High Speed Precision Vertical Injection Molding Machine-YQ Series

Categories : Vertical Injection Molding Machines

• Vertical four-pillar vertical clamping, with vertical injection. • The square pillar design comes with large mold size. The space within the column allows customers to install devices of automatic embedding and removing products. This allows automation for the whole machinery. • Big L / D ratio of screw, plasticizing evenly, suitable for injection molding of engineering plastics. • High standard computer control system with high precision injection pressure and high response injection speed. The quality is more stable for high-precision embedded injection molding products. • 1S single sliding: After mold opening, the lower mold will automatically slip in front of the operator for facilitating embedded molding operation. • 2S double sliding (Alternating double sliding): One mold for injection molding, another mold for taking out and putting on embedded parts operation. • 2SL double sliding (90°Alternating double sliding): One operator can operate independently. One mold for injection molding, another mold for material taking and putting on embedded parts. The two slidings are intersecting at 90 degrees, which can lower the production cost, and enhance the performance. • Able to combine automation and the high-speed injection can effectively enhance the production capacity. • A variety of circuit design (half closed servo hydraulic or high speed injection) to meet the customer’s requirements.

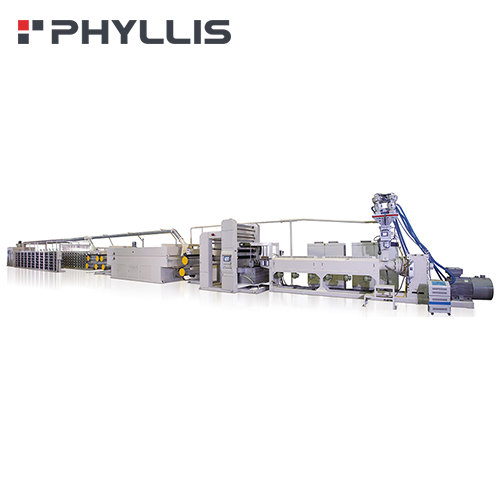

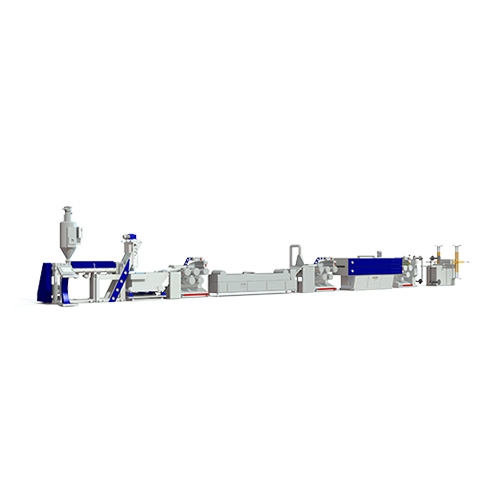

Extrusion Tape Line (Standard Tapes)

Categories : Tape Extrusion Machines

One layer extrusion tape line for producing PP, or HDPE flat tapes. With melting capacity from 120kg/hour to 620kg/hour, producing films width from 460mm to 1400mm. Tape Winding speed from 250m/min to 380 m/min, which produces premium quality tapes for use in woven sack, Kraft Paper cement sack, PE Tarpaulins, and various applications.

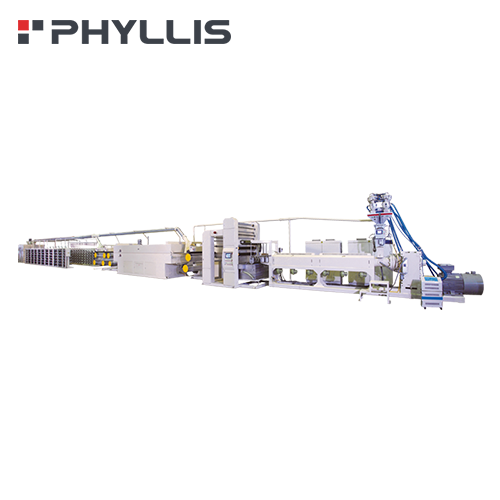

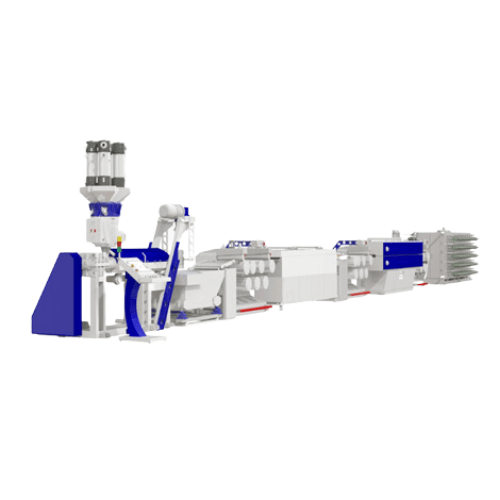

Extrusion Tape Lines (HDPE Tapes)

Categories : Tape Extrusion Machines

One layer extrusion tape line specialized for producing HDPE flat tapes, which produces premium quality tapes dedicated for use in PE Tarpaulins, and various applications.

Primary Packaging–General - Filling/Closing - AFC-60V

Categories : Capping Machines

The liquid packaging equipment compliances with cGMP liquid production guidelines and the common application is for below 60mL low viscosity products.

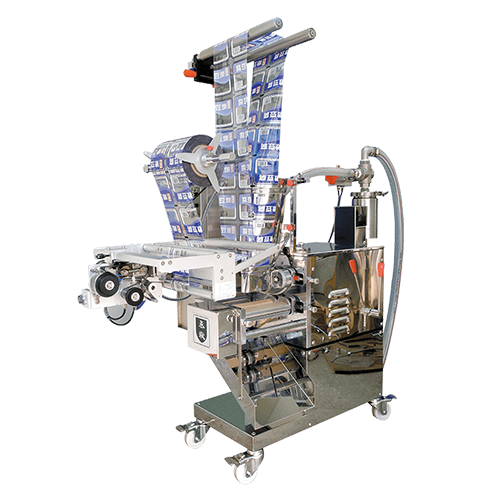

Liquid & High Concentration Sauce Packaging Machine - TYPE-857

Categories : Liquid Packaging Machines

• Application Products : Liquid : tea、juice、water、shampoo、soy bean sauce、bathing lotion、liquid sauce and other pure substance. Density : Tapioca、cream、jam、BBQ sauce、meat sauce、salad、facial lotion、chili、tomato sauce、butter and the similar. • Features : Automatic bag making → measuring → filling → sealing → cutting →finished products conveying. • Packaging Materials : Heat sealable laminated film (such as : Nylon + PE,OPP+PE,Alum foil + PE & other similar beat sealable film)

Bottle Filling Machine

Categories : Labeling Machines

FEATURES : 1. Made of SUS#304 corrosion resistant stainless steel and aluminum alloy 2. Filling volume and speed can be adjusted easily PLC control system with HMI touch panel for easy management 3. Memory storage of 15 to 20 sets for future usage 4. Ball-valve shut-off nozzle prevents liquid from dripping down 5. Dipping nozzles can prevent spillage and diminish bubbles 6. Capacity depends on filling nozzles, product and volume. 7. Machine is customized 4 - 12 filling nozzles. 8. It can be optional combined with the capping machine, labeling machine, shrink machine… 9. Piston pump filler is standard equipment, servo filler is optional. APPLICATIONS : Shampoo, Engine oil, Motor oil, Hair condition, Lubricant, Water, Sauce and other liquid or paste products …..etc..

Horizontal Bag Filling & Sealing Machine

FEATURES : 1. Design for the most versatile packing applications. 2. The outer structure of machine is shielded with SUS304 stainless steel for ease of cleaning and maintenance. 3. Fitted with automatic weighing, filling machines, date corder, and conveyor (optional) to suit various materials. 4. Rated weigh within 2000 Grams per bag. APPLICATIONS : Juice, Jelly, Plum Jelly, Yugum, Red bean paste, Tea bag, Coffee bag, Powder, Granule, Melon seeds, Beans, Candy, Detergents, Mask, etc.

Primary Packaging–General - Filling/Closing - CJ-250

Categories : Capping Machines

The liquid packaging equipment compliances with cGMP liquid production guidelines and the common application is for above 60mL low viscosity products.

Primary Packaging - General Filling - AF-80

AF-80 liquid filling equipment common application is for above 60mL low viscosity liquid products such as collagen healthy drinks, mouthwash and etc. In order to meet customer’s various requirements, minor modification for the equipment is also applicable.

Primary Packaging-General Filling-AF-80S

AF-80S liquid filling equipment common application is for above 60mL high viscosity liquid products such as shampoo, honey etc. The filling procedure applies piston filling method with pneumatic check valves and nozzles to minimize liquid leaking after filling procedure is completed.

Bristle Monofilament Extrusion Line (JC-MNB Series)

Categories : Extrusion Lines For Filaments and Yarn

JC-MNB series monofilament extrusion line designed exclusively for the manufacturing of virgin and/or recycled polyester (PET) and polypropylene (PP) for broom and brush application.

Danline Monofilament Extrusion Line (JC-MND Series)

Categories : Extrusion Lines For Filaments and Yarn

JC-MNP series Danline Monofilament Line designed with double-stage-drawing and heat setting. The line is specially conceived to process high tensile strength monofilament for varies industrial applications.