KET Series All Electric Injection Machine KET-40 (STANDARD)

Categories : Vertical Injection Molding Machines

Discover the power of our Vertical Injection Molding Machine, delivering low noise and high efficiency. Experience the benefits of green energy with water and power-saving features

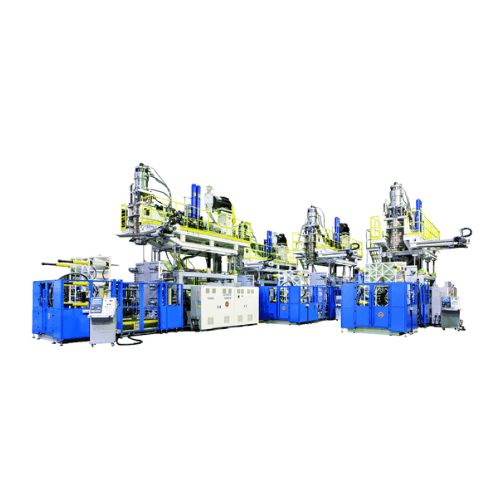

Hybrid Type Extrusion Blow Molding Machine

Categories : Electric Blow Molding Machines

In order to satisfy the purchase demand for power-saving and durable blow molding machine, Chia Ming researches and develops energy saving and practical servo hydraulic electric series (hybrid blow molding machine). It has characteristics of speedy positioning, accuracy and energy saving of the fully electric type, and also keeps the characteristics of high thrust of hydraulic oil structure. Also, the cost is lower than fully electric types while keeping the same characteristics.

Fully Electric Extrusion Blow Molding Machine - Dual Diehead & Single Station

Categories : Horizontal Blow Molding Machines

Full electric movement, energy saving 15%~40%. Fully Electric Extrusion Blow Molding Machine - Dual Diehead & Single Station

Continuous Extrusion Blow Molding Machine-Single Station

Categories : Electric Blow Molding Machines

Energy Saving. Using one hybrid servo motor to control all machine actions. Power consumption is less than a general hydraulic machine by 20~45%, easy to reach energy saving and carbon reduction goals. Servo Hydraulic and Electric Power System: Accords actual operation condition to carry on the automatic velocity modulation, reduces the energy loss of auxiliary construction section greatly, and tallies with recent modern energy conserving and environmental protection. Reduces the system response time, and reaches the quality requirement of high accuracy products.

Solvent-less & Solvent-base Combi Laminating Machine(WDSL Series)

Categories : Industrial Lamination

For the solvent-free lamination, WORLDLY launches solvent-less & solvent-base combi laminating machine WDSL series. The unwinder and rewinder are adopted with a double shaft turret type with automatic splicing system, which can continue splicing without stopping the machine. This also greatly enhances the work efficiency. Moreover, the manipulation is much easier and simple with the PLC digital control system and touchable human-machine interface. Solvent-less & solvent-base combi laminating machine WDSL series is the leading popular machines for solvent-free. It has higher compound speed in order to increase productivity. And, there is no wasted costs caused by the solvent evaporation. Also, the coating thickness is very thin with 100% solid ingredient which can reduce a lot of cost. The production won't produce solvent evaporation and there is no solvent residue. It all conforms to food safety regulations. Meanwhile, there's no need for drying chamber which can save energy. The solvent-less & solvent-base combi laminating machine can be ordered from solvent-base lamination, solvent-less lamination, or solvent-base & solvent-less lamination which can accomplish three-layer lamination depends on the customer's need, and the machine itself can be shorten to save space for additional use which can make a significantly cost reduction.

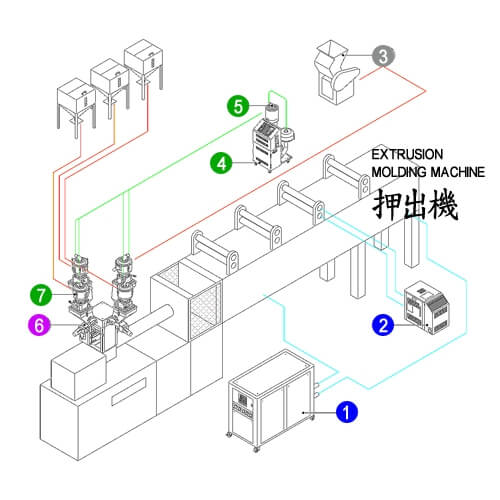

Extrusion Molding Machine Plastic Auxiliary Solutions

Categories : Assembly Systems

We are capable of offerring a wide range of auxiliary equipment specificaly for extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

High Degree Water-type Mold Temperature Controller

Categories : Control Equipment

Economic and advanced design for high degree is your new choice. Water-type mold temperature controller (High Degree) do not pollute environment with oil gas that is the best choice for electronics, medical and cosmetic packing industries where strictly require better working environment. When oil-type model cannot satisfy for your need, you should change to water compression one. By direct supply method, it will not transform to steam even the temperature up to 160℃. Heat up faster, long machine life, high stability, precise control within ±0.3℃, and energy save for you. Precise temperature control and high stability control by 0.1℃ as a unit to display. The inaccuracy rate below ±0.3℃. Perfect for any precise requirement such as electronics industry. Heat-insulated design extend operating lifetime. PID temperature controller. Excellent overheat security protecting device. SSR relay control for durability. Unique design to prevent water leakage and pollution when mold is changed.

Accumulator Head Blow Moulding Machine for Table Top

Categories : Extrusion Blow Molding Machines

Compact design with less footprint Energy saving with high/low pressure circuit ONE HMI for total operation function Remote access for support diagnosis and troubleshooting Product range up to 22kgs shot weight

ULTRASONIC LACE SEWING MACHINE KS-85

Categories : Cutting Machines

1. Use ultrasonic energy to cut , weld, seal, seam, hole, emboss, stitch, slit, form, color transfer & fold and other fabric processing functions, can be cut and sealed at once! 2. The width of the pattern is 23mm, 48mm, 70mm.

Ultrasonic Plastic Welder KWD2620-N

Categories : Automatic Welding Machine

Automatic frequency self-checking at startup. Automatic tuning (frequency control). Resonance frequency compensation during the welding cycle. Full-Bridge IGBT module drives the transducer. PWM (Pulse Width Modulation) amplitude control, linear adjustment from 50%~100%. PWM (Pulse Width Modulation) startup vibration (8 selective ramp start-up settings). Protection against ultrasonic frequency deviation, high voltage and over current. External control box display ultrasonic frequency and welding energy. Frequency compensation as horn’s working temperature increase. Abnormal welding alarm. RS485 communication interface. 3 welding modes:Time mode/ Trigger pressure mode/ Energy mode (target & interval setting). Monitor and transmit each welding parameters and status (requires remove the control box and connect to the computer).

CH- Plasma - J

Categories : Surface Treatment Equipment

Plasma Treater Country of Origin:Taiwan Plasma treaters produce plasma surface treating to promote the adhesion of inks, adhesives, coatings, sealants & paints. Manufacturers integrate in-line plasma treatment equipment to enhance adhesion on plastics, composites, metals & glass surfaces. The plasma pretreatment process cleans, etches, & functionalizes surfaces to activate bonding sites by increasing wettability & surface energy.

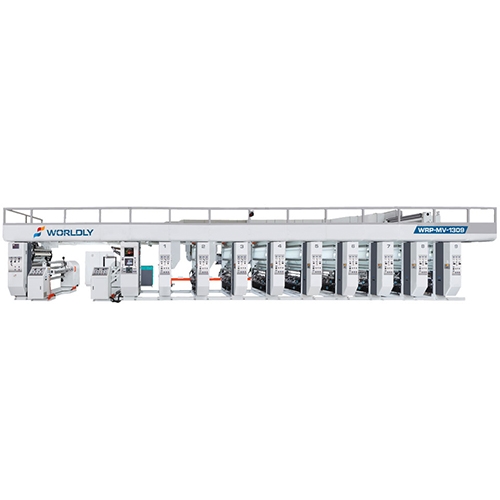

High Productivity Rotogravure Printing Machine(WRP-MV Series)

Categories : Rotogravure Printing Machines

Worldly company has good experience and technology development in new rotogravure machine over the years. The printing press equipment with powerful combination of central control system, and ease for operation. Simply and easily function and control parameter display on the human-machine interface touch screen, synchronized with PLC control system, also automatic alarm system provide the most efficient printing management for operators and leads to reduced default rates and less waste. Otherwise the exhaust recycle system can recycle the air up to 75% energy,The design leads to high productivity, lowers production costs, and provides a competitive advantage.