PET Stretch Blow Molding Machine - TEM06S2

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Stretch Blow Molding Machine - TEM04M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

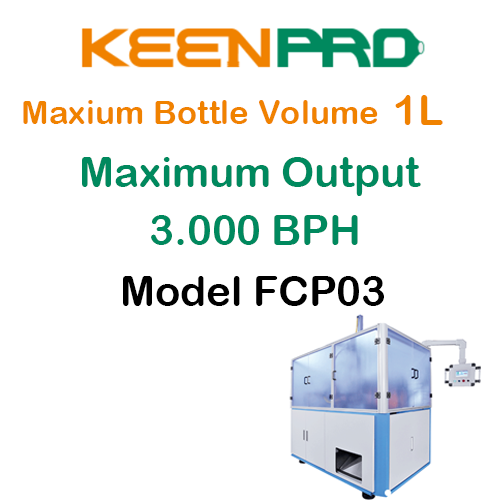

PET Blow Molding Machine - FCP03

Categories : Horizontal Blow Molding Machines

● Grouping Brand ● Parts Internationalization ● Apply for Small Production Line ● Complete Online Consultation Service ● QR code Intelligent Management ● Networkable Machine (Optional)

PET Stretch Blow Molding Machine - TEM08S2-88

Categories : Automatic Blow Molding Machines

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Wire / Plug Machine Y-V SERIES

Categories : Vertical Injection Molding Machines

- Vertical clamping / vertical injection, suitable for general electrical plugs, electronic components and other small insert molding. - Two or three stage temperature control / injection speed / non-stage adjustment of back pressure, etc., more suitable for parts molding of precision plastic. - Quick mold locking / low pressure low speed to mold lock, a special safety design to protect the mold. - Lower mold fixing/upper mold movable; with fine positioning for molding piece in mold. The device is equipped with hydraulic ejector for easy removal of the product. - Electric-control fittings / hydraulic fittings using domestic brands in precision, durability and low noise. The Clamping force is 15-25TON with PLC programming electric-control computer in single- comparison- pressure control or computer in full ratio (compare voltage; compare current); there are three options available to customers. - A single sliding mold 1S and two sliding mold 2S can be added, enabling the operation to be more efficient and safer in production.

Low Pressure Injection Molding Machine

Categories : Low Pressure Injection Molding Machines

Our LPM Low Pressure Molding Machine, CE marking certified, with its very low injection pressure 20~500psi (1.5~35 BAR) into the mold cavity and electronic parts to be encapsulated. Hot-melt Polyamide starts cooling down when it touches the cavity, then apply continuous injection pressure. The over-molding process will not harm any fragile solder joint of the circuit board (PCB Overmolding). At first, it's uses to replace toxic and bulky conventional potting processes, gradually spread to the world in market such as automotive market, medical, military, domestic appliance market.

Rotary Table Low Pressure Molding Machine

Categories : Horizontal Injection Molding Machines

Low pressure molding production is a process uses hot liquidify Polyamide material. Wire harnesses, connectors, sensors, micro switches, etc. These Automotive Electronics need to be waterproof and durable. rapid production, environmental protection, reduce the defect rates and better outlook design, the application of low-pressure injection machines in this automotive industry has gradually increased.

Liquid Silicone Rubber Injection Molding Machine

Categories : Rain boot Injection Molding Machines

Applicable for the production of vehicle parts, electronic and medical goods, infant care and food products etc. Save time for production process and increase productivity. The best solution to support quality and efficiency. oxygen mask

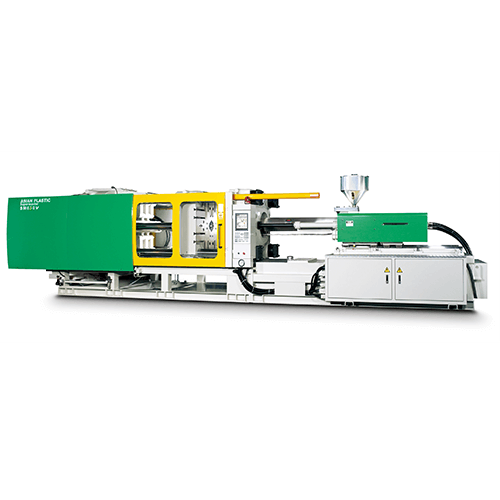

Heavy Duty Double Toggle Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision. The injection carriage uses a balanced double hydraulic cylinder to provide a secure hold between the mould and the nozzle to eliminate nozzle leakage. Linear guide ways reduce mechanical friction, decrease machine wear and increases accuracy over back pressure providing better control of the injection sequence. Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportional valves is more precise resulting in more accurate control.

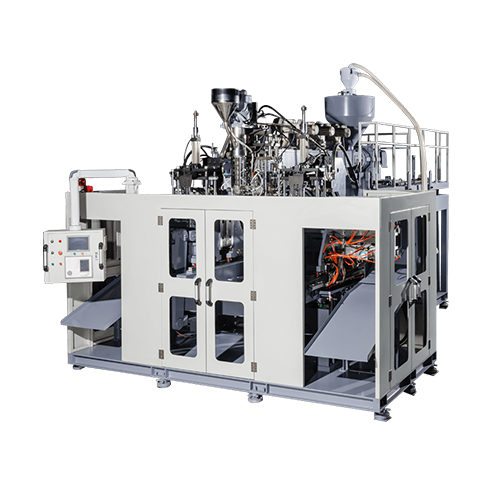

Medium Blow Molding Machine - Double Station

Categories : Electric Blow Molding Machines

Medium-Continuous Type Blow Molding Machine An all-rounder that is ideal for a variety of applications. Medium blow molding machines are used to produce medium-sized products but can also be adapted for small or large-scale productions. Products that are commonly manufactured by medium continuous blow molding machines include: 20/25L jerry cans 10/20L inner thread jerry cans Diamond-shaped jerry cans Round jerry cans Water tanks With applications for edible oil, lubrication oil, electronic, agriculture, and chemical liquids, this jerry can making machine is also available as a single or double station machine, for multi-layers, multi-cavities, or even multi-color productions.

Precision Four-Column Plan Hydraulic Cutting Machine-CSS-202B

Categories : Foaming Machinery

●The body of the machine is made of special steel and has gone through rigorous processing that shows a ram pressure-resistant function and precision. ●Up and down stroke applies steel pole as the rail that brings out an effect of high precision and shaking-resistant characteristic. ●A design of Two-pod oil cylinder shows the stable force and large torsion.

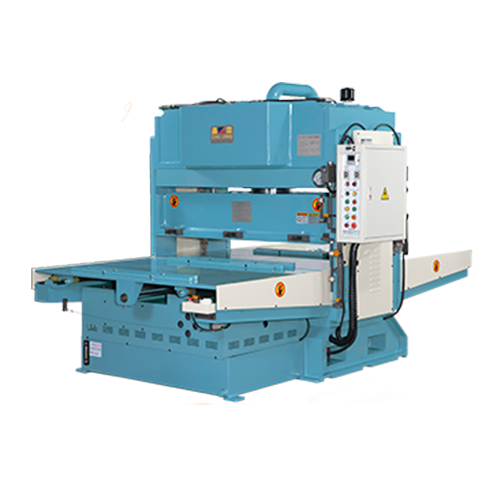

Precision Hydraulic Double-Sided Auto Feed Cutter CSS-806

Categories : Foaming Machinery

Both double-side and single-side operation, time and manpower saving, one machine for two purposes to give excellent effect of production. Double-side pressure and touch-type electronic counter watch are separatively deviced, so different sizes of product can be adopted. Super precision oil way design, silent for performance, stable location for each action, to increase the service life of parts and tool mold deviced with cutting board rotary table, the consumption of cutting board can de reduced. Body frame adopts high tension steel plate under stress relief process for long application without being deformed.(We welcome any special size from buyer).