HomeProductsInverter / Inverter Duty Motor: GFEF Series

Categories : Motors

Foot mounted Insulation class: F class Suitable for general inverter applications Basic speed adjustment Reliable operation function Energy-saving and easy-maintenance

Perforated Bag on Roll Making Machine (Coreless)

Categories : Plastic Bag Making Machines

● Germany made high-sensitivity photo cell device which can catch printing mark correctly. ● When the print is inaccurate position, the machine will stop automatically.

Vertical Plastic and Injection Molding Machine YHL SERIES

Categories : Vertical Injection Molding Machines

- Vertical upright clamping, straight shot structure, simple structure. - The design method of shooting the center shifting element makes the three-sided space more open, and can be applied to the long strip-shaped automobile sealing strip to form a corner or to form a lead product, which makes the forming work easier. - Vertical plastic injection machine, injection system adopts standard and modular design, universal injection molding of various types of inserts, and excellent plastic molding ability. - Vertical rubber injection machine, injection system adopts screw feeding and plunger injection two-stage design, which can adapt to different hardness rubber materials, and rubber injection is stable and accurate. - Optimized design, such as one of the most reliable injection molding equipment for clamping/injection/plasticizing.

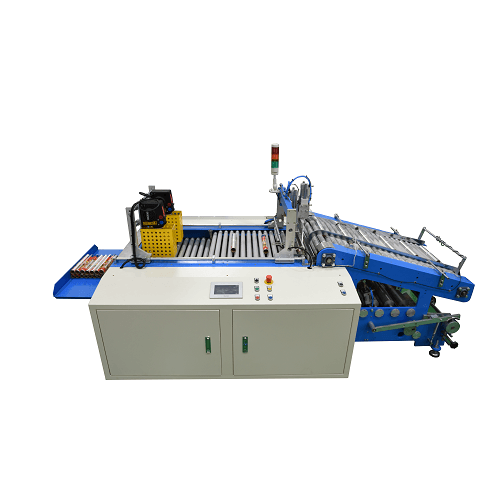

AUTOMATIC SHRINK FILM PACKAGING MACHINE (TPG 50)

Categories : Slitters and Rewinders

Model TPG50, the automatic shrink film packaging machine. A special design for wrap roll products. It can be connected to the back side of rewinding machine as an automatic production line. You can not only make your product refined and protected, but also arrange manpower more effectively. TPG50 is carried 3 conveyors as 3 work areas. It uses conveyors to deliver products to the processing area. You can choose automatic feeding of the material,or feed by detected sensor. As shrinkable films, BOPP, PVC and PE can be used on TPG50. The length of over wrapping film can be set manually or detected by the mark sensor. For packing decoration, you can use printed film; or, equip with a label paper device. The device will insert a piece of label before shrinking. The label will be wrapped inside the film, makes your product eye-catching. The last step, electrostatic device and thermal-wind will perfectly pack your products! Welcome to consult machine with us, we will at your service.

Heat Transfer Film for Metal Materials

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. Heat transfer film is widely used on metal materials, after appopriate surface tratment, most metals are ready to printing. Heat transfer film or thermal film will be perfect solution for PP printingTransfer printed film has many function which direct printing doesn’t have. Using transfer printed film and transfer printed machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

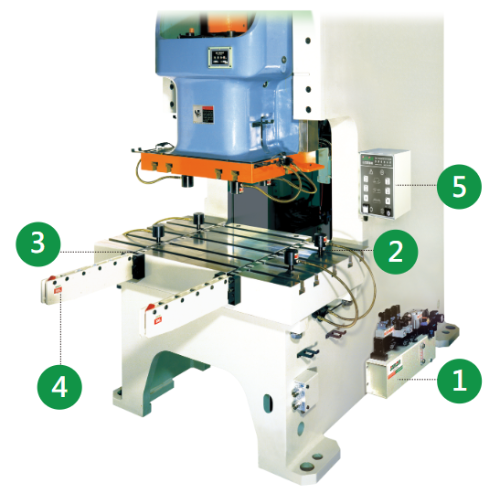

Quick Change Die System

Categories : Mold Changing Systems

It is an era for making high frequency of die changing with multiple patterns and small quantity. In order to save die changing time and ensure operational safety, it is just in time to apply Quick Die Change System. APPLICATION Press & Hydraulic Press Different Automatic Machine & Clamp System

CONTRACT MOLD MANUFACTURE

Categories : Hot Runner Systems

CONTRACT MOLD MANUFACTURE Yomura offers production molds that will be to customer’s facility or a manufacturing location designated. We manufacture molds for almost every major end market for plastics, like, housewares and delicate medical parts, aerospace parts, automotive parts or tiny parts for consumer electronics. All the molds are built to your specification, including type of steel, runner system, gate type, cavity materials and other features specified. Whenever the molds arrive at your facility, they can fit directly to your injection molding machines and are ready for production. ADVANTAGES Early involvement in design phase Ability to provide accurate and quick mold quote Low cost, quick build and high quality A price fully competitive with major mold makers around the global Long life-cycle and low maintenance Reliable delivery schedules Delivery of bug-free molds and ready for production as soon as arrival Complete integrated design and project management services Adapting the latest technology in design and advanced machine tools Ability to communicate quickly and efficiently, and easy to work with Close to superhighway, allowing for quick travel Service centers and international offices are available in major market countries Joint mold making operations with mold makers in other countries bring Yomura closer to the customers PROCESS FOR CONTRACT MOLD MANUFACTURE Customer supplies 3D CAD file to acquire quote Yomura starts the mold order process based on confirmation Yomura sends the 3D full mold design for your review and approval Yomura starts to build the injection mold upon approval Pilot and short production run after mold completion Sample approval Tooling delivery to location specified

Polyamid 6 - NAT7200

Categories : PA(Polyamide) /Nylon

High impact at low temperature, black colored. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

Spindle Servo Motor-SP3 Series

Categories : Motors

SP3 suitable for technical request below 12000RPM and available for customized or high speed type spindle motor.

PET/PC One Stage Injection Blow Molding Machine FS-BT

Categories : Injection Blow Molding Machines

FS-BT-S is equipped with 2-station servo table and side-blow system. After preform injection, the servo table rotates 180 degrees, a servo screw then transfers a neck plate with PETIPC preforms to the side-blow station for blowing bottles. Using side-blow system is available and flexible for a bigger work place, and optional devices; gate trimmer (preform tail cutting device) and product conveyor can easily be mounted inside the machine to go on the automatic production. This model is good for small containers with short cycle time. Jar/wide-mouth bottle available, FS-BT-J has the same benefits of FS-BT-S, but is for wide-mouth jar applications, and it's a stronger machine with higher injection capacity and stronger clamping force. Innovative approach by 2-station machine operation, FS-BT-S/FS-BT-J need less neck cavities, less mold cost, and has a more effective mold width to save the total cost. Mold cost is an important investment in running diversified and various products lines. The tooling'mold cost in our simple and innovative system is the lowest of all.

Kneader Ruder (DAKE-Series)

Categories : Dispersion Kneaders

The Open Kneader With Ruder Is Available With a「Variety Of Blades In Different Shape Design As Well As With Number Of Discharge Methods And Mixing Conditions」, Has Already Achieved Applications Considerable Various Of Industries That Deal With Such High And Medium-Viscosity Materials As Adhesives, Hot-Melt Material、Silicon Rubber、BMC、Ceramics、Fiberglass、Magnetic Compounds、Printing Inks、Tapes、Thermosetting Resins、Food、Cosmetics、Pharmacy Etc.