Classification : Vertical Clamping Horizontal Injection

Country: Taiwan

Phone: 886-2-26946450

Fax: 886-2-26946454

Contact Person: Nina Tsai

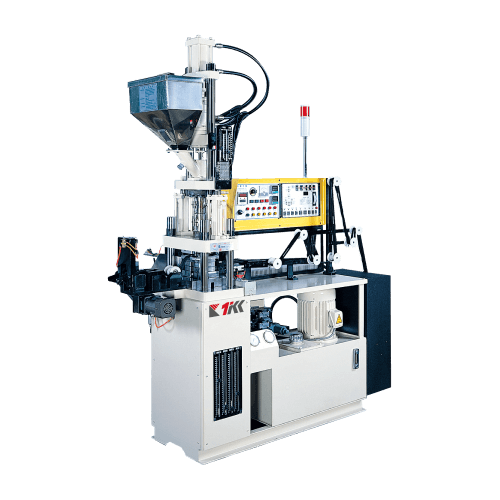

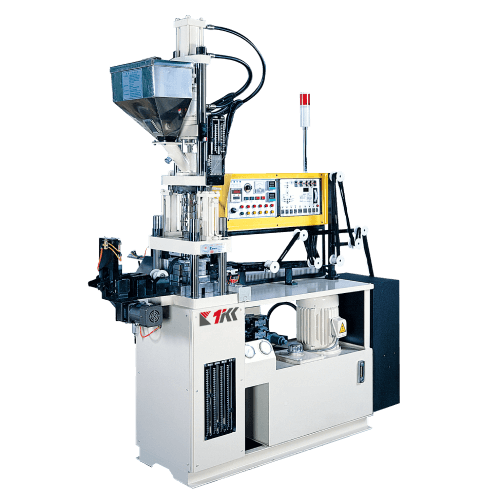

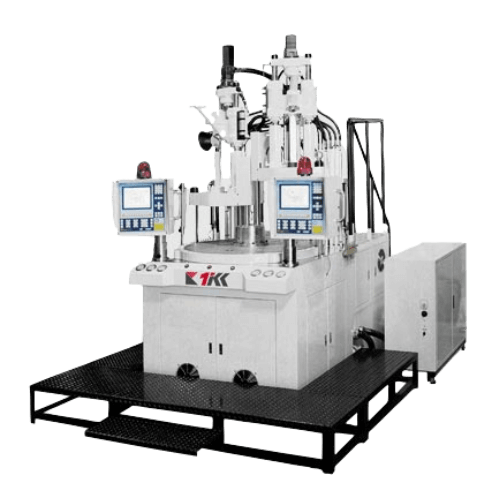

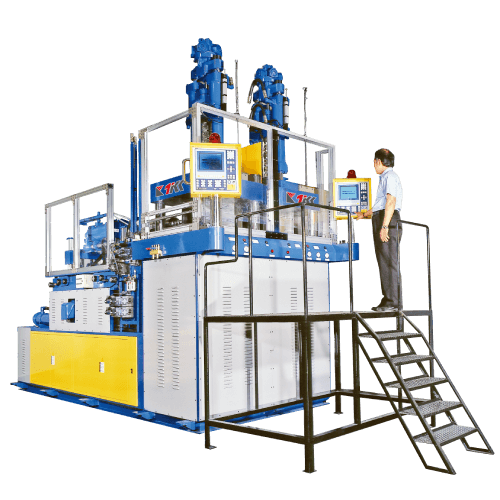

YT Series

- Fixed mold (V) and the two sliding mold (2S) adopts four-column vertical pressure clamping for horizontal injection. Strong mechanical structure allows greater endurance for clamping force up to 500 ~ 800TON.

- Standard disc is vertical 3-column vertical pressure clamping. The two station design is for horizontal injection.

- With special needs, 4-columns vertical pressure clamping is available with the disc mold stations at 3 to 4.

- The nozzle can be adjusted in height level, easily for center level correction of mold feed into make mold design more convenient.

- Injection is smooth and powerful, suitable for forming larger fitting pieces. With a special L / D aspect ratio of the injection screw, it is more suitable for engineering plastics.

- Scalable computer programs, automatically removing, embedded devices, and other connections allow fully automatic operation of the whole machine.

- ─Two sliding molds (2S) ─ (alternating dual sliding molds): One mold is in injection molding and the other is outside for removing and placing mosaic pieces. Operation safety and production efficiency is high.

- ─Round disc (R) ─ alternatively rotating back and forth at 180 ° horizontally to allow users to operate in a fixed plane for retrieval and inserting pieces. This makes the work more convenient.

| Model | YT-60 | YT-90 | YT-120 | YT-160 | YT-200 | YT-250 | YT-350 | ||||||||||||||

| V | 2S | 3R | V | 2S | 3R | V | 2S | 3R | V | 2S | 3R | V | 2S | 3R | V | 2S | 3R | V | 2S | 3R | |

| INJECTION UNIT | |||||||||||||||||||||

|

Screw Diameter

(mm)

|

32 & 40 | 34 & 42 | 38 & 50 | 42 & 55 | 46 & 60 | 55 & 65 | 60 & 70 | ||||||||||||||

|

Injection Pressure

(kgf / cm2)

|

1914 & 1225 | 1931 & 1256 | 2079 & 1200 | 2000 & 1161 | 2034 & 1195 | 2082 & 1491 | 1749 & 1285 | ||||||||||||||

|

Injection Capacity

(cm3)

|

124 & 194 | 149 & 228 | 204 & 353 | 276 & 474 | 365 & 621 | 593 & 829 | 706 & 961 | ||||||||||||||

|

Max. Injection Weight

(gr)

|

112 & 175 | 134 & 205 | 183 & 317 | 249 & 427 | 328 & 559 | 534 & 742 | 630 & 860 | ||||||||||||||

|

Max. Injection Weight

(oz)

|

3.9 & 6.1 | 4.7 & 7.2 | 6.4 & 11.1 | 8.7 & 15 | 11.5 & 19.7 | 18.8 & 26.2 | 22.1 & 30.2 | ||||||||||||||

|

Injection Rate

(cm3 / sec)

|

56 & 88 | 70 & 108 | 81 & 141 | 109 & 187 | 128 & 217 | 169 & 236 | 227 & 310 | ||||||||||||||

| CLAMPING UNIT | |||||||||||||||||||||

|

Clamping Force

(tf)

|

60 | 90 | 120 | 160 | 200 | 250 | 350 | ||||||||||||||

|

Clamping Stroke

(mm)

|

250 | 250 | 300 | 300 | 350 | 400 | 450 | ||||||||||||||

|

Max. Open Distance

(mm)

|

450 | 450 | 550 | 550 | 650 | 700 | 850 | ||||||||||||||

|

Min. Mold Height

(mm)

|

200 | 200 | 250 | 250 | 300 | 300 | 400 | ||||||||||||||

|

Dimension of Tie Bar

(mm)

|

390 × 390 | 440 × 440 | 490 × 490 | 580 × 580 | 640 × 640 | 740 × 740 | 840 × 840 | ||||||||||||||

|

Hydraulic Ejector Force

(tf)

|

1.7 | 2.7 | 3.5 | 4.3 | 4.3 | 5.3 | 7 | ||||||||||||||

|

Ejector Stroke

(mm)

|

100 | 100 | 125 | 125 | 125 | 150 | 150 | ||||||||||||||

|

Nozzle Center Height

(mm)

|

130 ± 20 | 130 ± 20 | 150 ± 25 | 150 ± 25 | 175 ± 25 | 175 ± 25 | 175 ± 25 | ||||||||||||||

|

From The Mold Center to The Nozzle

(mm)

|

min 125 | min 125 | min 125 | min 150 | min 200 | min 200 | min 250 | ||||||||||||||

| SLIDE (2S) | |||||||||||||||||||||

|

Slide Stroke

(mm)

|

460 | 520 | 580 | 650 | 750 | 870 | 970 | ||||||||||||||

|

Slide Dimension

(mm)

|

840 × 380 | 940 × 420 | 1060 × 480 | 1190 × 540 | 1380 × 630 | 1600 × 730 | 1800 × 830 | ||||||||||||||

| ROTARY UNIT (VR) | |||||||||||||||||||||

|

Rotary Diameter

(mm)

|

Φ 856 | Φ 980 | Φ 1172 | Φ 1350 | Φ 1550 | Φ 1750 | Φ 1750 | ||||||||||||||

| OTHER | |||||||||||||||||||||

|

Drive Motor

(kw)

|

7.5 (10) | 7.5+2.2 (10+3) | 11.2 (15) | 11.2+2.2 (15+3) | 14.9 (20) | 14.9+2.2 (20+3) | 18.7 (25) | 18.7+2.2 (25+3) | 22.4 (30) | 22.4+2.2 (30+3) | 29.8 (40) | 29.8+2.2 (40+3) | 39.3 (50) | 39.3+2.2 (50+3) | |||||||

|

Heater

(kw)

|

6 | 7.5 | 9 | 11.5 | 13.5 | 16 | 19 | ||||||||||||||

|

Oil Tank Capacity

(L)

|

250 | 300 | 350 | 400 | 450 | 500 | 600 | ||||||||||||||

| Dimension of Machine : L | 3.2 | 3.2 | 3.5 | 3.7 | 3.7 | 4.1 | 4.1 | 4.1 | 4.5 | 4.5 | 4.5 | 4.9 | 4.9 | 4.9 | 5.3 | 5.3 | 5.5 | 5.8 | 5.3 | 5.5 | 5.8 |

| Dimension of Machine : W | 1.1 | 1.6 | 1.2 | 1.2 | 1.9 | 1.3 | 1.3 | 2.1 | 1.5 | 1.4 | 2.3 | 1.7 | 1.5 | 2.6 | 1.9 | 1.7 | 2.8 | 2.3 | 1.7 | 2.8 | 2.3 |

| Dimension of Machine : H | 3 | 3.2 | 3.3 | 3.1 | 3.3 | 3.4 | 3.3 | 3.5 | 3.6 | 3.5 | 3.7 | 3.8 | 3.7 | 3.9 | 4 | 4.1 | 4.2 | 4.3 | 4.1 | 4.2 | 4.3 |

|

Weight of Machine

(T)

|

4.9 | 6 | 7.5 | 7 | 8 | 9.5 | 8.5 | 10 | 12 | 10 | 11.5 | 13 | 12 | 14 | 16 | 16 | 17 | 19 | 17 | 19 | 21 |