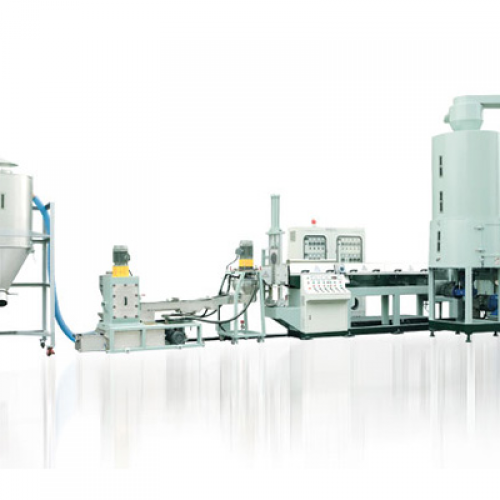

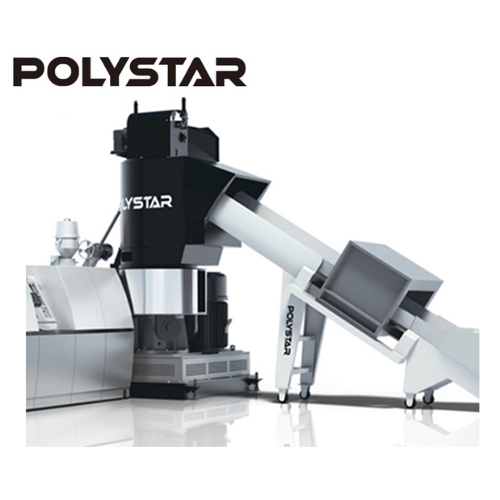

• Model: TY-LBW Series

• Country of Origin: Taiwan

• Applicable resin: PP, PE, ABS, PS, HIPS.

• Specific resin: POM, PC, ACRYLIC

• Capacity: 100 ~ 800 kg/hr

• This model applied to recycle & plastic film and plastic lump, also for the pelletizing after equipment cleaning.

• Die-face cutting is easy to operate, and not only saving the labor cost of pulling tape, but also the installed space.

• Built-in melt pressure sensor for filter screen replacement reminder to prevent related equipment damage from excessive pressure.

• Two sets of vent improve the discharge and evaporation of liquid in barrel in speedy pace.

• Secondary machine built-in vacuum degassing device is capable of removing plastic powder mixed gas, steam and volatile matter, and improving plastic material quality. (As optional equipment for host)

• Side Forcing Feeding method contributes to incoming material stabilization, and , productivity improvement.

• It is unnecessary to stop the machine during replacing the filter hydraulic screen changer.

• Plastic pellet feeding hopper and Color Masterbatch feeding hopper are as optional equipments for simple mixing dyeing effect.