Zipper Bag Making Machine

Categories : Plastic Bag Making Machines

World Steel is a manufacturer of Zip Lock Bag Making Machines. The machines use the latest technology offering advanced performance and versatility that facilitate easy installation, setup, operation and maintenance. These machines are ideal for producing high quality ziplock bags at an excellent cost efficiency. EFFICIENT ZIP LOCK BAG MAKING MACHINE:HIGH CAPACITY AT 120 BAG/MIN The Automatic Zipper Bag Machine converts a tubular roll of pp material with clip chain structure into a side seal bag, no need to purchase additional zippers. The machine is capable of running at 120 bags / minute. This saves cost, space and labor. AUTOMATIC ZIPPER BAG MACHINE FOR PP FILM Our Automatic Zipper Bag Making Machine can be used for producing a high quality side sealed zipper bag from PP materials.

Extrusion Tape Line (Three Layer Tapes)

Categories : Tape Extrusion Machines

Three layer extrusion tape line with break-through technology to produce 3 layer PP tapes at premium quality and lowest manufacturing costs. The tapes are mainly used for PP woven sack, and various applications. PP/HDPE Flat Yarn Extrusion Line (For PP/HDPE Woven Fabrics)

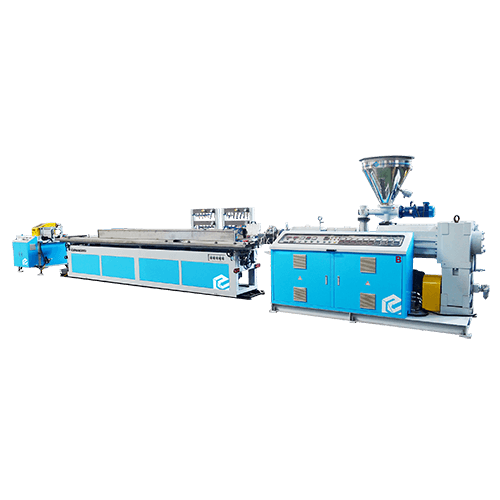

WPC extrusion machine line

Categories : Extrusion Lines For Pipes and Profiles

The circular economy is a topic of global concern, and Everplast has been committed to this. Among them, WPC can effectively use recycled PE/PP plastics and natural fibers to manufacture imitation wood products through the WPC extrusion production line. This WPC product is also widely used in outdoor building materials today. The new properties of Everplast plastic wood composites (WPC), such as PP/PE resin mixed with 40-80% natural fibers or PVC mixed with 40-70% natural fibers, produce different types of WPC profiles. According to the plastic base material, WPC is mainly divided into PVC, PE, PP, PS, and ABS plastic bases. Among them, PVC/PE/PP plastic wood could be more popular in the market, has a woody feel, and can standard high temperatures. The appearance and texture are very similar to real wood.

OPP/BOPP Labeling Machine For Square & Round Bottle -Automatic High Speed

Categories : Labeling Machines

1. Application for labeling round and square shape containers. 2. Fully automatic rotary operation for 330ml-4000ml bottles.(with certain change of parts). 3. Machine frame made of stainless steel 304. 4. PLC electronic control, touch screen monitor and electronic speed control(frequency inverter). 5. With a star-wheel carrying containers firmly while dispensing , provide stable dispensing performance under high-speed operation. 6. Use servo motor to synchronously tracks label supply, label cutting and use specially designed vacuum drum to ensure precise labeling. 7. Three-phase PLC and AC variable control with a synchronized tracking and control system to maintain label cutting accuracy in different running speed. 8. Centralized lubrication system for easy maintenance. 9. Detecting in feed situation with sensor, automatically adjust labeling speed according to feeding situation of production line, making production line coherent. 10. System safety device: when malfunctions such as irregular torques and abnormal feeding occur, machine will automatically stop for operation safety and machine durability. 11. Automatic label proofread system controller made in Germany. 12. Automatic speed self adjustment to contact other machine.

Secondary Packaging - Labeling - ABL-M

Categories : Labeling Machines

The labeling equipment is suitable for glue type labels. The entire equipment is mechanical controlled system to stabilize machine operation and output productivity. Minor parts change and simple adjustment is necessary for different products to be convenience to machine application.

VALVE GATE-SVDT

Categories : Hot Runner Systems

For the valve pin bushing is integrated with the nozzle, the structure of manifold become very simple, and therefore this series is most suitable for the multi-cavity application. There is a pin in the nozzle and drive by pneumatic or hydraulic to open or close the nozzle. When the valve pin open / close can control the melt filling. Especially for the big gate design, the valve pin will seal the gate after packing process to prevent the stringing and get the unapparent gat mark.

VALVE GATE-AVMT

Categories : Hot Runner Systems

Suitable for large-scale parts or complex shape parts. There is a pin in the nozzle and drive by pneumatic or hydraulic to open or close the nozzle gate. When the valve pin open / close can control the melt filling. Especially for the big gate design, the valve pin will seal the gate after packing process to prevent the stringing and get the unapparent gate mark. For the multi-gate mold design, using the sequence control can eliminate the weld line problem.

YD Vertical Four-Column/Two-Color Rotary Table-Vertical Clamping and Vertical Injection Molding Machines

Categories : Vertical Injection Molding Machines

A. Standard double injection Vertical 4-columns direct-pressure clamping. In the upper mold plate, two separate vertical injection units is installed(separate injection hydraulic oil route) with the addition of round disc for this double injection machine. - Clamping force is 90- 500TON. Computerized and exclusively configured hydraulic system is used, which is more suitable for the production of general products( or special double-material) injection molding. - Two molds are installed on the upper mold plate while three lower molds are installed on the disc. When molding, the disc rotates alternatively at 120°to complete the two-color (two-material) injection molding or overmolding. - Highly efficient disc with water jacket device in the middle for cooling of the lower mold. - Expandable computer programs and special multistation disc (i.e. two upper molds and four lower molds). In the two lower modes, automated embedding and removing devices can be installed optionally to achieve automation of the whole machine work and increase production efficiency. B. Other double injection machine: - Type 1: A set of independent vertical “injection units” is added onto the upper mold plate of the original injection machine to form a double injection machine. Example: YH / YR / YC models + vertical injection. - Type 2: On the original injection machine, one or more sets of independent horizontal (level) injection units is combined to form a double injection machine. - Example: YH / YR models + horizontal injection - Type 3: The two-colors injection molding machine is combined to form a double injection machine by sharing a common disc. - Example: a. YH model + YT model + disc (2 ~ 4 stations) b. YH model + YH model + disc (2 ~ 4 stations)

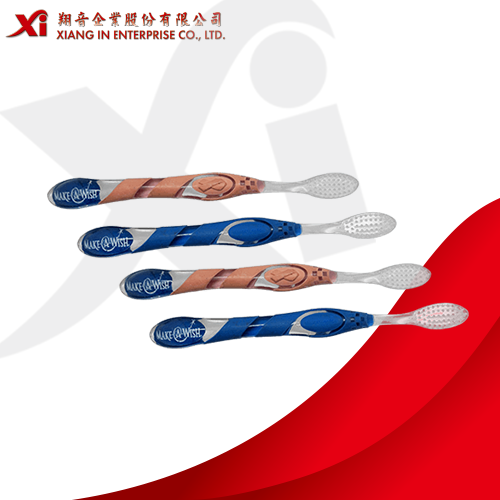

Heat Transfer Film for Toothbrush

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. All kinds of Acrylic plastic products can use heat transfer, as long as the surface is smooth and flat. Look like is transparent is the characteristics of acrylic material, but that make the appearance look monotonous. Now if use heat transfer technology, your design and product can be perfectly combined, and the design can be translucent or opaque, using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

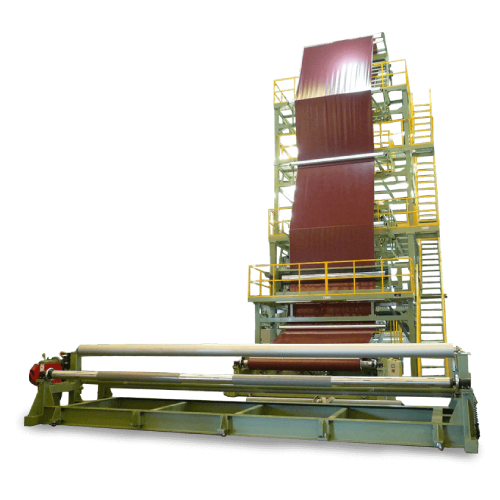

Agricultural Film and Geomembrane Blown Film Machine

Categories : Blown Film Extruders

The films is greatly helpful in agriculture and geomembrane. - Greenhouses that could increase the temperature to improve the growing environment and increase the available areas for planting, especially in high latitude and cold regions. - Mulch films could prevent the soil moist loss and preserve the temperature to keep soil warm that provide a suitable environment for seeds and sprout. - Silage films and stretch films is also more popular to store silage, hay and maize. - Geomembrane film could used to the construction for preventing leakage, water diversion for irrigation and reservoir and non-slip at side slope. Specification Layers: 3 / 5 layer Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. Opened film width range in 6 - 20 meters Designed output range 600 - 2000 kg/hr

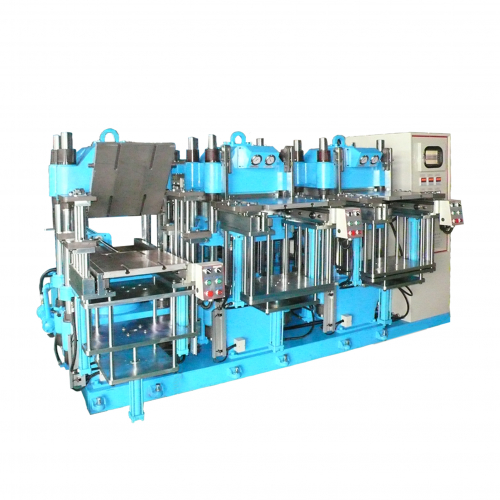

3 Stations 3RT Mold-Open Rubber/Silicone Compression Molding Machine /HCC-T3

Categories : Compression Molding Machines

Features This type of machine is multi-functional, because it is suitable to be used for top opening triple or four molds. Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously. Slow speed of mold calibration is provided to make the calibration safer and more accurate. Molds can be precisely positioned. A 100% safety design for positioning is available to prevent molds from damage. The speed to open/close the mold is adjustable. It is very accurate and reliable.