42 Inch Tire Curing Press

Categories : Rubber Curing/Vulcanizing Machines

•The mainframe consists of the steel plate and U type steel welding with high-temperature treatment. After matching, release stress to improve the machine life cycle. • Return oil with filter and cooler to maintain the stable hydraulic system. • Excellent solid frame mechanism design with FEA approval to enhance body strength.

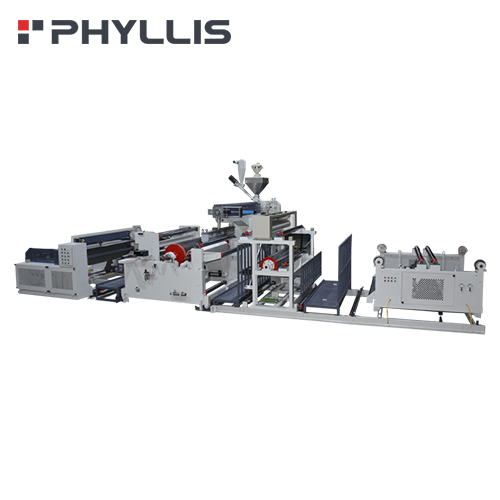

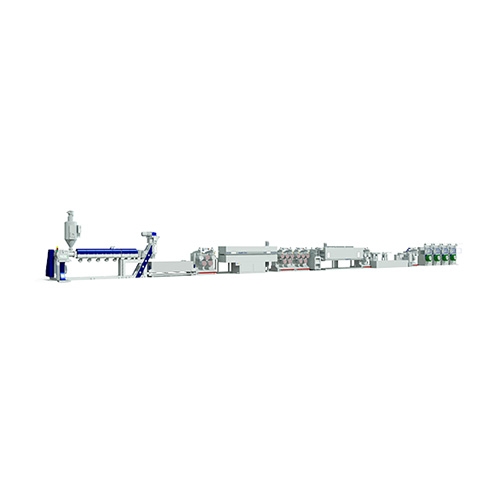

Lamination Line (Woven Sack)

Categories : Extrusion Lamination Machines

Lamination application for tubular woven fabrics. High level of coating technique provides smooth and even coating surface, which reduces material waste, while maintaining highest quality of coated fabric.

PP Strapping Band Extrusion Line (JC-SPP Series)

Categories : Tape Extrusion Machines

The JC-SPP series PP Strapping Band Extrusion Line designed for making PP polypropylene straps, commonly used for light to medium load packaging such as newspaper & magazine, carton boxes, pallets, and other industrial and consumer usages.

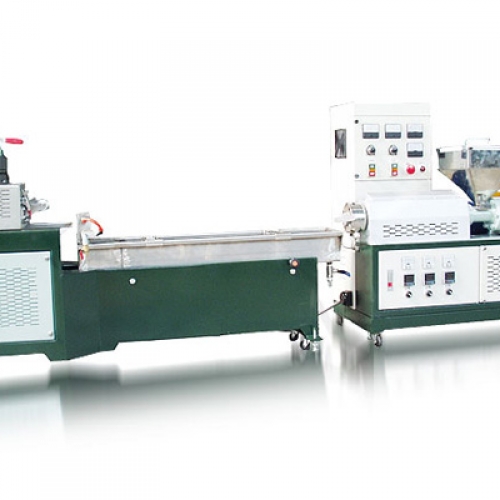

Dyeing and Pelletizing Plant Color Testing

Categories : Plastic Pelletizer Machines

• Model: TY-DB Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS. • Specific resin: PC, PET, ACRYLIC, NYLON. • Capacity: 3-10 kg/hr

PC / ABS Alloy - CA6421B

Categories : Alloys

General purpose. Application: Electronic, Electrical cases, Thin-wall application, Automotive parts.

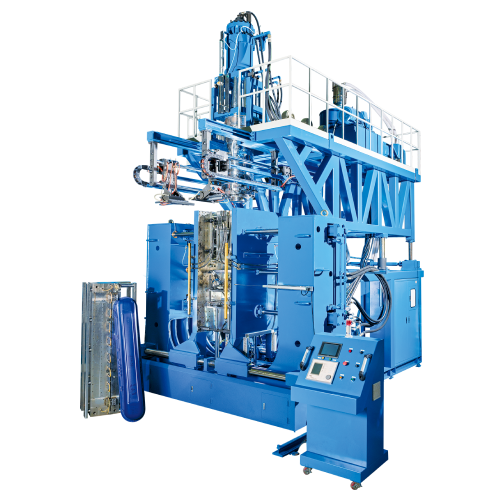

Large Blow Molding Machine

Categories : Horizontal Blow Molding Machines

Large –Accumulator Die Head Type Blow Molding Machine These series models are suitable for productions ranging from 30L up to 130L whether for barrels, pallets, toys, water storage tanks, floats, automobile parts, and narrow or full open mouth drums applications. This machine is suitable for blowing irregular-shaped plastic products. Applications of a large accumulator blow molding machine include the following: Barrels 2-mouth jerry cans Toys Water storage tanks/ PC water jugs Paddle wheel aerator floats Air duct and other automobile parts Baby safety seats Cooler box/ice bucket Sports equipment Narrow mouth and full open mouth drums For certain products, we have developed a high-speed model of this series for customers that need a high production output.

PVC Fiber Braided / Reinforce / Garden Hoses Extsuion Line

Categories : Extrusion Lines For Pipes and Profiles

Whole plant equipment includes extruder of inner pipe,cooling water tank,plastic wheel haul-off machine,wrapping yarn machine,oven,extruder of outer pipe,cooling water tank,blet type haul-off wheel,rooling machine,which are available for industry,agriculture and others.

PET Strapping Band Extrusion Line (JC-SPET Series)

Categories : Tape Extrusion Machines

Our JC-SPET Series of strapping band extrusion lines utilize the latest extrusion technology to produce PET strapping bands from 100% treated PET bottle flakes. The resulting straps possess tensile and breaking strength comparable with steel bands, offering a safer, economical, environmentally-friendly solution for medium- to heavy-duty applications, such as securing bricks, tile, cotton bales, and lumber.

PET Preform Injection Molding Machine Servo - 120PET to Servo 470PET

Categories : Horizontal Injection Molding Machines

Standard L/D ratio of 24 times and above for good plasticizing quality. Application of barrier type screw features and an extra barrier ridge to ensure homogenous plasticization when melting PET. Because of the viscosity of the PET, the screw speed and capacity of the hydraulic motor is upgraded to achieve higher plasticization. Compatible with auxiliaries such as PET preform molds, material dryer, mold sweat dehumidifier, water chiller, conveyor and post-cooling automation. Optional features such as a shut-off nozzle or an ejector on the fly are available. These are for shortening the total cycle time and maximizing the output.

PET Sretch Blow Molding Machine - TEM04S2-88

Categories : Automatic Blow Molding Machines

PET STRETCH BLOW MOLDING MACHINE-TEM04S2-88 FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Stretch Blow Molding Machine - TEM06M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automaticalFEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.ly arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET Stretch Blow Molding Machine - TEM04M1

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.