PET Stretch Blow Molding Machine - TEM08M3

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

Disc Coupling

Categories : Gears

(1) NO-LUBRICATION REQUIRED: No lubricants are needed and no noises or wear and tear produced because there is no sliding or friction. (2) MAINTENANCE-FREE: ”LEAVE IT FOR GOOD AFTER INSTALLATION” It lasts forever as long as is used correctly. (3) LIGHT WEIGHT W/HIGH TORQUE: By operations, it is available in a wide range; it can be made of aluminum alloy to reduce the weight. (4) LARGE OFF-CENTER ALLOWED: With large range of off-centering, it can be used flexibly in all kinds of transmission systems. (5) SUITS HIGH-TEMPERATURE APPLICATIONS: All-metal-pars construct makes it suitable for high temperatures. (6) BACKLASH-FREE: WITH GOOD TORSIONAL RIGIDITY Perfect for axial rotation that requires accuracy and machines with phase-control. (7) CAN BE USED IN EVEN HIGHER SPEEDS: It is highly balanced due to being backlash-free and light weight. (8) EASY TO INSTALL: Comprising small number of pasts and being compact, it can be installed/uninstalled quickly. (9) ROBUST STRUCTURE AND HIGH SAFETY COEFFICIENT: With load stress kept at low standard, it works with very high safety coefficient. (10) AUTOMATIC PROTECTIVE DEVICE: In case of damage, an automatic protective device rotates via pads.

Polypropylene - PP1200G15

Categories : PP Resin

Glass fiber 15% reinforced. Application: Fan blades, Hand tools, Gardening tools, Sports equipment, Home appliances parts, Medical rehabilitation equipment, O.A. Office components.

Secondary Packaging - Cartoning - CSC-50A

Categories : Cartoning Machines

The cartoning equipment applies the vertical automatic production operation. The equipment is suitable for more types with medium capacity products

KA-7000T Slide Air Press Series

Categories : Bag Making Machine by Applications

High Frequency Plastic Welding Machines For PVC,PEVA,TPU, thermoplastic plastic welding, etc.. Applied to manufacture of auto parts, electrical products, toys, stationery, household goods and dinnerware, etc..

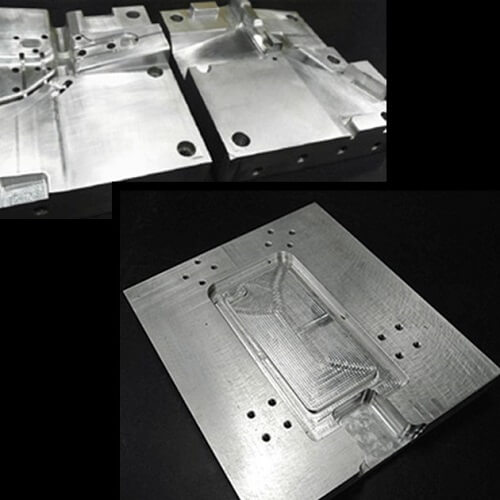

SOFT TOOLING

Categories : Hot Runner Systems

For small production runs or for prototyping, soft tooling is a fast and low cost way to build multiple copies of your product. To provide quick mold soft tooling services our engineers were sent to Japan to learn from soft tooling experts. MATERIALS: Cavity & Core Insert Made from Aluminum or Steel, Mold base free ADVANTAGES: Low Cost & Short Lead Time (5-10 days) Useful for R/D testing and trail runs, reduces final tooling risks Can product approximately 500 Shots DISADVANTAGES: Soft tooling will cycle slower due to poor thermal conductivity of mold material. Material life of soft tooling is limited and will depend upon part complexity. Our mold fabrication shop is equipment with high-end Charmilles EDM and OKK CNC machines. Please visit our Mold Fabrication page for more details.

Open Kneader (DAK-Series)

Categories : Dispersion Kneaders

The Open Kneader With Ruder Is Available With a「Variety Of Blades In Different Shape Design As Well As With Number Of Discharge Methods And Mixing Conditions」, Has Already Achieved Applications Considerable Various Of Industries That Deal With Such High And Medium-Viscosity Materials As Adhesives, Hot-Melt Material、Silicon Rubber、BMC、Ceramics、Fiberglass、Magnetic Compounds、Printing Inks、Tapes、Thermosetting Resins、Food、Cosmetics、Pharmacy Etc.

PC/ABS Alloy - FR-CA8271AHF

Categories : Alloys

Flame retarded, black colored. Application: Electronic, Electrical cases, Thin-wall application, Automotive parts.

Gear Coupling

Categories : Gears

(1) Crowned tooth allowed larger tolerance in shafts and higher loads. (2) Special hardening treatment W/high strength and anti-abrasiveness. (3) Closed type coupling--easy lubricate & anti dust as well as no leakage. (4) The type of TIEN YI GEAR SHAFTS COUPLINGS had been successful the first processing, it must be done the second procedure heat treating again according to material. And it were given them more rigidly precise, increasing stronger tenacity. At last removing gravitation by striking-ball bearing when those steps all finished.

Bimetallic Screw

Categories : Screws and Barrels

With a view to meet the ever increasing market demands, present day plastic processors have resorted to the use of plastic raw materials which included all kinds of sophisticated ingredient such as glass fiber additive, carbon fiber, mineral stone powder additive, heat-resisting chemical additive, etc., thereby causing serious abrasion and to the barrel and screw as well as reducing their life span. To meet this challenge, our Co. had several kinds of screw which has shown a remarkable anti-abrasion and anti-corrosion resistance in its practical application. Not only PTA treatment on screw flights, also developed the technique of hardness coating of the entire screw surface, so as to bring more benefits to the processors.