Tape Extrusion Line (JC-FY Series)

Categories : Tape Extrusion Machines

The JC-FY series flat tape yarn extrusion line is available in 85mm and 120mm screw extruder, designed to produce tape line for various applcations, an ultimate solution offering combination of efficiency, reliability, performance, and premium quality tape product.

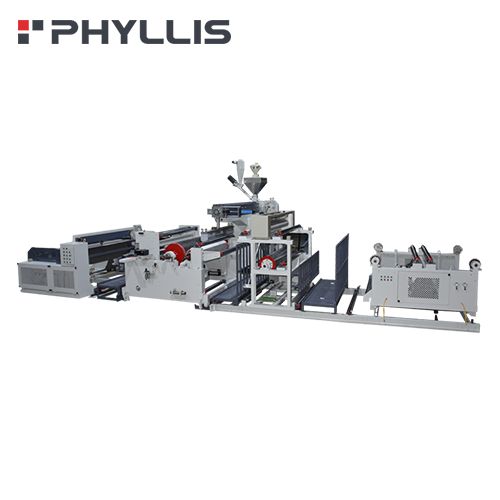

Lamination Line (FIBC, Tarpaulin)

Categories : Extrusion Lamination Machines

Lamination application for flat fabric of PP or HDPE. High level of coating technique provides smooth and even coating surface, which reduces material waste, while maintaining highest quality of coated fabric.

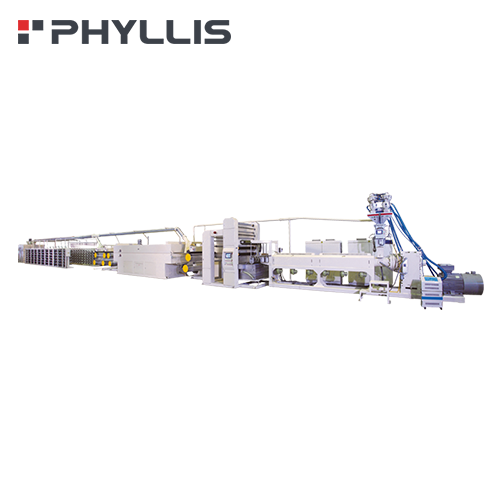

Extrusion Tape Line (FIBC Tapes)

Categories : Tape Extrusion Machines

One layer extrusion tape line specially designed to produce PP tapes for high performance application at premium quality mainly used for FIBC fabrics, and various technical applications.

Circular Loom (Heavy Duty Fabrics)

Categories : Industrial Knitting Machines

Consistency with simplicity and flexibility, the looms are easy to operate and maintain, while producing high quality heavy duty fabrics suitable for FIBCs, Tarpaulins and other special textiles.

Coating Dies Slot / Slit

Categories : Extrusion Dies / Dies Heads

Slot/Slit design, excellent manifold geometry design, solvent resistant alloy, super mirror grinding technique SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid Straightness precision is made by GMA exclusive grinding technique to reduced film thickness deviation of groove width. Interchange shim for variable lip gap application. Special stainless steel resists to a full range of solvents. Work with automated controller. Manifold geometry simulation analysis technique and optimum manifold design base on customer’s material. Uniform and stable flow distribution. No coating line defect with even thickness at high speed. Professional Slot Die maintenance service by third parties is acceptable.

Wire rope coating PVC、PA12 extrusion line

Application: Coating PVC or PA12 on wire rope to protect wire

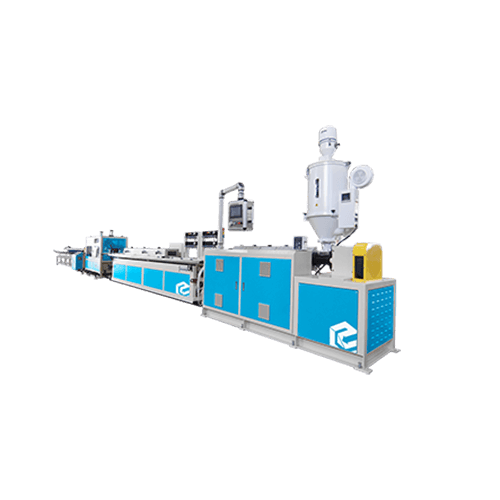

Profile Extrusion Machine Line

Categories : Extrusion Lines For Pipes and Profiles

Everplast's profile extrusion machine production line has many applications, including PVC building materials, decorative materials, the automotive industry, and other PP/ABS/PC/PMMA profiles of different materials in daily life. Everplast can plan suitable single screw/parallel type twin screw/conical type twin-screw production lines according to the profiles and materials required by customers. With excellent mold manufacturing and testing experience, we provide professional and comprehensive special-shaped extrusion processes and equipment.

Cosmetic Bottle / Detergent Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

Small Blow Molding Machine

Categories : Electric Blow Molding Machines

Small-Continuous Type Blow Molding Machine This series model can produce small size containers ranging from 20mL to 10L for applications such as cosmetics, beverages, edible oil, pharmaceutical use, chemicals, housewares, and other industrial purposes. With the energy-saving system option, this machine can save up to 20% of power consumption. Some of the most common applications for small blow molding machines are: Lubricant oil bottles Laundry detergent bottles Cosmetic bottles Pesticide bottles Pharmaceutical bottles Multi-color kettles PVC cans Moreover, small blow molding machines can be customized according to the client’s needs of production: It can be a single or double station machine A visible stripe extruder unit can be added to observe liquid level It can include an auto-deflashing unit and many other features to make the machine as automatized as possible. An automatic extrusion blow molding machine is many times preferred because it leads to the reduction of manpower need which results in reduced costs, increased efficiency, and time savings for an organization.

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

Water Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

Edible Oil Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging