OVER INJECTION MOLD

Categories : Injection Molds

Over Molding is the process where one material is precision molded over another material, usually rubber (TPE) over plastic, for visual or ergonomic appeal. Very often when the design requires ” soft touch” or waterproofing (IP68), over molding is the manufacturing process that we will use. For over molding success, knowledge of material compatibility is crucial. Our extensive expertise in this field helps assure your end part will have the strong end-application bond and performance that your product success demands. Insert molding can also be combined with over molding using parts made of aluminum, brass, stainless steel, copper, plastic and more.

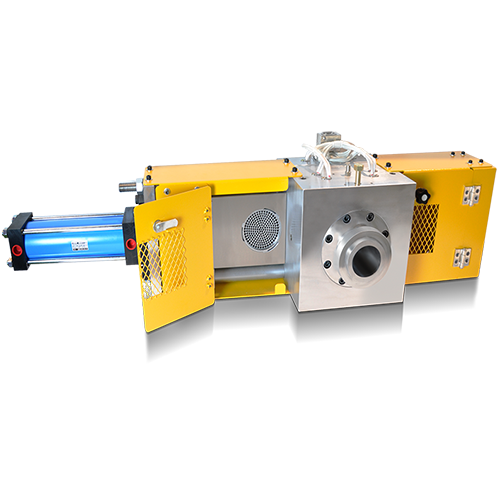

Screen Changer

Categories : Screen Changers / Filters

HYDRAULIC SLIDE PLATE Hydraulic system, easy for operation. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : for extrusion products such as sheet and films. Hydraulic system, easy for operation. NON-STOP SLIDE PLATE Streamline and smooth channel for easy clean and little polymer stagnation. Interruption free and few bubbles caused by filter replacement. Hydraulic system with nitrogen accumulator for easy and fast operation. Fast slide plate movement for non-stop production. Materials : most polymer. Application : for extrusion products such as opitical, sheet and films. DUAL SLIDE PLATE Continuous production process. Interruption free filter replacement. Hydraulic system is driven by solenoid valve for easy operation. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for sheet products. DUAL PISTON Continuous production process, air does not enter the production process. Interruption free by filter replacement. Hydraulic system is driven by solenoid valve for easy operation. Optional auto-venting system. Can be equipped with a fully automatic exhaust. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for optical, sheet, film and other products. LARGE FILTRATION Continuous production process. Special venting design that no air enter the process during screen changing. Hydraulic system is driven by solenoid valve for easy operation. Optional auto-venting system.Can be equipped with a fully automatic exhaust. Can be equipped with a fully automatic exhaust. The filter area is about 2~5 times larger than the Dual Piston. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for granulation, sheet, film and other products. BACK-FLUSH Interruption free filter replacement. Low pressure difference for stable and continuous production during filter replacement. Maintain 75% filtering area during filter replacement and backwash. Safety cover design improves operator safety. Automatic backwash and exhaust function for cutting filter replacement loss, operating requirements and scrap reduction. High wear-resistance, high pressure resistance, high-precision filter design provides effective filtering area and filter quality. Materials : most polymer. Application : suitable for recycle, granulation, packing tape and film. MANUAL WITH LEVER GEAR Easy operation with lever gear. Energy saving without driven system. Easy to clean when changing materials or colors frequently. Machine shutdown before filter replacement. Machine shutdown before filter replacement. Application : usually applied on sheet line, blow line and lab machine. SELF-CLEANING FILTER Interruption free filter replacement. Large filtering area, applicable with a larger mesh count. Manual back wash. Energy saving without driven system. Materials : most polymer. Application : usually applied on sheet , lamination and film line. CANDLE TYPE Compact mechanical design for higher mesh count to extend filter time. Manual network change, no hydraulic system. Adjustable pressure control during production to increase the effect of mixing in the screw. Application : applied on Lamination and film line.

Kneader Ruder (DAKE-Series)

Categories : Dispersion Kneaders

The Open Kneader With Ruder Is Available With a「Variety Of Blades In Different Shape Design As Well As With Number Of Discharge Methods And Mixing Conditions」, Has Already Achieved Applications Considerable Various Of Industries That Deal With Such High And Medium-Viscosity Materials As Adhesives, Hot-Melt Material、Silicon Rubber、BMC、Ceramics、Fiberglass、Magnetic Compounds、Printing Inks、Tapes、Thermosetting Resins、Food、Cosmetics、Pharmacy Etc.

RF-448

Categories : Labeling Machines

Round bottle hot melt glue OPP Labeler Available for 250cc~1500cc (bottle diameter 50mm~120mm) filled r un-filled round bottle shape labeling application as mineral water bottle, drink bottle, glass bottle, PET bottle, stable speed reaches to 400~600BPM.

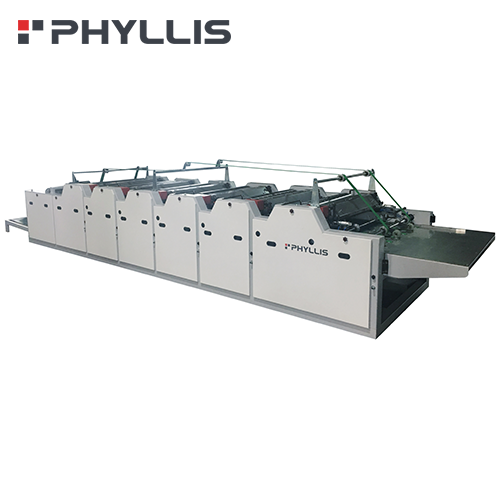

Flexographic Printing Machine (Manual feeding type)

Categories : Flexographic Printing Machines

Combination of simplicity and user-friendly design, the manual feeding type flexographic printing machine provides excellent price/performance ratio for small and medium scale purpose.

PET/PC One Stage Injection Blow Molding Machine FS-BT

Categories : Injection Blow Molding Machines

FS-BT-S is equipped with 2-station servo table and side-blow system. After preform injection, the servo table rotates 180 degrees, a servo screw then transfers a neck plate with PETIPC preforms to the side-blow station for blowing bottles. Using side-blow system is available and flexible for a bigger work place, and optional devices; gate trimmer (preform tail cutting device) and product conveyor can easily be mounted inside the machine to go on the automatic production. This model is good for small containers with short cycle time. Jar/wide-mouth bottle available, FS-BT-J has the same benefits of FS-BT-S, but is for wide-mouth jar applications, and it's a stronger machine with higher injection capacity and stronger clamping force. Innovative approach by 2-station machine operation, FS-BT-S/FS-BT-J need less neck cavities, less mold cost, and has a more effective mold width to save the total cost. Mold cost is an important investment in running diversified and various products lines. The tooling'mold cost in our simple and innovative system is the lowest of all.

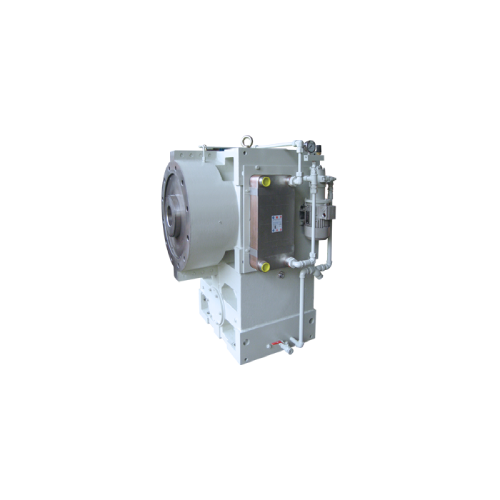

for Extruder Machine - Single Screw Tex Series

Categories : Gearboxes

CASE Material: FC 25 module cast iron GEAR SHAFT a. Material : SNCM220.Carburization & Hardness HRc56∘~60∘ b. Gear precision: reach JIS 2 level GEAR Material: SCM420 Carburization & Hardness HRc56 ∘ ~58∘ b. Gear precision: reach JIS 2 level OUTPUT SHAFT Material: SCM440 Hardness: reach HRc28 ∘ ~32∘ High Frequency Heat Treatment in HRC 48〫-52〫 in the connected area of Oil Seal Bearing Brand : SKF 、FAG、NSK (OPTION), Oil Seal : NOK or SKF Brand, material: Viton Lubrication System : OIL BATH SPLASH TYPE Forced type (Elements including as below) Motor PUMP(1HP/220/380V+Rop210HA) Teco Brand Cooling device(plate type) or Cylinder type Y Type Filter Temperature Gauge Pressure Gauge Pressure Switch Gear Measuring Report : Lead/Profile/Pitch testing Report Operation temperature rising: below +40 ℃ (Ambient temperature) Operation Vibration < 2.3mm/sec Operation Sound < 80Db, None Oil Leakage

Needle Punching Section

Categories : Hydraulic Punching Machines

A complete needle punching section including feeding system, pre-needle punching machine, finish needle punching machine, edge cutter, and other peripheral equipment. Taylor made complete needle punching line according to customer’s needs leads to great flexibility of production. Wide range of application covers geotextile, car carpet, filtration, mattress, and more.

Secondary Packaging - Cartoning - CSC-50A

Categories : Cartoning Machines

The cartoning equipment applies the vertical automatic production operation. The equipment is suitable for more types with medium capacity products

EXTRUDER FOR PVC/TPO SOFT FILM

Fruitive International Co. helps consult and design different types of PVC / TPO soft products extrusion line for customers and suitable for a variety of PVC / TPO soft products production. It is applied to products such as PVC tablecloth, shower curtain, tiles backing, transparent film car decorative, flloring, TPO tablecloth, printed film and so on. The extruder and calender unit that consists of rollers is also the core equipment of a production line. Hence, this is important when choosing the right products. We always make every effort to assist our clients to select the requested products in regarding to some technical aspects such as length and diameter ratio of the extruder, the width and the material of the calendar roller with the maximum capacity in order to meet the aimed production capacity and product demands. We achieve making the best thickness contribution by adopting the technology of moving rollers, roll bending, and other means. It is also an option to equip the most up-to-date full automatic control as well as the thickness monitor on our calenders.