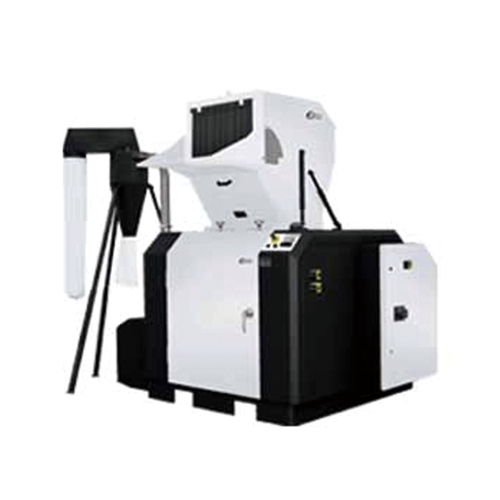

Sound-proof Central Granulators - SG-43

Categories : Granulators

SG-43 series are suitable for centralized recycling of waste and rejected parts form injection, blowing molding and extrusion lines. This series feature compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level ensures low energy consumption.

“Standard” Series SG-23E/30E/36E

Categories : Granulators

SG-23/30E series granulators have no significant differences with the standard model in construction and operability. The granulators feature quick blade change. They are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding and extrusion machines. Staggered blades can easily grab and granulate the materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.

Sound-proof Central Granulators - SG-43-50-70

Categories : Granulators

SG-43 series are suitable for centralized recycling of waste and rejected parts form injection, blowing molding and extrusion lines. This series feature compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level ensures low energy consumption.

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

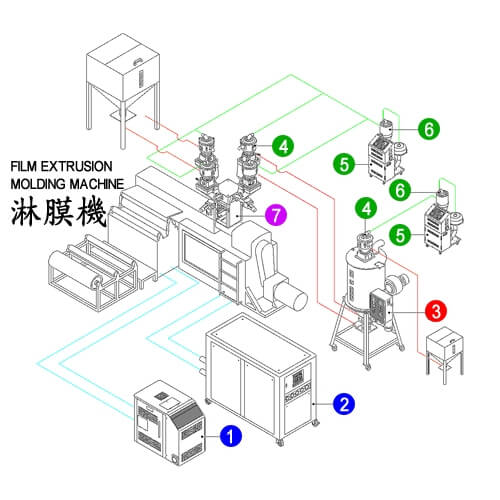

Film Extrusion Molding Machine Auxiliary Solutions

Categories : Assembly Systems

We have a wide range of auxiliary equipment for film extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

PET Fully Electricity Stretch Blow Molding Machine for Jar and Large Containers

Categories : Electric Blow Molding Machines

-Servo-motor technology (preform transfer system – preform stretching – press clamping). -Energy savings. -Quiet. -Faster cycle times. -Reduced downtime and labor. -Optional jar preform auto feed.

All Electric Blow Moulding Machine for 200ml, 500ml Shampoo Bottle

Categories : Electric Blow Molding Machines

All Electric Blow Moulding Machine for 800ml Bottle with view stripe High Efficiency and Eco-Friendly Design The FKI All-Electric HDPE Bottle Making Machine is specifically engineered for producing 200ml and 500ml shampoo bottles from HDPE (High-Density Polyethylene) material. This advanced machine integrates an energy-saving system, drastically reducing power consumption while maintaining high-speed, consistent output. With its fully electric operation, the machine eliminates the need for hydraulic oil, ensuring a cleaner, more sustainable manufacturing environment.

Stretch Blow Molding Machine MIB-SERIES

Categories : Injection Blow Molding Machines

This model of one-stage, three station in ection stretch blow molding machine is made by KAI MEI plastic machinery co. Itd. It has the possibility to economically produce high quality contain ers using various of many kinds of material in PET,PP,PC,TRITAN,PES,etc. and save energy. It lets our customers obtain the most profits with the fast cycle time from this injection stretch blow-molding machine. PROCESSING WITH 3 STATION ROTARY TABLE The process of this machine is by using a rotary disk to cycle three stations. At the first station,there is a high clamping force on the inection mould of this machine to ensure obtaining a good performace quality. At the second station, we assigned a controller to adjust the temperature so that our customers could obtain the best quality bottles. At the third station, it is in process of the stretching and high pressure blowing shape. At the last station,high quality bottles can be easily taken out.

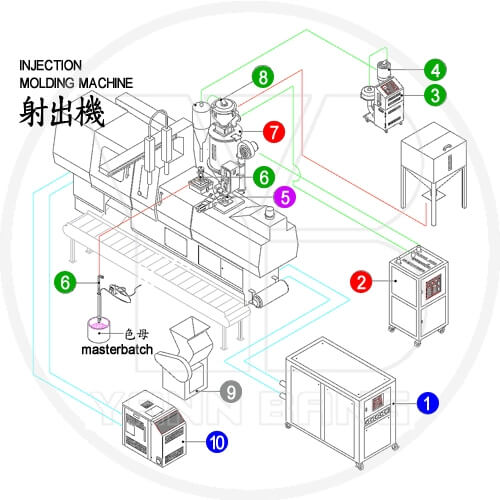

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Vertical Injection Molding Machines

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

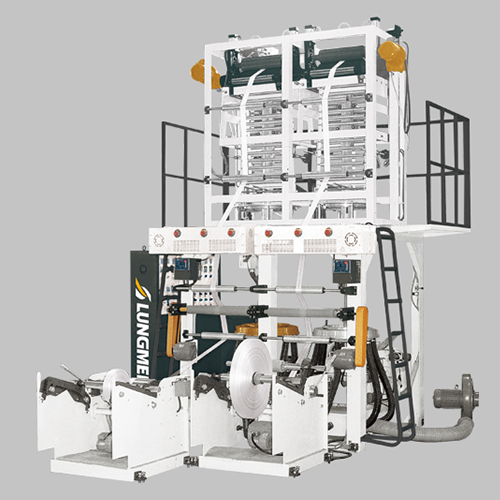

High Speed Twin Die Blown Film Machine

Categories : Blown Film Extruders

Extruder Mono-Layer HDPE/LDPE/mLDPE/PP High Speed Twin Die Blown Film Machine High performance main AC motor with inverter designed for saving energy and minimum maintenance Nip inverter designed for accuracy and reliability High torque gear box with enforced lubrication system to minimize machine down time High quality mixing in screw and barrel delivers excellent homogeneity and high output Designed for producing narrow and thin film

Corona Electrostatic Treater

Categories : Non Woven Production Line

This CORONA ELECTROSTATIC TREATER is used to turn materials such as melt-blown fabric (face mask sheet),non-woven fabric (non-woven sheet) and polymers into electrets. The equipment includes a high-frequency inverter power supply, special electrodes and rollers. Through the mutual control of these components, the electret material can deeply capture the charge energy, and maintaining the polarization for a long period. This equipment can be used for application such as turning melt-blown fabric, non-woven fabric (non-woven fabric) and air filter into electret. It greatly increases the filtration efficiency of the filter material by capturing tiny particle which is smaller than filter density. More importantly, this CORONA ELECTROSTATIC TREATER helps melt blown fabric increase 45~65% of filtration efficiency and turns it to the most important layer for medical face mask such as N95, KN95 etc. to reduce infected by corona virus COVID-19. Note: An electret is a material that almost remains electric polarization permanently and is able to generate an electric field in the surrounding area. The electret strength will last longer when corona electrostatic charges deeply by high voltage and frequency.

Mini Type Blown Film Machine

Categories : Blown Film Extruders

Designed for T-Shirt bag and flat bag production Small occupancy of space Simple, flexible and economic operation High output and saving energy Also can work with LDPE resin if changing air ring Film thickness HDPE 0.008~0.06 mm