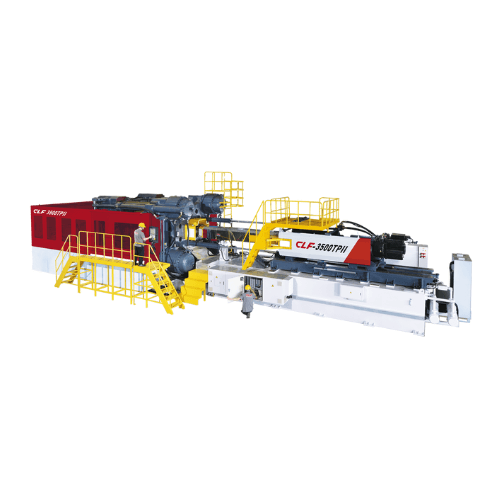

Two Platen Plastic Injection Molding Machine - TPII SERIES

Categories : Injection Molding Machines by Platen

Unique two platen design for clamping mechanism exhibits exceptionally high speed clamping feature.

Plastic Injection Molding Machine - TX Series

Categories : Toggle Clamping Injection Molding Machines

A performance-proven plastic injection molding machine with a faster injection speed

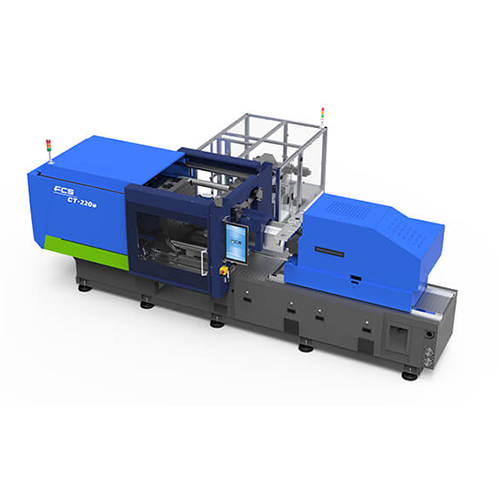

Advanced Servo Hydraulic Injection Molding Machine (FA Series)

Categories : Hydraulic Clamping Injection Molding Machines

Advanced Servo Hydraulic Injection Molding Machine (FA Series) It is a newly released model of advanced toggle hydraulic and servo energy-saving IMM by FCS. The applicable industries include houseware, stationary, automotive, 3C and home appliance industries, especially for multi function printers, laptop or computer parts.

Outward Toggle Type Plastic Injection Molding Machine - TWII-Series

Categories : Toggle Clamping Injection Molding Machines

Outward Toggle Clamping a Significant Increase in Structural Accuracy of Mold Platen Benefit: High Rigidity / Highly Precise Injection, Energy Saving / Customization Plasticized Applications: Preform Bottle Cap, Paint Bucket

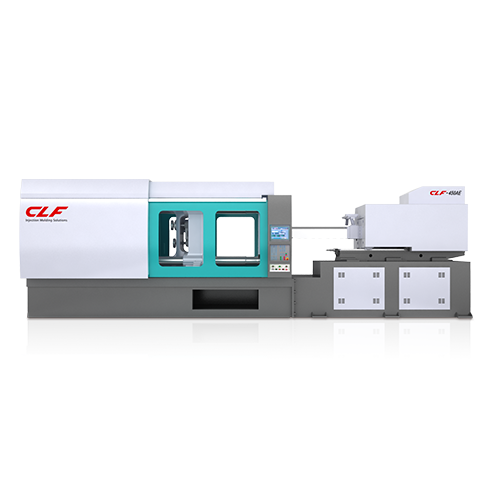

All Electric Plastic Injection Molding Machine - AE Series

Categories : Electrical Injection Molding Machines

Based on years of OEM/ODM cooperation experience with a renowned Japanese company, CLF has accumulated extensive expertise in this field of technology...

Special Purpose Machine KVV+VV-3R / Hose

Categories : Vertical Injection Molding Machines

The ultimate vertical injection molding solution for efficient injection of large work pieces. With a vertical mold clamp and horizontal injection, it offers a long closing and opening stroke.

KT Series Injection Molding Machine (SINGLE SLIDE)

Categories : Vertical Injection Molding Machines

Vertical mold clamping and injection, small footprint and high degree of precision.....

KC-DM (DOUBLE SLIDE)

Categories : Slippers Making Machines

KC Series Vertical Injection Molding Machine

In Mold Labeling Turnkey Solution

Categories : In Mold Labeling Injection Molding Machines

In Mold Labeling (IML) is a high-efficient technique. By placing the printed label in the mold before injection and bonding the label with the plastic products during injection process, lML can produce high-quality products efficiently, cost-effectively and also environmentally friendly.

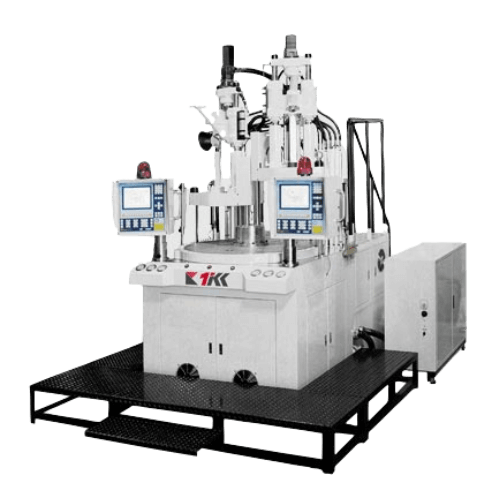

KC Series Vertical Injection Molding Machine (ROTARY TABLE)

Categories : Slippers Making Machines

Vertical mold clamp and horizontal injection. No-post design is open on three sides and suitable for medium-size injected products with inclusions.....

KC Series Vertical Injection Molding Machine (STANDARD)

Categories : Vertical Injection Molding Machines

Vertical mold clamp and horizontal injection. No-post design is open on three sides and suitable for medium-size injected products with inclusions.....

iMF4.0 Intelligent ManuFactory

Categories : Industrial Software

Injection molding machines are used in various industries. In order to support the customers to approach smart production, FCS developed and launched the Industry 4.0 solution for injection molding since 2017, which is “iMF 4.0 Intelligent ManuFactory System”. iMF 4.0 can be mounted on the injection molding machines and can independently adjust and control quality parameters based on the surrounding information. It uses intelligent sensing modules to improve product yield and reduce production waste. Through engineering monitoring and feedback suggestions, it can achieve advanced warning and avoid accidental shutdown losses, thus seizing the "intelligent" manufacturing opportunities for customers. The iMF 4.0 system is based on the cycle time management and integrates the concept of mold management, machine management and material management, and OPC international communication protocol to achieve instant display of overall equipment efficiency information and abnormal message statistics. It can be used regardless of the brand of the injection machine, so that the production manager can promptly grasp the production status and rapidly achieve the purpose of abnormal production countermeasures.