rewind stacking system, Unwind system (shelf system or shelfless system).

High Precision Die Cutting Machine with CCD auto position system

Categories : Cutting Machines

Application:Optical film, Plastic film, e.g.: ITO, Diffuser, Reflects film, Brightness Enhancement Film (BEF), Soft PCB, Composite material. The material are not cracked while cutting. yicheen

Hydraulic Automatic Feed Die Cutting Machine (Four Column Press)

Categories : Cutting Machines

Application:Suitable for cutting one layer or several layer of such material as rubber sheet (bottom sole, medium sole), EVA, leather, plastic canvas, vacuum foaming products, nylons, carpet, mat, corks, soft tiles, paper boards and synthetic materials. yicheen The improved and upgraded traditional punching machines. Adopt four column of Hydraulic cylinder, average cutting force, high efficiency to raise the productivity. The upper die install by Magnetic platen, it is very convenient to change die. Microcomputer controller with touch sensing screen for maximum operation convenience and accuracy. Also, optional equipped with LCD screen computer control system is available, which it can memory operation program, provide the most convenient in operation and accurate cutting operation. Lubricated system design on Main shaft to avoid machine parts damage in movement and enhance machine lifetime. The Safety device (opening safe net for emergency stop motion) ensures the operator safety. Options: Air shaft unwind device, Air shaft rewind device

Extrusion Lamination Machines FML-EXL

Categories : Industrial Lamination

PLC STATION 1 - Laminating speed control - Extruding speed setting - Laminating parameter setting - Operation temperature setting - Driver status monitoring - Production additives saving - Malfunction warning information - Tension information monitoring PLC STATION 2 - Automatic unwind tension control - Diameter detecting control - Dancer roller tension control - Automatic cutting roll change - Jointing gluing surface check - Automatic pre-drive jointing - Automatic infeed tension control - E/P transducer control PLC STATION 3 - Automatic rewind tension control - Rewind tape tension control - Dancer roller tension control - Automatic cutting roll change - Non-stop roll change - Automatic length counting - Automatic outfeed tension control - E/P transducer control

Gravimetric Auto Dosing & Mixing System (ADMG)

Categories : Dosing and Measuring Equipment

COST SAVE: ADMG can measure powder resin, granule resin, master-batch, or additive precisely. EASY OPERATE: By entering the percentage of each batch and supply value to operate effectively, HMI automatically calculates all required values operate and monitor by single personnel or connect a PC through a modern to through a modern to maintain the system or solve problem. HMI is dynamic and versatile to provide the most efficient and economic operation. ACCURACY & CONSISTENCY: ADMG automatically measures the required amount accumulatively in order when you add extra resins or additives which will not affect the precision of dosing or mixing. ERROR REPORT: Error problems are recorded the time by day, month, and year for the maintenance. EASY CLEAN & SPACE SAVE: Stainless design and individual function units are easy to discharge and install.

Gravimetric Blenders - SGB

Categories : Dosing and Measuring Equipment

• Evenly mixing of materials after accurately weighing, control accuracy strictly of ±0.1~±0.3%. • Auto calibration after each material weighting ensures accuracy. • Up to 100 recipes can be stored for later use. • Alarm log function. • All parts detachable for easy cleaning. • For SGB-600 and models below, machine mount model is the standard supply (equipped with magnetic base,manual discharge valve), optional pneumatic slide gate is available also. • For SGB-2000 and models above, floor stand is the standard supply (equipped with moveable floor stand, storage hopper and pneumatic slide gate), optional SBU suction box is available also. • Has the function of recycled material compensation (recycling hopper is standardly equipped with low level switch). Aberration coompensation can be automatically calculated based to the feeding amount of recycled materials. • Memory card can be optional selected to store ratio information for product quality control. • Hopper low level sensor can be optional selected to send alarm when material is insufficent. • Optional analog signals (0~10V) output function for screw automatic adjusting of extrusion molding machine. • RS485 communication is optional to realize the centralized monitoring of connecting with molding machine. • Floor stand, pneumatic slide gate, storage bin and suction box should be optionally purchased for floor mounting. (Applicable for SGB-600 and models below)

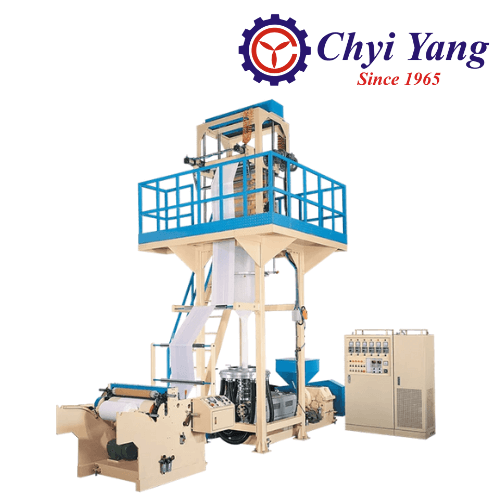

LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Double lip air ring & better cooling system to support the high speed capacity Can produce LDPE, LLDPE and shrinkable film Slitting device and double winder (up-and-down & back-to-back type) is offered to produce single layer film rolls. Optional Rotating die device is making uniform thickness film for printing & laminating purpose Optional Co-speed controller matches same speed for take-up unit and winder to avoid film to be stretched Purchasing HDPE die can produce HDPE film Fully automatic winder makes machine automatically & save time of operators We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Super High Speed HDPE/LDPE/LLDPE Blown Film Machine

Categories : Blown Film Extruders

Barrel and Screw have special treatment and forced feeding for better output Easy installation & operation Adjusting thickness easily by screws of die, high capacity & less plastic waste Automatic flying cutter & manual change reels winder, flying cutter to match the machine speed, won’t be re-winded on the nip roller Main Motor is driven by inverter for better performance & less electricity Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Hot Air Filling & Sealing Machine

Categories : Liquid Packaging Machines

●Monitor screen for easy operation. ●Imported hot air patent can make sealing fast and blazonry. ●Tubes orientation automatically. ●Cutting tail automatically after sealing. ●No sealing if no tube. ●Tube tail is durable after being sealed.