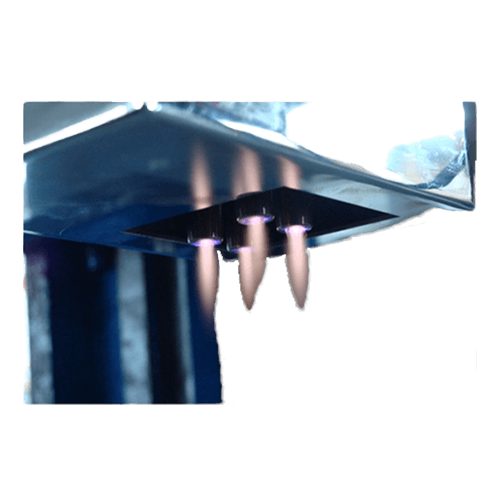

Plasma - J4

Categories : Surface Treatment Equipment

Plasma Treater Country of Origin:Taiwan Plasma treaters produce plasma surface treating to promote the adhesion of inks, adhesives, coatings, sealants & paints. Manufacturers integrate in-line plasma treatment equipment to enhance adhesion on plastics, composites, metals & glass surfaces. The plasma pretreatment process cleans, etches, & functionalizes surfaces to activate bonding sites by increasing wettability & surface energy.

Constant Water Chiller (YCWP)

Categories : Cooling Equipment / Industrial Chillers

Different to traditional water chillers with unstable temperature degree and unreliable compressor troubles, YCWP as a high-quality water chiller can be set by your required degree precisely and keep it steadily. The advantages ensure your product in high quality and improve process capability. Also save more power energy for you! Mold’s cooling temperature controlling setting within ±1 ℃ to ensure high-quality products and increase high performance. By unique constant design, YCWP save more energy and extend machine life. Equipped with high-efficiency condenser able to work in high heat conduction and reduce 35% of unit size for space save. Use imported well-known compressor. Large models adopt dual compressors with dual cooling system that work independently. When one breaks down, the system will keep working and keeps production line smoothly. Use P.I.D. temperature controller, error Indicators, digital display controller and more safety protection devices. User-friendly setting and smart error report for your productive more efficient.

ULTRASONIC LACE SEWING MACHINE KS-72

1. Use ultrasonic energy to cut , weld, seal, seam, hole, emboss, stitch, slit, form, color transfer & fold 2. No need for traditional needle threading. 3. Processing without burrs, wrinkles, shrinkage。 4. Can work continuously for mass production, can work curves; easy to change rollers. 5. Can print color on the lace with colored paper 6. Accurate & durable alloy roller are designed by computer aid &made with sculptural molds 7. No smoke, no sparks, avoid high frequency and heat cutting danger 8. No preheating, processing can be done at the start, easy to operate, low labor costs 9. Thousand of pattern roller designs available

ULTRASONIC LACE SEWING MACHINE KS-82

Categories : Cutting Machines

1. Use ultrasonic energy to cut , weld, seal, seam, hole, emboss, stitch, slit, form, color transfer & fold and other fabric processing functions, can be cut and sealed at once! 2. The width of the pattern is 23mm, 48mm, 70mm

High Degree Water-type Mold Temperature Controller

Categories : Control Equipment

Economic and advanced design for high degree is your new choice. Water-type mold temperature controller (High Degree) do not pollute environment with oil gas that is the best choice for electronics, medical and cosmetic packing industries where strictly require better working environment. When oil-type model cannot satisfy for your need, you should change to water compression one. By direct supply method, it will not transform to steam even the temperature up to 160℃. Heat up faster, long machine life, high stability, precise control within ±0.3℃, and energy save for you. Precise temperature control and high stability control by 0.1℃ as a unit to display. The inaccuracy rate below ±0.3℃. Perfect for any precise requirement such as electronics industry. Heat-insulated design extend operating lifetime. PID temperature controller. Excellent overheat security protecting device. SSR relay control for durability. Unique design to prevent water leakage and pollution when mold is changed.

Insulation Plus Ceramic Band Heaters

Categories : Heating Equipment

Saving in energy up to 30 % Reduced wattage of heater More uniform heating Less down time increases productivity Reduced preheating time of machine Heater cost is recovered in shorter time Cool working atmosphere for operator Arico

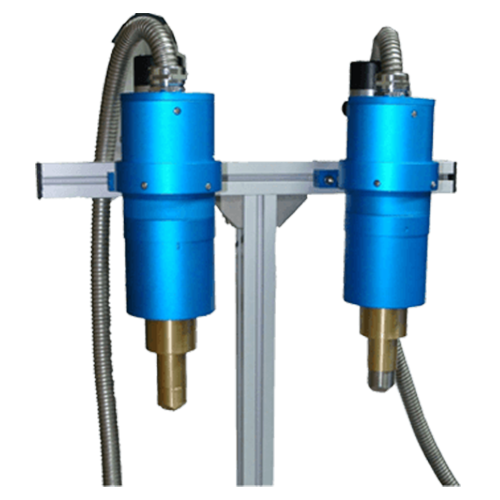

CH- Plasma - PJ

Categories : Surface Treatment Equipment

Plasma Treater Country of Origin:Taiwan Plasma treaters produce plasma surface treating to promote the adhesion of inks, adhesives, coatings, sealants & paints. Manufacturers integrate in-line plasma treatment equipment to enhance adhesion on plastics, composites, metals & glass surfaces. The plasma pretreatment process cleans, etches, & functionalizes surfaces to activate bonding sites by increasing wettability & surface energy.

Plasma - JR

Categories : Surface Treatment Equipment

Applied to 30mm width or tube inside surface treatment. Detail specification contact please. Plasma treaters produce plasma surface treating to promote the adhesion of inks, adhesives, coatings, sealants & paints. Manufacturers integrate in-line plasma treatment equipment to enhance adhesion on plastics, composites, metals & glass surfaces. The plasma pretreatment process cleans, etches, & functionalizes surfaces to activate bonding sites by increasing wettability & surface energy.

Oven Dryer (YBO)

Categories : Dryers and Dehumidifiers For Plastic Materials

The Oven Dryer is a compact, convenient drying equipment which can dry more than one type of resin at the same. For plastics use, it can be used for annealing and product testing after molding. It can also dry electric motor and parts, electroplating, pharmaceutical, paint, printing, agricultural and food. (grain, garlic, tea, and etc.) Powerful, heated air flow system and unique air circuit are designed for evenly temperature control and the best baking quality. The oven dryer has stainless steel trays in which you can place your resins or material to be dried. Hot air recycling system is durable and energy saving. Equipped with 24-hour-timer which can be set in advance to operate the oven dryer.

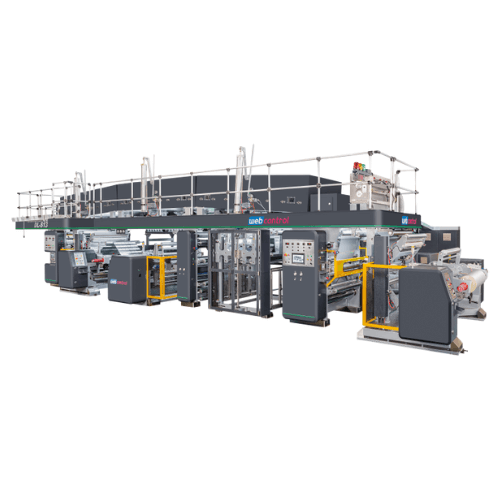

Dry Laminating Machine Shafted Type DL-1000/1300

Categories : Industrial Lamination

This machine is for the Laminating process that uses a solvent-based adhesive. Reliable tension control with a mature lamination process able to make high-end products such as retort, sterilize and medical pouches. The gravure coating station allows high precision and consistency in coating weight. An efficient drying tunnel has high performance in vaporizing solvent completely to keep the product safe. Various options of heating solutions for drying tunnels are available. The energy-saving system is an option to help decrease carbon footprint and the cost of production

Industrial Ultrasonic Humidifier KT-200/KT-300/KT-400/KT-600/~~KT-2400

1.By Ultrasonic, only mist given, no water spots. 2.Energy efficient, low power consumption. 3.Easy installation and operation. 4.With humidity control. 5.Automatic water filling, safety shut-off when no water. 6.Easy to maintain and clean. 7.Use clean and cool water, give the suitable humidity to environment. 8.Ultraquiet-Noseless operation. 9.Adjustable nozzle for any required angles. 10.Widely use in Hospital, Pet Shop, Laboratory, Factory, etc...