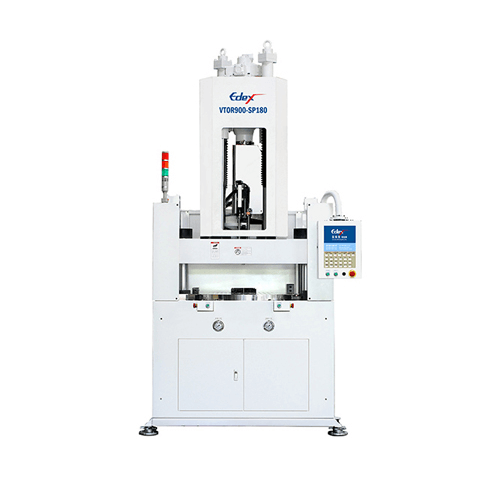

VTOR- Vertical Rotary Injection Molding Machine

Categories : Automatic Injection Molding Machine

● The smallest rotary table design, max mold diameter. ● Suits for Plunger type injection or screw type injection system. ● Patented active bypass auxiliary plasticization system design. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Safety light curtains protection. ● Intelligent program controller makes injection easier. ● The lowest table height injection molding machine. ● Precise energy-saving hydraulic system.

VTOZ- Vertical Screw Type Injection Molding Machine

Categories : Automatic Injection Molding Machine

● Patented interchangeable 3-in-1 modular slide table design. ● Patented none-side-force injection unit design. ● Patented active bypass auxiliary plasticization system design. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Dual protection of safety door and safety light curtains. ● Intelligent program controller makes injection easier. ● The lowest table height injection molding machine. ● Precise energy-saving hydraulic system.

Double Toggle Injection Molding Machine (SMV Series)

Categories : Horizontal Injection Molding Machines

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Multi steps injection pressure and speedcontrol. • Steel bushes have a hardness of HV800 for wear resistances. • Auto-lubrication system is provided to assure the constant lubrication of the toggle mechanism • Multi-stroke hydraulic ejector ensures positive ejection of the product and enables unmanned production with or without the use of a robotic arm. • Differential hydraulic circuit shortens cycle time and saves energy. • Low pressure mold protection system was used to avoid mold damage or excessive wear.

HX Series-100/200/300

Categories : Industrial Robots

Energy saving, light design, and the special selection of raw materials reduce the energy consumption of the operation.

All Electric Machine With SPARK Series

Categories : Automatic Injection Molding Machine

Features: Combining ultra-thin high speed and ultra-thick low speed Revolution round template design with Japanese super rigid frame Super high-speed intelligent computer controller With Japanese screw design, excellent performance All-electric machine vs. Hydraulic machine More environmentally friendly → Reduce the configuration of cooling water circulation system More energy saving → No need high-watt electric source. More environmental cleanness → No oil leakage concern and no hydraulic oil consumption. More quiet → No high speed sound driven by oil pump. Easier to execute the machine compounding action → difficult for hydraulic machines. More sensitive for mold low pressure protection → avoid damage to mold.

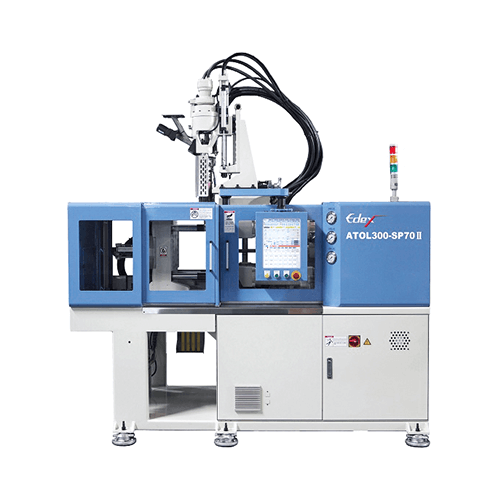

ATOL- Horizontal Multi-color/resin Injection Molding Machine

● Single, dual, triple color/resin in one machine. ● Suits for Plunger type injection or screw type injection system. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial platen durable for 30 years. ● Intelligent program controller makes injection easier. ● The shortest injection molding machine. ● Precise energy-saving hydraulic system.

PET Preform Neck Crystallization Machine - CR Series

Categories : Crystallizing Machines

● Economic and energy saving, compare with other crystallized machine help save energy. ● Through star wheel, stable and smooth to transport system.

PET Preform Neck Crystallization Machine - CR6K

Categories : Crystallizing Machines

Economic and energy saving compare with other crystallized machines.It can save up to 50% of energy. Through star wheel, stable and smooth to transport system.

PET Stretch Blow Molding Machine - TEM08M3

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

CE Energy efficiency Servo Press

Categories : Compression Molding Machines

CE Energy efficiency Servo Press :The servo motor system uses green electric power, which can save 80% of electricity usage, and precisely adjusts the pressure direction and position with high repeatability, reducing the defective rate of products. Oil-free system is suitable for low-pollution working environment. Provide mold preheating system to shorten the hot press molding time.

Vertical Electric Injection Molding Machine-YE-50V

Categories : Vertical Injection Molding Machines

A number of patented electric injection device Precision electric injection function Precision electric metering function Electric pedestal does not slide function Energy-saving hydraulic servo mold clamping function Accurate low pressure off mode protection function Energy-saving hydraulic servo thimble function Template rust plating processing Template parallelism fine tuning function Template low-top design With 8 T-groove, easy to fix the mold Thick template with high tensile guide posts Configuration template guide column anti-drip bumper sleeve Configure mechanical closing safety bars Configure mechanical shut-off safety electrical protection Open all the safety gates to stop the design Configuration key type safety door safety switch Configuration rail horizontal operation safety gate design Injection device can be flipped to maintain the factory accuracy to reduce the height of the handling method Injection closed loop feedback function Holding pressure switching point accuracy of 0.01mm Packing pressure accuracy of up to 0.1% High-speed rigid filling, to eliminate floating phenomenon Prevent the drawing function A variety of peripheral equipment chain function Equipped with peripheral equipment power outlet With robot centralized terminal block Hopper holder moving function Equipped with resin feed tube holder Equipped with adjustable height white iron trough Equipped with a perspective control water divider Equipped with cooling water quick connector The machine is neat and without any pipe exposure Than the same level of oil-saving 25% to 60% Than the same level oil machine to save cooling water 70% Equipped with 10.4 "color touch screen PID automatic temperature adjustment function Japan's Mitsubishi control system Equipped with wear-resistant material pipe

ULTRA LOW ENERGY DRYER

Categories : Dryers and Dehumidifiers For Plastic Materials

The first ULTRA Low Energy Dryer for plastics. Ultra-low kW energy usage - fast ROI and savings for a lifetime. Drying costs so low, it’s almost free Energy efficient unique vacuum drying technology Faster drying, faster start-ups, minimal maintenance