Classification : Products

Country: Taiwan

Phone: 886-6-2330519

Fax: 886-6-2330398

Contact Person: Joseph Lung

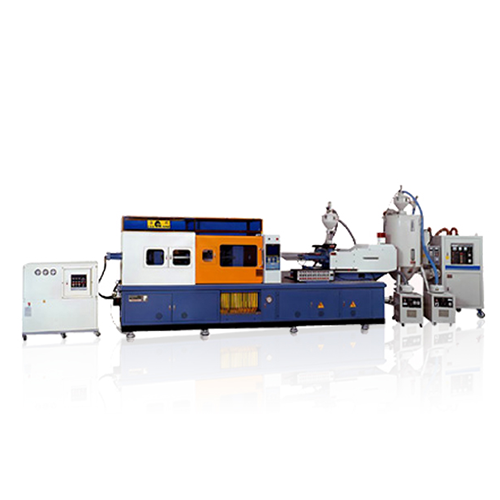

SPECIFIC TECHNICAL REVISES FOR PET PREFORM PRODUCTION

- Standard L/D ratio of 24 times and above for good plasticizing quality. Application of barrier type screw features and an extra barrier ridge to ensure homogenous plasticization when melting PET.

- Because of the viscosity of the PET, the screw speed and capacity of the hydraulic motor is upgraded to achieve higher plasticization.

- Compatible with auxiliaries such as PET preform molds, material dryer, mold sweat dehumidifier, water chiller, conveyor and post-cooling automation.

- Optional features such as a shut-off nozzle or an ejector on the fly are available. These are for shortening the total cycle time and maximizing the output.

| Model | International Size | Theoretical Injection Volume | Clamping Force | Space Between Tie Bars | Mold Opening Stroke |

| Servo 120PET | 1200H-614 | 452 | 120 | 395x395 | 380 |

| Servo 150PET | 1500H-614 | 452 | 150 | 425x425 | 430 |

| Servo 190PET | 1900H-958 | 763 | 190 | 470x470 | 480 |

| Servo 230PET | 2300H-958 | 763 | 230 | 515x515 | 525 |

| Servo 270PET | 2700H-1703 | 1232 | 270 | 555x555 | 570 |

| Servo 320PET | 3200H-1703 | 1232 | 320 | 620x620 | 620 |

| Servo 370PET | 3700H-2045 | 1709 | 370 | 700x650 | 670 |

| Servo 470PET | 4700H-2862 | 2156 | 470 | 770x742 | 770 |