Ball Bearing

● 323B SERIES MONOFLOW ● 352B SERIES MONOFLOW ● 352C SERIES MONOFLOW ● 334 SERIES MONOFLOW 3.1/2” – 5”(B)

Vertical Clamping Horizontal Injection Four Columns Series YT SERIES

Categories : Vertical Injection Molding Machines

Vertical Clamping Horizontal Injection Four Columns Series - YT SERIES

Polyamid 66 - NB1200GH50

Categories : PA(Polyamide) /Nylon

Glass fiber 50% reinforced, low warpage, high modulus, high impact.

S-08

Categories : Injection Molds

SINGLE-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-1S 20-50)

Categories : Slitters and Rewinders

SRB-A-1S, one shaft type semi-automatic rewinding machine. It's a strongly stable machine for rewind aluminum foil & cling film. Which is friendly, easy-operate for a novice. SRB-A-1S is compatible for cling film and catering aluminum foil. It can solve the temporary requirement when you need to exchange materials. The mother roll available width is from 200-500 mm. The max rewinding speed is up to 500M/min. The finished product can be 1000M the longest. Machine uses electric speed adjustments. You can control the rewinding time more precisely, arrange manpower more effectively. SRB-A-1S multiple functions rewinding machine brings you better operation and higher efficacy. Welcome to consult machine with us. We will at your service.

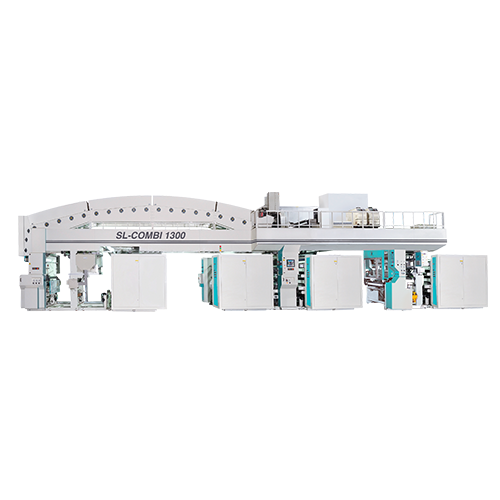

SL-COMBI-The multi-functional coating and laminator

Categories : Industrial Lamination

SL-COMBI ( The multi-functional coating and laminator) The SL-Combi is a versatile machine, combining a series of different coating and lamination techniques. Available for duplex or triplex lamination and up to muti-layer lamination inline with different coating or printing process. The machine could work with solvent, solventless and water based compounds. If you are looking for multi coating and laminating solution, this is the press for you to customize. KYMC

In-Mold Label

Categories : Films

In-Mold label (IML) is widely used in food container because the ink is between two layers of film and normally produce in dust-free fab or air conditioning clean room to minimize the human touch. Using IML can do the injection and labeling the product at the time. So it is suitable for mass production and standardization.

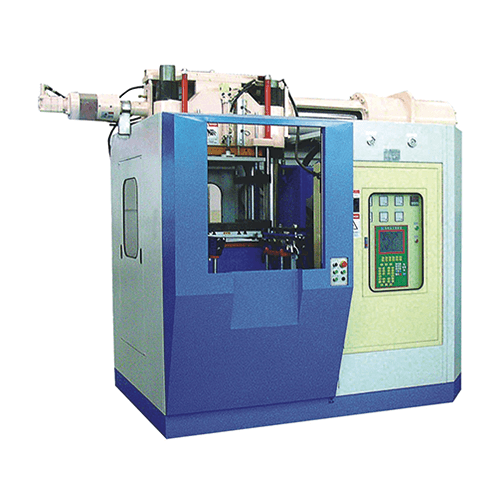

CE Certificate Rubber Injection Molding Machine

Categories : Rain boot Injection Molding Machines

Material supply system A special design of two-stage material supply is adopted. It expels bubbles out of the raw material in the most effective way and there is no dead material.

Inflex-The Flexographic press built for compatibility

Categories : Flexographic Printing Machines

Inflex ( The Flexographic press built for compatibility ) The Inflex printing machine can be placed in-line with any kind of converting equipment such as extruder, bag making, sheeter, die cutting…etc. If you are looking to add to your existing production line, this is the press for you to customize

LDPE-BLK-1

Categories : LDPE Resin

Color : Black ITEM SOURCE : industrial mixed color films PACKING : 25kg/bag

Promix Slabstock Machine

Categories : Foaming Machinery

A continuous foaming machine for producing flexible square polyurethane foam blocks.

Secondary Packaging - Cartoning - CJ-120

Categories : Cartoning Machines

The cartoning equipment applies the horizontal automatic production operation.

Block Boring Machine

Categories : Foaming Machinery

For boring the central hole of square or cylinder PU re-bonding foam blocks (density 50-100)

Polyamid 6 - NAE7200G30

Categories : PA(Polyamide) /Nylon

Glass fiber 30% reinforced, super high impact, black colored. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

WINDER

Categories : Slitters and Rewinders

Winder is installed on the calender production line or on the end of production line that carries out exchange or rewinding various materials, in response to different winding requirement according to the products. Our winder adopt precise guidance and easy to operate. The speed is up to 200 m / min, the reel diameter is up to 1500mm, width is up to 6000mm. Some models are capable of reeling the upper side of films into the inner or outer roller. And after cutting the film into the desired specification, up to 3 rollers from the single spindle can be done. Processing with the drive motor and control system, the maximum tension precision at high-speed is guaranteed. We have a broad selection of winders for different product layout or custom. Automatic center winder (taping or Free taping type), automatic single roller surface winder, multi-roller surface winder; auxiliary equipment (trimming cutter and central cutting device, roll unwinding equipment and weighing unit, automatic roller puller), etc.

THS 1300/1500/1800W

Categories : Industrial Robots

3Asix servo drive Pick up time :0.5sec,Cycle time:2.9 sec. Huge traverse chain ensure cable/tubing durability Motor thermal design long durable life Full colour touch screen controlle

Air Booster

Categories : Air Compressors

In order to higher the pneumatic air pressure necessary. Air Compressor

PA66 (Flame Retardant Grade)

Categories : PA(Polyamide) /Nylon

Increase the flame resistance of nylon at high temperatures.

ENS Series-Accumulator type

Categories : Automatic Blow Molding Machines

Accumulator type - Design for big size products, something like automotive parts, hospital bed, mobile toilet...etc. Taking out robot is optional.

YD Vertical Four-Column/Two-Color Rotary Table-Vertical Clamping and Vertical Injection Molding Machines

Categories : Vertical Injection Molding Machines

A. Standard double injection Vertical 4-columns direct-pressure clamping. In the upper mold plate, two separate vertical injection units is installed(separate injection hydraulic oil route) with the addition of round disc for this double injection machine. - Clamping force is 90- 500TON. Computerized and exclusively configured hydraulic system is used, which is more suitable for the production of general products( or special double-material) injection molding. - Two molds are installed on the upper mold plate while three lower molds are installed on the disc. When molding, the disc rotates alternatively at 120°to complete the two-color (two-material) injection molding or overmolding. - Highly efficient disc with water jacket device in the middle for cooling of the lower mold. - Expandable computer programs and special multistation disc (i.e. two upper molds and four lower molds). In the two lower modes, automated embedding and removing devices can be installed optionally to achieve automation of the whole machine work and increase production efficiency. B. Other double injection machine: - Type 1: A set of independent vertical “injection units” is added onto the upper mold plate of the original injection machine to form a double injection machine. Example: YH / YR / YC models + vertical injection. - Type 2: On the original injection machine, one or more sets of independent horizontal (level) injection units is combined to form a double injection machine. - Example: YH / YR models + horizontal injection - Type 3: The two-colors injection molding machine is combined to form a double injection machine by sharing a common disc. - Example: a. YH model + YT model + disc (2 ~ 4 stations) b. YH model + YH model + disc (2 ~ 4 stations)

Phoenix -The Entry Level Gearless Press

Categories : Flexographic Printing Machines

The compact class in flexo printing. The press is built for easy operation, affordability and is highly automated. Phoenix aims to help you remain competitive, given the market trends towards shorter runs and smaller packaging sizes. If you are looking for a compact gearless press, this is the press for you to customize. KYMC

Multi-Axle Auto Film Bonding Machine AFC-700LE

Categories : Cutting Machines

Patented Bonding Mechanism: In achieving higher bonding accuracy and without air bubbles. Fully Automatic Tension Control System: The tension of materials for each axle is controlled in an automatic way. Servo Transmission Control: Dual-Axle servomotor is used to achieve synchronized alignment control. Diversified Size Option: The parameter fine-tuning can be executed according to the characteristics of different materials. High Clean Bonding Environment: Which meet high-cleanliness bonding space requirements in providing higher Y-Rate. Unique Material Handling Techniques: Which is designed according to the characteristics of optical film to avoid scratching the material.

LIM、LSR (Liquid Silicon Rubber) Vertical Press (Rotary/Shuttle)

Categories : Silicone Injection Molding Machines

● Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. ● Increased productivity and efficiency with shuttle table or rotary table configuration. Pick and place products while another product finsihes molding.

Overload Protector

Categories : Mold Protection Devices

FUNCTION Overload Protector is equipped in Press machine to check hydraulic pressure of cylinder inside the slider. If happen overload, the hydraulic pressure of cylinder will be released immediately within 3/1000 seconds. When happen overload, in order to protect the press and die, the press will stop working immediately after receiving the signal from limit switch. After happen overload, the air will drive hydraulic pump to supply normal working pressure immediately and the press can work normal. It has pressure control valve inside of overload protector, which can adjust hydraulic pressure automatically and eliminate the impact of rising pressure (which cause by oil temperature rise) in pressing process. May select different types of components and control units base on the different types and specifications of press machines.

Hot plate heating type forming tools

Categories : Thermoforming Molds

Hot plate heating type forming molds is mainly for producing OPS products like containers, trays, and lids......etc. The post-treatment process is required for continuous trimming.

Atom- Horizontal Plunger Type Micro Injection Molding Machine

Categories : Horizontal Injection Molding Machines

● The best choice in micro injection products. ● New design patent-IPIS (Interchangeable Plunger Injection System). ● Plunger Type Injection can highly save runner resin. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Intelligent program controller makes injection easier. ● The shortest injection molding machine, the length of Atom100 only 1.9 meters. ● Precise energy-saving hydraulic system.

Primary Packaging–General - Closing - AC-80

Categories : Capping Machines

The container cap closing processor is capable to be applied for both plastic screw caps and ROPP sealing caps in one machine by changing capping system components.

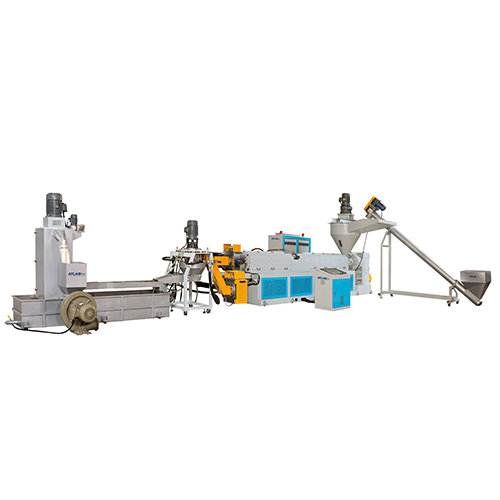

HOPPER FEEDING & DIE FACE CUTTING PLASTIC RECYCLING & PELLETIZING MACHINE

Categories : Plastic Pelletizer Machines

Suitable for shredded fragments from rigid plastics and injection materials

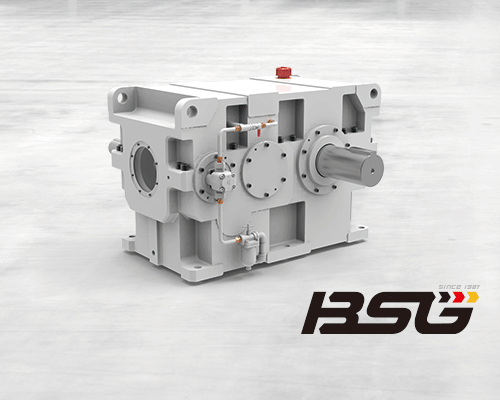

75 Liter Hollow Shaft Gearbox

Categories : Gears

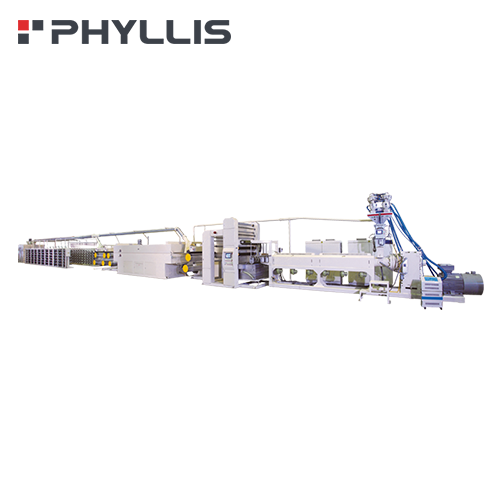

Extrusion Tape Line (FIBC Tapes)

Categories : Tape Extrusion Machines

One layer extrusion tape line specially designed to produce PP tapes for high performance application at premium quality mainly used for FIBC fabrics, and various technical applications.

DG-P Series Special-Purpose Pet Injection Molding Machine

Categories : Automatic Injection Molding Machine

Recently, PET material is used greatly on producing containers, and gradually substitutes PP, PE, PVC material. Due to the characteristic of PET, the screw design is different from general. Besides, during producing mold, when the alternation of coldness and heat, the mold surface will be liable to congeal to mist when it touch with air. This affects its process of crystallization largely. Therefore, it is significant to maintain the temperature stable at clamping side; and DG-P series injection molding machine is particular to PET material producing.

Vertical Plastic and Injection Molding Machine YHL SERIES

Categories : Vertical Injection Molding Machines

- Vertical upright clamping, straight shot structure, simple structure. - The design method of shooting the center shifting element makes the three-sided space more open, and can be applied to the long strip-shaped automobile sealing strip to form a corner or to form a lead product, which makes the forming work easier. - Vertical plastic injection machine, injection system adopts standard and modular design, universal injection molding of various types of inserts, and excellent plastic molding ability. - Vertical rubber injection machine, injection system adopts screw feeding and plunger injection two-stage design, which can adapt to different hardness rubber materials, and rubber injection is stable and accurate. - Optimized design, such as one of the most reliable injection molding equipment for clamping/injection/plasticizing.

Mold Changer System

Categories : Mold Changing Systems

FEATURES Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival and positioning in the process of mold mov-in. Device for preventing mold sliding.