INSERT INJECTION MOLD

Categories : Injection Molds

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

LIQUID INJECTION MOLDING

Categories : Silicone Injection Molding Machines

Liquid Injection Molding (LIM) and Transfer Molding are preferred processes for manufacturing solid silicone rubber items used in a wide range of applications such as medical equipment, watersports, gas masks, military gear, waterproof device cases, 3C products and much more. MATERIALS: Shin Etsu / Dow Corning/ GE Silicones ADVANTAGES & APPLICATIONS: Low viscosity and lower injection pressure, good for silicon molding Good chemical stability and environmental protection High dimensional accuracy It produces high quality parts without secondary finishing and allows much shorter production cycles than other processes. Over-molding together with hard plastic frame (PC or ABS etc.) for waterproof devices, shock proofing, shielding, etc. Very thin wall design (0.25mm thick around) for silicone to adhere on plastic housing (rib) to meet the demand of low profile product design. Water proof feature can be secured by the combination of soft rubber contacts and with constant pressure provided by hard plastic housing (rib).

Polyamid 66 - NBE1200G20

Categories : PA(Polyamide) /Nylon

Glass fiber 20% reinforced. Super high impact.

HIGH-ACCURACY ROLL-TO-ROLL AUTOMATIC FEED CUTTING MACHINE TRC-350SP

Categories : Foaming Machinery

Double-Axle Synchronous Feed Mechanism: Enhances the production speed and Yield Rate through double-axle synchronous feeding. Well-Designed And Stabilized Bottom Dead-Point Accuracy: Uses the patented Bottom Dead-Point Mechanism exclusively developed by TRURAN to achieve +/-0.005mm of repeated positioning accuracy. High-Accuracy Depth Adjusting Mechanism: Uses high-accuracy mechanism to achieve 0.01mm of fine-tune accuracy (0.001mm is for optional). High-Efficiency Boosting Circuit: Reduces over 30% of power consumption as compared to conventional circuit. Photoelectric Material Flexibility: Uses as the dedicated moving system according to the material characteristics. Unique Material Moving Mechanism: High-stability servo control system is used to avoid contaminating and scratching the material. Automatic Lubrication Mechanism: The entire machine uses Automatic Lubrication Mechanism to reduce daily maintenance work. Waste Recovery Mechanism: The System will recover the waste of cutting automatically to save space, while enhancing the operability.

Perforated Bag on Roll Making Machine (Coreless)

Categories : Plastic Bag Making Machines

● Germany made high-sensitivity photo cell device which can catch printing mark correctly. ● When the print is inaccurate position, the machine will stop automatically.

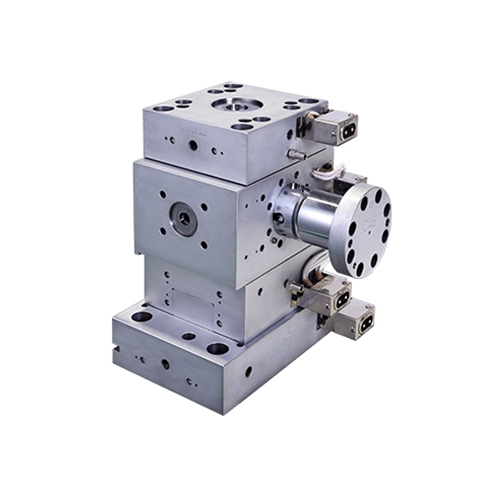

Fix / Variable / Rapid Geometry Feedblock

Categories : Extrusion Dies / Dies Heads

FIX GEOMETRY Simple manifold structure, few retention points Customized manifold design, 2 or 4 inlets, for different Extrusion Die inlet as required by the customer Precision internal manifold design along with special surface treatment Corrosion, heat and wear resistant design Manifold design varies with rheology property of polymer material to adapt to features and strength of rheology of melted polymers Applicable with multi-layer composite production requirements of different materials SUITABLE AVAILABLE FOR HEAT SENSITIVE POLYMERS INCLUDING ABS, PA, PC VARIABLE GEOMETRY Direct changing thickness of individual layers during production Easy operation, production costs reduction. Multi-layer space design according to product requirements. Interchangeable selector as required by customer to adapt to different products and changing layers required by the customer. Precision internal manifold design along with special surface treatment. Corrosion, heat, and wear resistant design. Adaptive to features and strength of rheology of melted polymers. Applicable with multi-layer composite production requirements of different materials. SUITABLE APPLICABLE WITH GENERAL POLYMERS SUCH AS PP/PE/PS RAPID VARIABLE GEOMETRY Direct changing thickness of individual layers during production Easy operation, production costs reduction. Multi-layer space design according to product requirements. Interchangeable selector as required by customer to adapt to different products and changing layers required by the customer. Precision internal manifold design along with special surface treatment. Corrosion, heat, and wear resistant design. Adaptive to features and strength of rheology of melted polymers. Applicable with multi-layer composite production requirements of different materials. SUITABLE APPLICABLE WITH GENERAL POLYMERS SUCH AS PP/PE/PS

Coating Equipment Slot Die Coater

Categories : Extrusion Dies / Dies Heads

To test liquid distribution and coat surface with different manifold, single or multi-layer coating process SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid Substrate: Film, Fabric. Customization is acceptable in terms of customer’s request.

Precision Gears

Categories : Gears

(1) Custom Design, double check by Germany KLINGELNBERG P150 MEASURING TRIAL EQUIPMENT to optimize its overall quality and precision. (2) Follow ISO 9001-2008 version, UT, MT testing are available as per customer required. (3) Inspection Report: Gear Profile Lead, Pitch Report

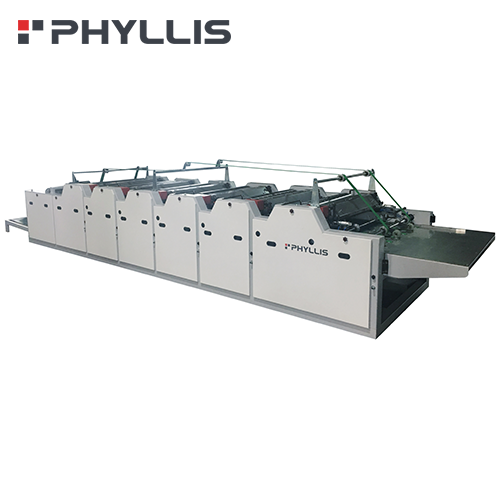

Flexographic Printing Machine (Manual feeding type)

Categories : Flexographic Printing Machines

Combination of simplicity and user-friendly design, the manual feeding type flexographic printing machine provides excellent price/performance ratio for small and medium scale purpose.

Kneader Ruder (DAKE-Series)

Categories : Dispersion Kneaders

The Open Kneader With Ruder Is Available With a「Variety Of Blades In Different Shape Design As Well As With Number Of Discharge Methods And Mixing Conditions」, Has Already Achieved Applications Considerable Various Of Industries That Deal With Such High And Medium-Viscosity Materials As Adhesives, Hot-Melt Material、Silicon Rubber、BMC、Ceramics、Fiberglass、Magnetic Compounds、Printing Inks、Tapes、Thermosetting Resins、Food、Cosmetics、Pharmacy Etc.

Polyamid 66 - NB1200G45

Categories : PA(Polyamide) /Nylon

Glass fiber 45% reinforced, high flow. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

EXTRUDER FOR PVC/TPO SOFT FILM

Fruitive International Co. helps consult and design different types of PVC / TPO soft products extrusion line for customers and suitable for a variety of PVC / TPO soft products production. It is applied to products such as PVC tablecloth, shower curtain, tiles backing, transparent film car decorative, flloring, TPO tablecloth, printed film and so on. The extruder and calender unit that consists of rollers is also the core equipment of a production line. Hence, this is important when choosing the right products. We always make every effort to assist our clients to select the requested products in regarding to some technical aspects such as length and diameter ratio of the extruder, the width and the material of the calendar roller with the maximum capacity in order to meet the aimed production capacity and product demands. We achieve making the best thickness contribution by adopting the technology of moving rollers, roll bending, and other means. It is also an option to equip the most up-to-date full automatic control as well as the thickness monitor on our calenders.