Polyamid 66 - NBE1200G30

Categories : PA(Polyamide) /Nylon

Glass fiber 30% reinforced, super high impact. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

HIGH-ACCURACY ROLL-TO-ROLL AUTOMATIC FEED CUTTING MACHINE TRC-350SP

Categories : Foaming Machinery

Double-Axle Synchronous Feed Mechanism: Enhances the production speed and Yield Rate through double-axle synchronous feeding. Well-Designed And Stabilized Bottom Dead-Point Accuracy: Uses the patented Bottom Dead-Point Mechanism exclusively developed by TRURAN to achieve +/-0.005mm of repeated positioning accuracy. High-Accuracy Depth Adjusting Mechanism: Uses high-accuracy mechanism to achieve 0.01mm of fine-tune accuracy (0.001mm is for optional). High-Efficiency Boosting Circuit: Reduces over 30% of power consumption as compared to conventional circuit. Photoelectric Material Flexibility: Uses as the dedicated moving system according to the material characteristics. Unique Material Moving Mechanism: High-stability servo control system is used to avoid contaminating and scratching the material. Automatic Lubrication Mechanism: The entire machine uses Automatic Lubrication Mechanism to reduce daily maintenance work. Waste Recovery Mechanism: The System will recover the waste of cutting automatically to save space, while enhancing the operability.

Polypropylene - PP1200G30

Categories : PP Resin

Glass fiber 30% reinforced. Application: Fan blades, Hand tools, Gardening tools, Sports equipment, Home appliances parts, Medical rehabilitation equipment, O.A. Office components.

Disc Coupling

Categories : Gears

(1) NO-LUBRICATION REQUIRED: No lubricants are needed and no noises or wear and tear produced because there is no sliding or friction. (2) MAINTENANCE-FREE: ”LEAVE IT FOR GOOD AFTER INSTALLATION” It lasts forever as long as is used correctly. (3) LIGHT WEIGHT W/HIGH TORQUE: By operations, it is available in a wide range; it can be made of aluminum alloy to reduce the weight. (4) LARGE OFF-CENTER ALLOWED: With large range of off-centering, it can be used flexibly in all kinds of transmission systems. (5) SUITS HIGH-TEMPERATURE APPLICATIONS: All-metal-pars construct makes it suitable for high temperatures. (6) BACKLASH-FREE: WITH GOOD TORSIONAL RIGIDITY Perfect for axial rotation that requires accuracy and machines with phase-control. (7) CAN BE USED IN EVEN HIGHER SPEEDS: It is highly balanced due to being backlash-free and light weight. (8) EASY TO INSTALL: Comprising small number of pasts and being compact, it can be installed/uninstalled quickly. (9) ROBUST STRUCTURE AND HIGH SAFETY COEFFICIENT: With load stress kept at low standard, it works with very high safety coefficient. (10) AUTOMATIC PROTECTIVE DEVICE: In case of damage, an automatic protective device rotates via pads.

Needle Punching Section

Categories : Hydraulic Punching Machines

A complete needle punching section including feeding system, pre-needle punching machine, finish needle punching machine, edge cutter, and other peripheral equipment. Taylor made complete needle punching line according to customer’s needs leads to great flexibility of production. Wide range of application covers geotextile, car carpet, filtration, mattress, and more.

OVER INJECTION MOLD

Categories : Injection Molds

Over Molding is the process where one material is precision molded over another material, usually rubber (TPE) over plastic, for visual or ergonomic appeal. Very often when the design requires ” soft touch” or waterproofing (IP68), over molding is the manufacturing process that we will use. For over molding success, knowledge of material compatibility is crucial. Our extensive expertise in this field helps assure your end part will have the strong end-application bond and performance that your product success demands. Insert molding can also be combined with over molding using parts made of aluminum, brass, stainless steel, copper, plastic and more.

Primary Packaging–Pharmaceutical - Eye drops - CJU-830 + CJ-500

The liquid production processors design compliances with cGMP of the liquid product guideline. The processors are applicable for low viscosity and volume below 60mL.

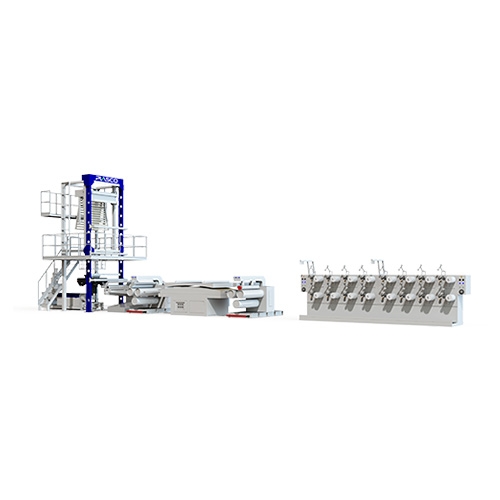

Tying Tape & Twine Extrusion Line (JC-BFY Series)

Categories : Blown Film Extruders

The JC-BFY series tying tape extrusion line by blown film extrusion process is speically designed to produce tying tape, polytwine, twisted twine for light packaging applcation, as well other general packaging and industrial application.

PET Stretch Blow Molding Machine - TEM08M3

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

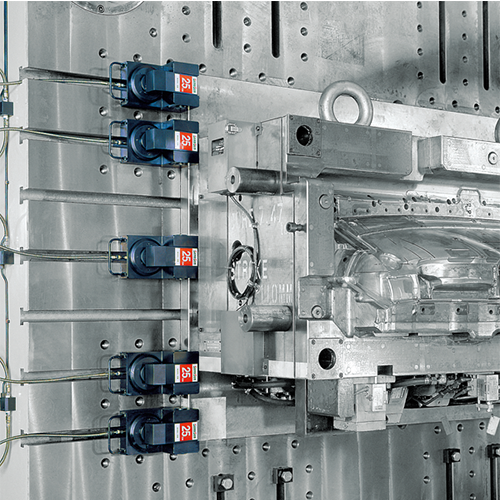

Quick Mold Change System

Categories : Mold Changing Systems

It is an era for making high frequency mold change with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to apply Quick Mold Change System. SAFETY FUNCTION OF SYSTEM Each hydraulic circuit has the function of check and avoiding oil leaking. This system can add pressure automatically when the pressure reduction. Each hydraulic circuit has the function of inspection pressure and can be interlocked with the machine. It adopts the intersecting direction to clamp the mold. There are several functions to avoid operation error.

Hydraulic Clamping Injection Molding Machine (HCV Series)

Categories : Horizontal Injection Molding Machines

• New hydraulic clamping mechanism is with integration high pressure cylinder and prefill valve at top end which is to raise up the locking pressure much faster , also fast speed for mold closing and opening . Whilst , solid mechanical design provides much stronger rigidity of mold platen and ensure the high accuracy of molding products . • Linear transducers for Clamping , Ejection and Injection strokes , accurate and easy in operation . • Adopted the high efficient Japan made servo system ( DAIKIN SUT SYSTEM) which is with pressure transducer to detect and feedback , also the encoder behind motor will calculate and provide accurate oil flow to achieve CLOSE LOOP control . SUT system can provide excellent response time ≦ 0.07sec , repeatability ≦ 1% and linearity ≦ 1% . • With diagonal dual carriage cylinders to enforce the nozzle holding force . Liner rails with ball bearings supports whole injection unit to reduce the mechanical resistant and accurate the injection control. • Digital type back pressure control. • Ion nitrided screw and barrel sets are with long working life .