INSERT INJECTION MOLD

Categories : Injection Molds

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

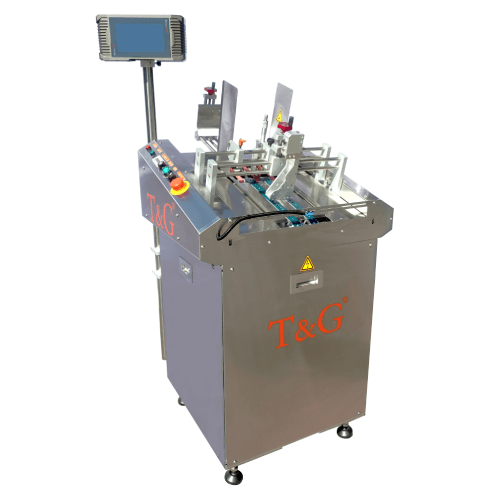

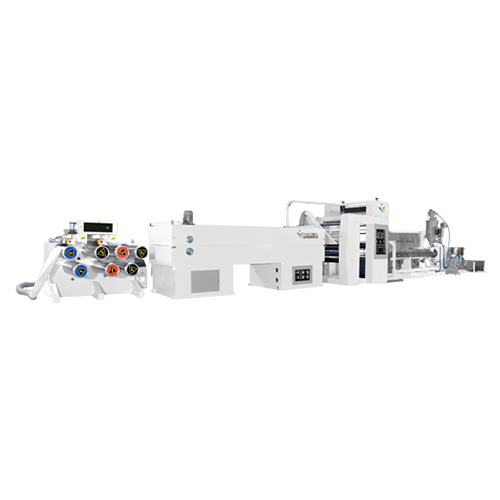

Automatic Feeding And Partitioning Machine AFC-700

Categories : Cutting Machines

Special feeder mechanism will not cause scrape or daamge to materials, to ensure 100% productivity of stisfactory products. Feed length and feed speed can be programmed to suit different properties of materials, so it has high flexibility in production. Simple and easy operation interface with touch-control monitor to expedite personnel training. Automatic recoiling mechanism, with the design of electronic control, to enable one-man one-machine operation. Feeder with servo control to ensure accurate feeding dimensions, and take precise control of material costs.

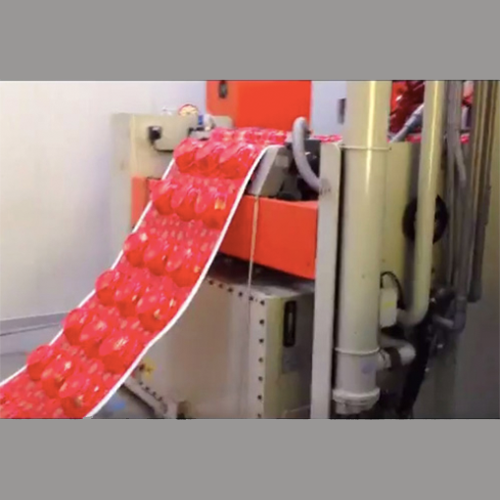

SL-The lightweight coating and laminator

Categories : Industrial Lamination

SL (The lightweight coating and laminator) The Solventless laminator provides an answer for the growing environmental concerns and protection measures. It also eliminates the possibility of solvent migration, making it preferred by food processing companies. If you are looking for environmentally friendly lightweight solution, this is the press for you to customize. KYMC

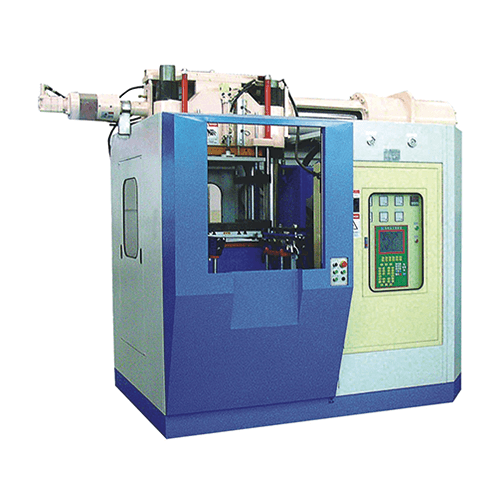

IMD Compression Molding

Categories : Rubber Injection Molding Machines

Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

Three-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

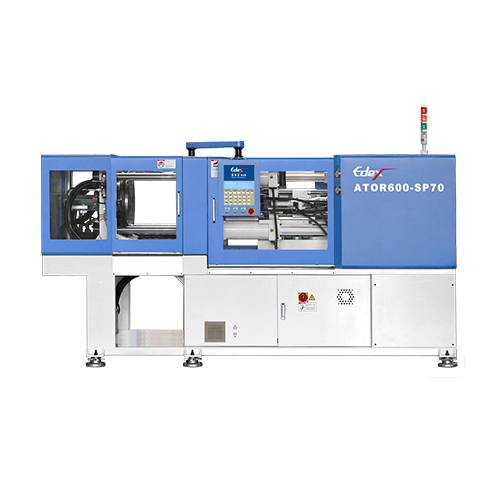

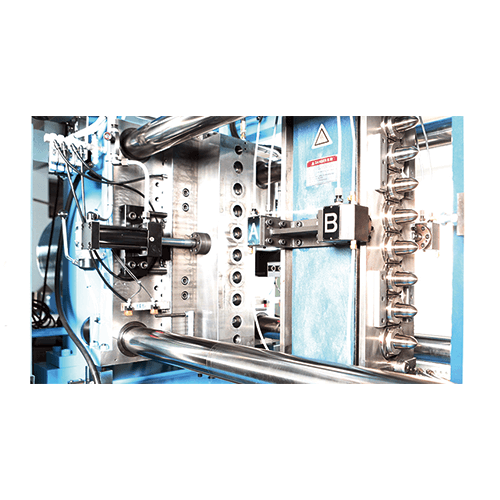

PET Stretch Blow Molding Machine - TEM06M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automaticalFEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.ly arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

GF/IB-Series Mould

Categories : Blow Molding Molds

●Common mold base design makes the best use of the resources. 1, 2 ,3-cavity or 1, 2, 5-cavity can share the same mold base. ●Interchangeable insert mold design simplifies the mold changeover and repair, keeps the maintenance cost low and prolongs the lifetime of the mold. ●Horizontal lock pins are highly durable, ensure precise mold parting line and enable easy mold opening and closing. (Pat. No. 92679) ●Valve gate hot runner system is designed with special anti-leaking device.

Cosmetic Bottle / Detergent Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

Corrugated knife

Categories : Industrial Knives

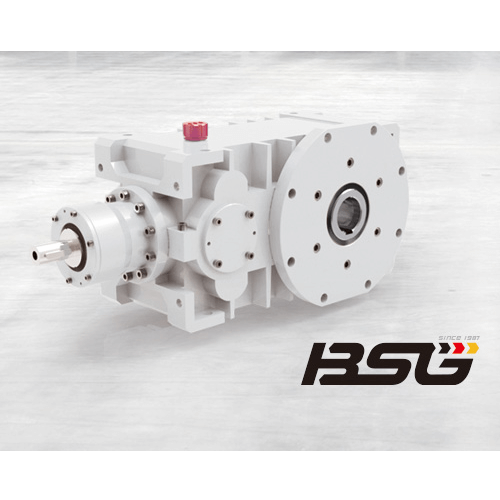

Right Angle Gearbox

Categories : Gears

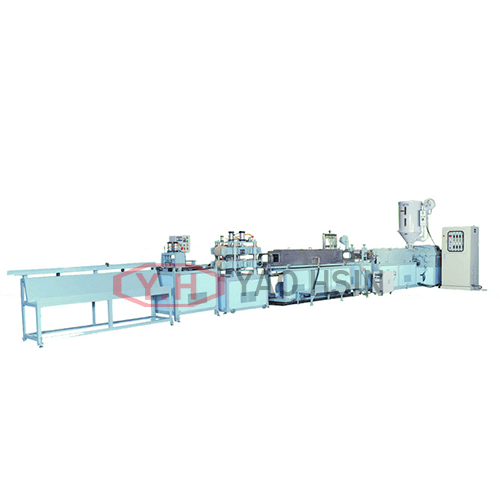

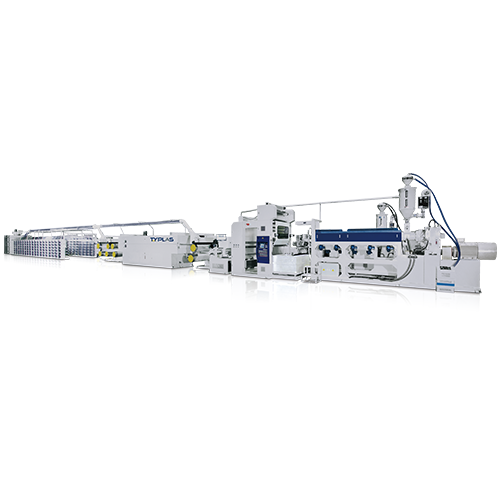

Three Layer PP Tape Line Making Machine-TY-TLTM Series

Categories : Extrusion Lines For Filaments and Yarn

TYPLAS’s TLTM series is mainly used in PP, HDPE tape line production, it used for weaving by circular loom and flat loom into tubular woven bags, onion bags, FIBC fabrics, tents, and waterproof tarpaulin.

PP/PS Rigid Sheet Recycle Machine

Categories : Plastic Waste Recycling Machines

To have PP/PS Rigid sheet wastage be recycled which can be used in industrial field and make it more friendly in this environment.

Spindle Servo Motor-SP3 Series

Categories : Motors

SP3 suitable for technical request below 12000RPM and available for customized or high speed type spindle motor.

Polyamid 6 - NA7200GK35

Categories : PA(Polyamide) /Nylon

Glass fiber 35% reinforced, high modulus, high impact, black colored. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

CONTRACT ASSEMBLY

Our Electronic Manufacturing Service (EMS) is used to Co- design, test, manufacture, distribute and provide repair services for electronic components and assemblies for Original Equipment Manufacturers. We have provided Co- design engineering and contract EMS for the consumer electronics, industrial, medical, military and telecommunications markets. We specialize in a variety of contract assembly levels from high volume, complex electro-mechanical assembly & testing to small volume, conceptual prototype runs. For small to medium device assembly, we utilize a cost savings system of mobile workstations and conveyors that can be quickly grouped into private and secure assembly cells. MANUFACTURING CAPABILITIES Electromechanical Assembly Subassembly and/or Final Product Assembly RoHS Compliant Assembly Lean Manufacturing PLM, MES, QMS, System Dedicated Program Management Functional and Post-Assembly Test Verification Material Procurement and Consigned Management FACILITIES 10,000 & 100,000 class clean rooms Flexible cell production system Mass management with Manufacturing Execution System (MES) 30,000 sq ft floor space with room for expansion Large, medium or small minimum order quantity (MOQ) HR expertise to maintain qualified production workers 24/7 operations SUPPLY CHAIN MANAGEMENT SERVICES YOMURA TECHNOLOGIES has many years of material & component sourcing experience and has direct relationships with factories around the world. Our office has been designed to coordinate quick quotes, provide constant updates and track all data needed to communicate with and expedite all client orders. This ensures a smooth transition from placement of orders to delivery. We understand our clients need to keep inventory levels low to control costs, yet still need to respond quickly for new orders to satisfy your customer demand. Clients can leverage our supply chain management expertise to receive volume quality products without high inventory risk. By customizing our stocking and logistics programs to meet your production needs we can reduce your material inventory during all stages of development from prototypes all the way through high volume production orders. TEST ENGINEERING Our Test Engineering department is staffed with experienced engineers and technicians who excel at working with customers to develop methodologies and design fixtures to reduce overall manufacturing costs, improve production yields, identify failures early, support root cause analysis, and assist design engineering with test analysis. Yomura has more than15 years waterproof IP68 test. REWORK SERVICES Sometimes rework of existing product assemblies is necessary to fix a design flaw, upgrade an assembly with a new components, or simply to find a cost down solution. Our rework specialists assure that resulting assemblies will meet the highest quality standards. CERTIFICATIONS QUALITY SYSTEM AS9100 / ISO 9001 / ISO 14001 / ISO 13485 / TS 16949 / UL Compliant / FDA / MFi

CE Certificate Rubber Injection Molding Machine

Categories : Rain boot Injection Molding Machines

Material supply system A special design of two-stage material supply is adopted. It expels bubbles out of the raw material in the most effective way and there is no dead material.

Flat Type Mask Making Machine

Categories : Bag Making Machine by Applications

3 or 4 layer flat type face mask making machine. Improved design from one-to-three synchronized setup to one-to-two synchronized setup, to reach optimum production rate of face masks, while reducing the overall machine price, and occupying less working area.

LDPE / LLDPE Blown Film Line(JC-LH Series)

Categories : Blown Film Extruders

JC-LH Series Blown Film Extrusion Line is designed for LDPE / LLDPE film production to achieve high output capacity with excellent film quality and transparency, fulfill the requirement for various applications. Application Material : LDPE / LLDPE Applciation Product : Agricultural Film / Shrink Film / Laundry Bag / Shopping Bag / Garment Bag Extrusion Ouptput : 120kg/hr.~380kg/hr.

ENS Series-Accumulator type

Categories : Automatic Blow Molding Machines

Accumulator type - Design for big size products, something like automotive parts, hospital bed, mobile toilet...etc. Taking out robot is optional.

Flat Yarn Making Machine For Jumbo Bag

Categories : Extrusion Lines For Filaments and Yarn

Function: It can produce flat knitting yarn with high tannin number. It can be used for knitting tonnage bags with high strength and low elongation, and provide the required number of ingots according to customer's demand.

Primary Packaging-General Filling-AF-80S

AF-80S liquid filling equipment common application is for above 60mL high viscosity liquid products such as shampoo, honey etc. The filling procedure applies piston filling method with pneumatic check valves and nozzles to minimize liquid leaking after filling procedure is completed.

S-03

Categories : Injection Molds

UNB Series-1300-1800

Categories : Industrial Robots

PET Stretch Blow Molding Machine - Economy Affordable New Choice (EX Series)

Categories : Automatic Blow Molding Machines

● Blower power consumption for 1000 bottles: 2Wh. ● Air Compressor power consumption for 1000 bottles: 6 kWh compact space. ● Screw driven controlled by servo motor providing fast and smooth motion. ● Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating. ● Low-pressure air compressor will NOT be required due to high-pressure recovery system. ● High efficient air recovery system up to 45%.

PVC Fiber Braided / Reinforce / Garden Hoses Extsuion Line

Categories : Extrusion Lines For Pipes and Profiles

Whole plant equipment includes extruder of inner pipe,cooling water tank,plastic wheel haul-off machine,wrapping yarn machine,oven,extruder of outer pipe,cooling water tank,blet type haul-off wheel,rooling machine,which are available for industry,agriculture and others.

Iron Powder Type Machine

Categories : Vertical Injection Molding Machines

Clamping pressure is stable and production efficiency is high.

WT - 240, 300, 360

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C Humidity Range: 40~80% Cooling Capacity: 56~105 KW