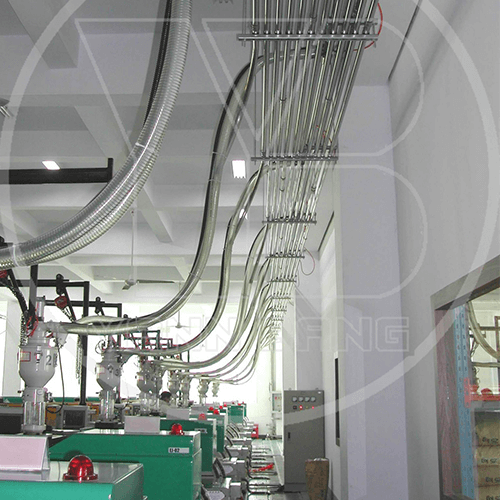

Central Material Conveying System

Categories : Loading and Conveying Machines

Our central vaccum conveying system also called centralized pneumatic supply system. It can be completely customized to your plastics processing to fullfill the target of continuous operation without downtimes. Central Material Conveying System A central conveying system can control 30 sets of molding machines at the same time and return on your investment in 2-3 years. 1. Better company image 2. Greater productivity 3. Lower cost 4. Better energy efficiency 5. Less material waste and pollution during the conveying process 6. Better working environment 7. Less noise due to the separation of the blowers from the working place

Water Chiller (YBW)

Categories : Cooling Equipment / Industrial Chillers

Water Chiller (YBW ) Use the latest European, American or Japanese compressor, available in single and double compressors. The compressors of the double-compressor model can either run alone or together. High-efficient shell-pipe condenser which has heat-transmission function can save energy. Well-designed safety protection. It is also equipped with a digital temperature display indicator and abnormal warning indicators for the long lasting. Applied Machinery: oil temperature, ultrasonic ,high frequency machine/injection /extrusion/blow molding machine

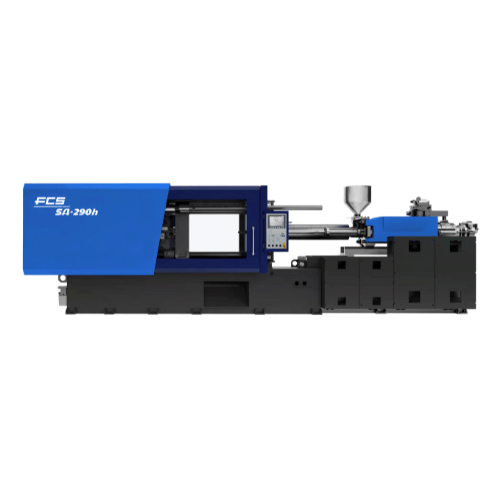

IMM for PET Blood Collection Tubes (SA-h PET Series)

Categories : Toggle Clamping Injection Molding Machines

It is a newly-released servo hydraulic energy-saving model with outward toggle clamping unit, which is specialized for PET tube. With clamping force ranging from 220 tons to 290 tons.

Corona Treater -T Series / For Blown Film Line

Categories : Blown Film Extruders

Corona treater is a surface modification technique for adhesion improving treatment and increase dyne level. It uses a low temperature corona discharge plasma to impart changes in the properties of a surface. Materials such as plastics, cloth, or paper may be passed through the corona plasma curtain in order to change the surface energy of the material. All materials have an inherent surface energy. Surface treatment systems are available for virtually any surface format including dimensional objects, sheets and roll goods that are handled in a web format. Corona treatment is a widely used surface treatment method in the plastic film, extrusion, and converting industries. It is also known as plastic surface treater, surface corona treater, air plasma, corona discharge treatment, corona treating, Corona-discharge Plastic Surface Treatment Equipment, corona treatment machine, corona treatment device and corona treatment. Application Extrusion: .Blown film extrusion / Blown film machine / ABA co-extrusion / Inflation machine .Cast film / sheet extrusion / Extrusion coating / coating lamination / Extrusion lamination / tandem extrusion lamination Printing: .Inline Printing press / printing machine / Rotogravure printing machines / woven bag printing / label printing / Solvent printing / water base printing / Flexo printing / T shirt bag printing Converting .Slitting rewinder / coating / wet lamination / dry lamination / hot lamination / solventless lamination / Rotogravure coating machines /gluing / bonding / tandem lamination Model CH-800S / CH-1000S / CH-1200S / CH-1500S / CH-2000S / CH-3000S / CH-5000S CH-800T / CH-1000T / CH-1200T / CH-1500T / CH-2000T / CH-2KT CH-3000T / CH-5000T / CH-8000T CH-3KT / CH-5KT / CH-8KT / CH-10KT / CH-12KT / CH-15KT / CH-20KT CH-3KD / CH-5KD / CH-8KD / CH-10KD / CH-12KD / CH-15KD / CH-20KD Substrate material HDPE, LDPE, LLDPE, MLLDPE, PET, PVC, PP, OPP, CPP, BOPP, PI, PS, PC, EVA, Nylon, PTFE, PU, TPO, TPE, TPO, Bio degradable , Biodegradable, Bio-degradable, Stretch film PE woven, PP woven Hollow profile sheet, corrugated sheet, Cartonplast, Polyflute, Coroplast , FlutePlast, IntePro, Proplex, Correx, Twinplast, Corriflute, Corflute Metalized film, FPC, Foil, copper foil, electrodepositedcopperfoil, CCL Non woven, Melt blown, Fabric, textile

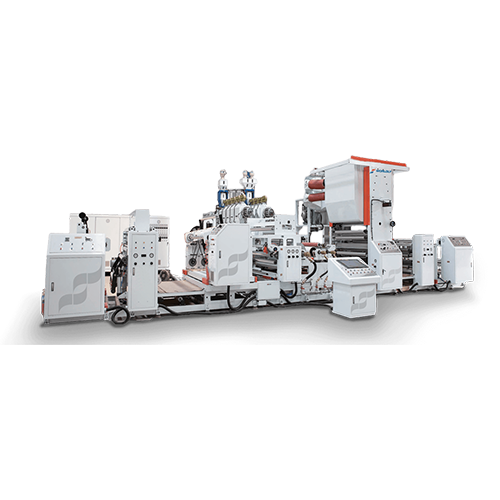

Co-extrusion Coating & Laminating Machine (WCL Series)

Categories : Extrusion Coating Machines

In this fast changing packaging market the multi-layer laminates demand has increased. The Co-extrusion machine allows to use two kinds resin or more by two or more extrusion units to create multi-function extrusion layers. The variety of resin after melted and go through the feed block then join into the T-die. The side screw has corrosion resistance treatment. It’s fine to work with acid copolymer resin, such as EVA, EAA, EMAA and Surlyn etc. The barrel heated by ceramic heater to ensure more energy saving and short start up time. Worldly also developed the exclusive extrusion output control system with Germany leading dosing system company. So it provides very accuracy and stable output and coating gauge control during the production. It can save more material especially for long run job. The high speed H series version of the rewinding splicer adopted with tracking roller device. It provides two kinds gap & contact winding mode and gives uniform and perfectly straight finished winding during high speed running. Also the taper tension can proper control the winding from the beginning roll. So it can reduce the wastage and avoid the wrinkle generate at the inner roll.

ULTRASONIC LACE SEWING MACHINE KS-72

1. Use ultrasonic energy to cut , weld, seal, seam, hole, emboss, stitch, slit, form, color transfer & fold 2. No need for traditional needle threading. 3. Processing without burrs, wrinkles, shrinkage。 4. Can work continuously for mass production, can work curves; easy to change rollers. 5. Can print color on the lace with colored paper 6. Accurate & durable alloy roller are designed by computer aid &made with sculptural molds 7. No smoke, no sparks, avoid high frequency and heat cutting danger 8. No preheating, processing can be done at the start, easy to operate, low labor costs 9. Thousand of pattern roller designs available

Industrial Ultrasonic Humidifier KT-200/KT-300/KT-400/KT-600/~~KT-2400

1.By Ultrasonic, only mist given, no water spots. 2.Energy efficient, low power consumption. 3.Easy installation and operation. 4.With humidity control. 5.Automatic water filling, safety shut-off when no water. 6.Easy to maintain and clean. 7.Use clean and cool water, give the suitable humidity to environment. 8.Ultraquiet-Noseless operation. 9.Adjustable nozzle for any required angles. 10.Widely use in Hospital, Pet Shop, Laboratory, Factory, etc...

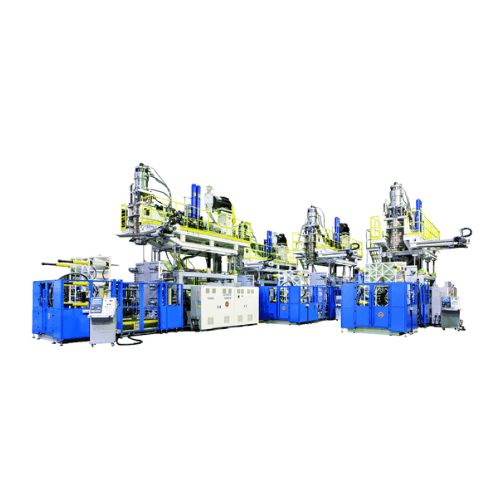

Accumulator Head Blow Moulding Machine for Table Top

Categories : Extrusion Blow Molding Machines

Compact design with less footprint Energy saving with high/low pressure circuit ONE HMI for total operation function Remote access for support diagnosis and troubleshooting Product range up to 22kgs shot weight

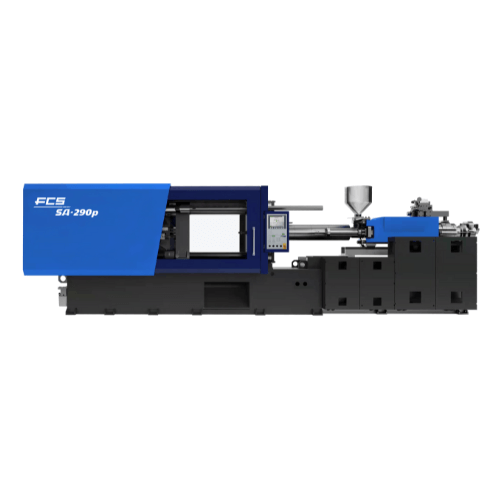

High-Speed Injection Molding Machine (SA-p Series)

Categories : Toggle Clamping Injection Molding Machines

It is a newly-released servo hydraulic energy-saving model with outward toggle clamping unit, especially suitable for producing bucket containers. With clamping force ranging from 220 tons to 1,000 tons.

ULTRASONIC WIDER LACE SEWING MACHINE KS-200A

1. Use ultrasonic energy to cut , weld, seal, seam, hole, emboss, stitch, slit, form, color transfer & fold 2. No need for traditional needle threading. 3. Processing without burrs, wrinkles, shrinkage。 4. Can work continuously for mass production, can work curves; easy to change rollers. 5. Can print color on the lace with colored paper 6. Accurate & durable alloy roller are designed by computer aid &made with sculptural molds 7. No smoke, no sparks, avoid high frequency and heat cutting danger 8. No preheating, processing can be done at the start, easy to operate, low labor costs 9. Thousand of pattern roller designs available 10. Max. working width is 198mm. 11. Using auto tuning Ultrasonic system 12. Overload protection to avoid the ultrasonic system damaging 13. With frequency display to be easily observe the working condition of machine

High Degree Water-type Mold Temperature Controller

Categories : Control Equipment

Economic and advanced design for high degree is your new choice. Water-type mold temperature controller (High Degree) do not pollute environment with oil gas that is the best choice for electronics, medical and cosmetic packing industries where strictly require better working environment. When oil-type model cannot satisfy for your need, you should change to water compression one. By direct supply method, it will not transform to steam even the temperature up to 160℃. Heat up faster, long machine life, high stability, precise control within ±0.3℃, and energy save for you. Precise temperature control and high stability control by 0.1℃ as a unit to display. The inaccuracy rate below ±0.3℃. Perfect for any precise requirement such as electronics industry. Heat-insulated design extend operating lifetime. PID temperature controller. Excellent overheat security protecting device. SSR relay control for durability. Unique design to prevent water leakage and pollution when mold is changed.

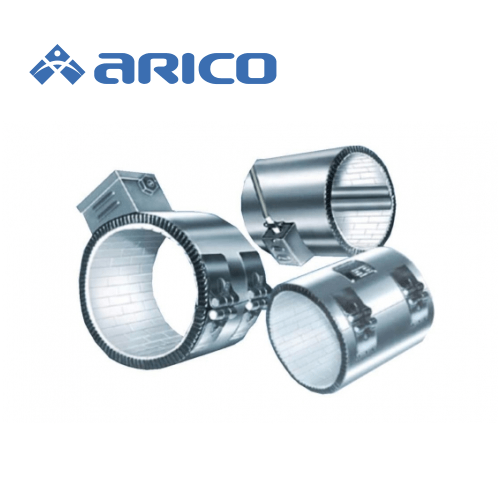

Ceramic Band Heater

Categories : Heating Equipment

ARICO|Customed Ceramic Band Heater Manufacturer Arico is a global customed Ceramic Band Heater manufacturer and supplier, dedicated to improving the thermal insulation, energy saving, service life, durability, ease of installation of Ceramic Band Heater. Mainly providing to India, the United States, China, Thailand, Vietnam, Israel markets at a reasonable price. Thermal insulation Conserves energy Minimum heat loss Easy installation Uniform temperature Better heater life Can be manufactured to your specification Various types of construction & terminations