-

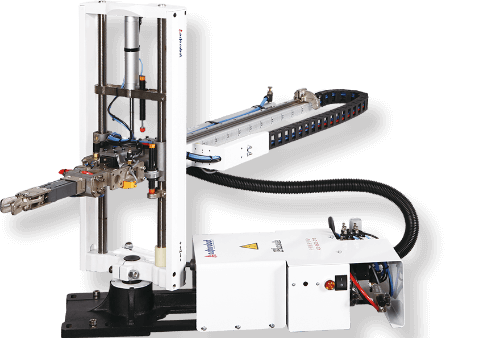

Document management system installed for effective management of arm tooling

- Free encoding functions / 3D display showing parameters for the programmed stacking motion

- User-friendly encoding

- Built-in PLC software (from Ladder Software) / an easy-to-use teach pendant

|

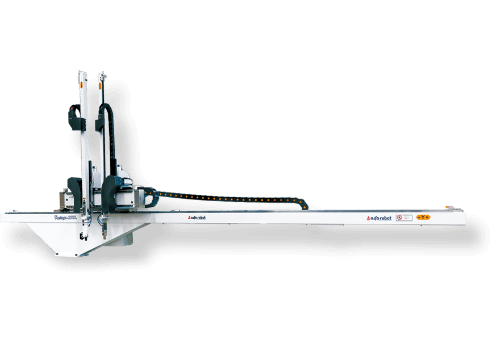

ITEM |

HX-100 |

HX-200 |

HX-300 |

|

Molding Machine Size (ton) |

III/V |

III/V |

III/V |

|

A. Full Length |

2080/2160 |

2420/2500 |

2630/2730 |

|

B. Full Width |

1425 |

1425 |

1525 |

|

C. Height of Main Arm |

1415 |

1475 |

1645 |

|

D. Height of Sub Arm |

X/1415 |

X/1475 |

X/1645 |

|

E. Max. Radius of Product Handled |

322 |

||

|

F. Min. Distance b/w the Arms |

X/60 |

X/60 |

X/60 |

|

G. Standby Position of Main Arm |

100 |

100 |

150 |

|

H. Standby Position of Sub Arm |

X/133 |

X/133 |

X/183 |

|

I. Distance b/w Main Arm and Base |

110/245 |

110/245 |

110/245 |

|

J. Distance b/w Sub Arm and Base |

X/95 |

X/95 |

X/95 |

|

K. Max. Demolding Stroke |

780 |

780 |

880 |

|

X. Traverse Stroke |

1030 |

1370 |

1500 |

|

U. Height of Base |

275 |

325 |

|

|

Zm. Vertical Stroke of Main Arm |

700 |

800 |

900 |

|

Zs. Verticcal Stroke of Sub Arm |

X/750 |

X/850 |

X/950 |