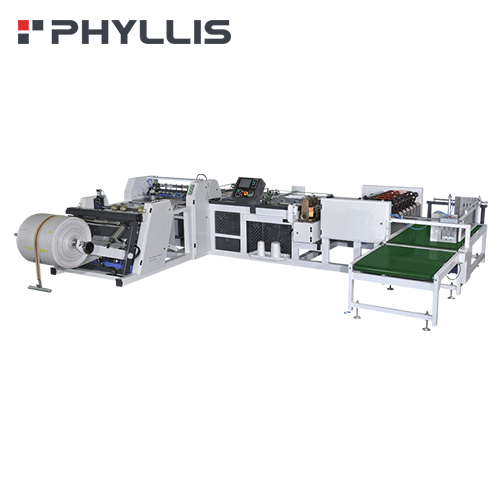

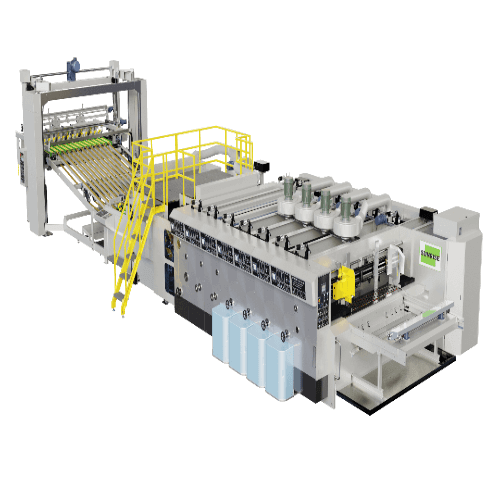

Conversion Line (Cutting-Sewing)

Categories : Cutting Machines

The new generation of woven sack conversion line for bottom-sewn sacks is suitable for coated and uncoated woven fabric, BOPP film laminated fabric, and leno fabric. With great variety of options, a wide possibility of applications is brought for the customer.

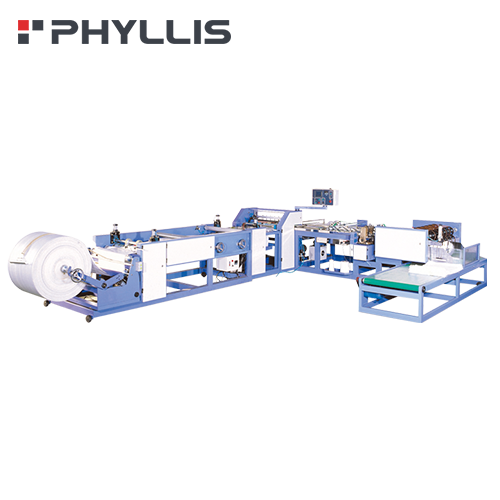

Conversion line (Gusseting-Cutting-Sewing)

Categories : Cutting Machines

The new generation of woven sack conversion line for bottom-sewn sacks is suitable for coated and uncoated woven fabric, and BOPP film laminated fabric. With great variety of options, a wide possibility of applications is brought for the customer.

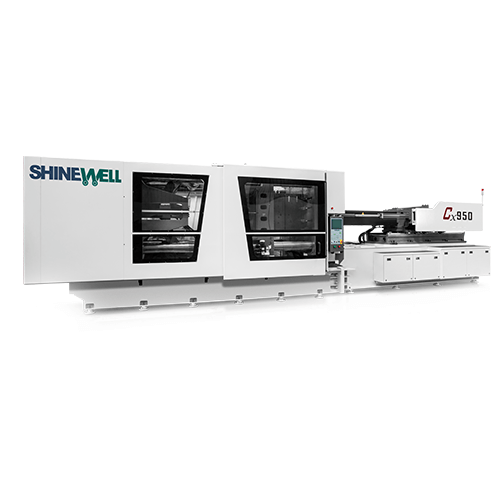

Servo Energy Saving Injection Molding Machine CX-60 – CX-1600

Categories : Horizontal Injection Molding Machines

APPLICATIONS:Packaging,Optics,Electronics,PET Preform,Closures,Cutlery,Thin Wall,Automotive

Perforation And Slitting Machine

Categories : Slitters and Rewinders

The World Steel perforation and slitting machine is the best choice when it comes to customizing your film for packaging and agricultural applications. It is able to process a range of types of single layer polypropylene films and optional equipment can be added to improve production accuracy and quality. Some of these options include: PLC device to monitor and control inputs and outputs, a scrap coiler to collect your waste film, core cutting machines for paper tube preparation and a specialized hot needle wheel for pinpoint accuracy.

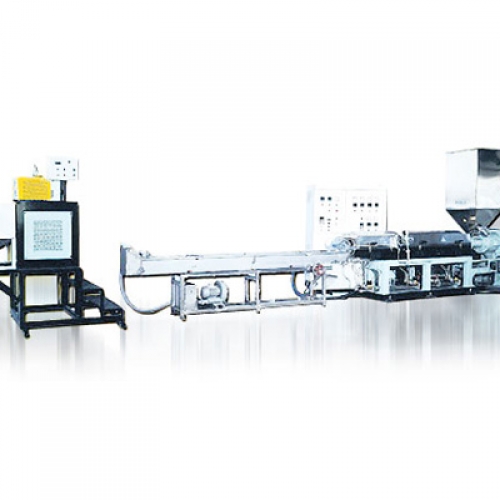

Dyeing and Pelletizing Plant

Categories : Plastic Pelletizer Machines

• Model: TY-DB Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS. • Specific resin: PC, PET, ACRYLIC, NYLON. • Capacity: 50-1000 kg/hr

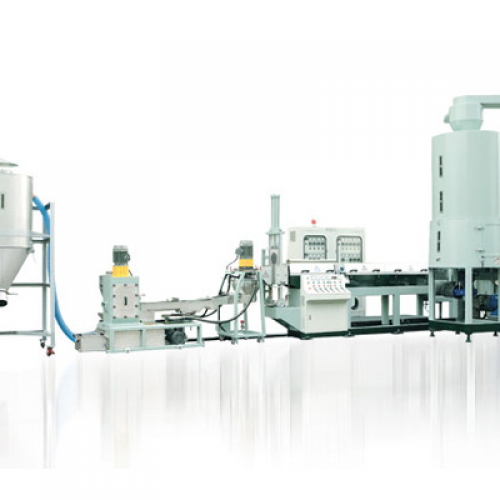

Eco-Friendly Plastics Recycling Extruder Series Water Cooling

• Model: TY-LW Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS, HIPS. • Specific resin: POM, PC, ACRYLIC

Eco-friendly Two-Step Die-Face Cutting Recycling Machine Water Cooling

Categories : Plastic Pelletizer Machines

• Model: TY-LBW Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS, HIPS. • Specific resin: POM, PC, ACRYLIC • Capacity: 100 ~ 800 kg/hr

AB & ABA CO-EXTRUSION BLOWN FILM MACHINE

Categories : Co-Extrusion Blown Film Machines

Equipped with 2 extruders, A/B or A/B/A type blown film machine is able to produce two-layer film. Co-extrusion able to choose from AB to ABA, ideally for 2 layer film with different colour or apply CaCO3 in middle layer for cost saving, etc. Perfectly suitable to agriculture film, shipping bags, shrink film, consumer packaging and many others.

5 Gallon Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging

Flexo Printing & Converting

Categories : Wrapping Equipment

Sunrise Pacific Co., Ltd. offerings, Versatility and Material Adaptability: Powering Your Solutions Streamline Success: Embrace Inline Automation Simplify Your Print: Effortless Printing Made Easy Maximize Efficiency, Small-sized Investment: Small Steps, BIG Gains! Applications: Packaging of Agricultural Product, Vegetable & Fruit, Electornics, Food, Beverages & Drinking Water, Industrial Products, Postal & Courier, Air Freight, Sea Freight, Household Goods, Daily Necessities and Others. Main Features: Easy operation, fast order change Fast RETURN print job feature Air loaded anilox roll positioning Auto ink washing timer feature Quick-lock or Matthews print plate mounting system Slot register, pre-creaser & creaser caliper Anvil trimming system with variable speed anvil Please reach out to us for further information on product features.

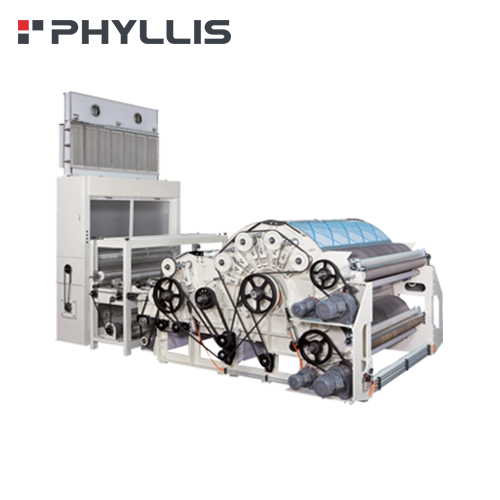

Carding Section

Categories : Non Woven Production Line

A complete carding section including fiber pre-opener, blend bin, fine opener, hopper feeder, weight pan, carding machine, cross lapper and other peripheral equipment. Taylor made complete carding line according to customer’s needs leads to great flexibility of production

OPEN GATE-NL ANPT

Categories : Hot Runner Systems

There is a torpedo inside the nozzle to have a circularity gate and guide the melt along the torpedo to flow into the cavity, and therefore can reduce the production of cool plug. This series is very popular for unapparent gate mark. When the melt has added with glass fiber and has strict requirement to the flow mark that will need more attention.