Toggle Energy Saving Injection Molding Machine Servo 90E to Servo 570E

Categories : Horizontal Injection Molding Machines

● Effective Energy Saving Unit ● Outstanding Hydraulics ● ASE Servo Pump

ATOP- Horizontal Plunger Type Injection Molding Machine

Categories : Horizontal Injection Molding Machines

● New design patent-IPIS (Interchangeable Plunger Injection System). ● Plunger Type Injection can highly save runner resin. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Intelligent program controller makes injection easier. ● The shortest injection molding machine. ● Precise energy-saving hydraulic system.

Hydraulic Servo Energy Saving System

Categories : Pumps

Pioneer products that lead the plastics machinery industry to energy-saving, green-environmental protection.

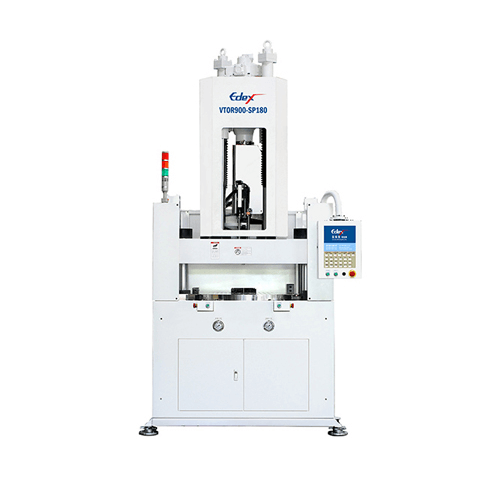

VTOR- Vertical Rotary Injection Molding Machine

Categories : Automatic Injection Molding Machine

● The smallest rotary table design, max mold diameter. ● Suits for Plunger type injection or screw type injection system. ● Patented active bypass auxiliary plasticization system design. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Safety light curtains protection. ● Intelligent program controller makes injection easier. ● The lowest table height injection molding machine. ● Precise energy-saving hydraulic system.

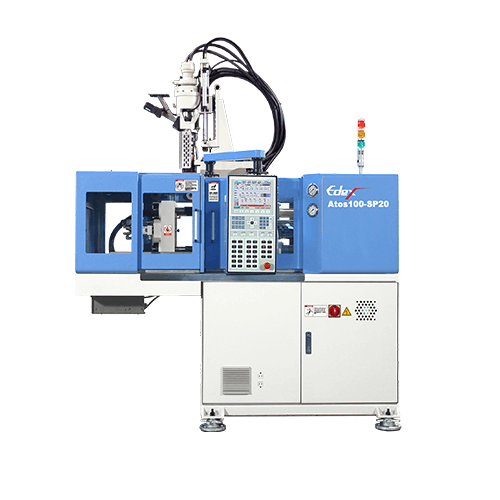

Atos- Horizontal Parting Line Plunger Type Injection Molding Machine

Categories : Horizontal Injection Molding Machines

● Without the sprue, it saves a lot runner resin weight. ● Produce precise micro injection products. ● Products with multi cavities can be highly concentrated to the center. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Intelligent program controller makes injection easier. ● The shortest injection molding machine ● Precise energy-saving hydraulic system.

Pressure Forming + Shape Cutting + Auto Counting Stacking SL-1220A + SL-520

Categories : Vacuum Forming Machines

Flexible package solutions for various budgets and production needs. Fine processing competence fit for all standard and few specific plastics. Cold forming under high pressure load for high capacity and low cost. A cut of labor and waste via direct retrieval of plastic waste Low power consumption due to 30% saving energy and 40% compressed air cutting. A central control unit for easy operation and handy maintenance. • Rich experiences in package equipment with a tailor-made solution for you