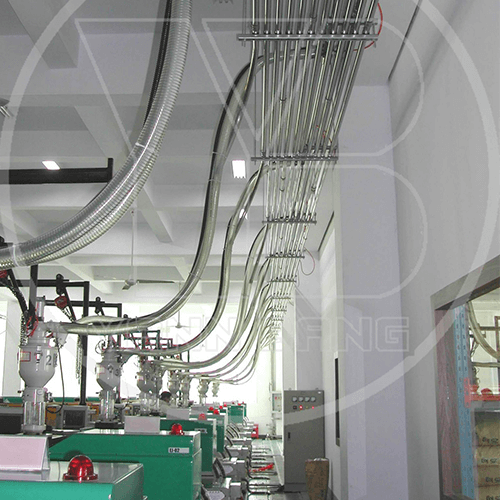

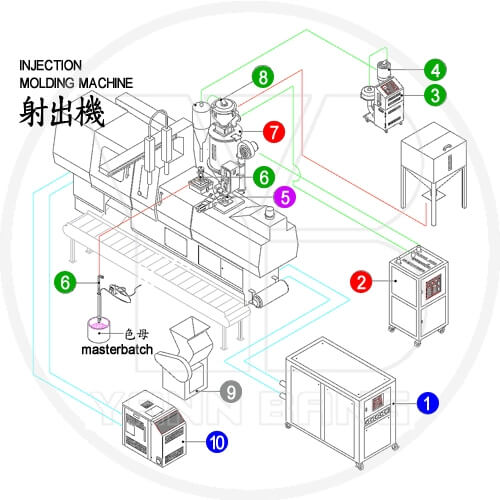

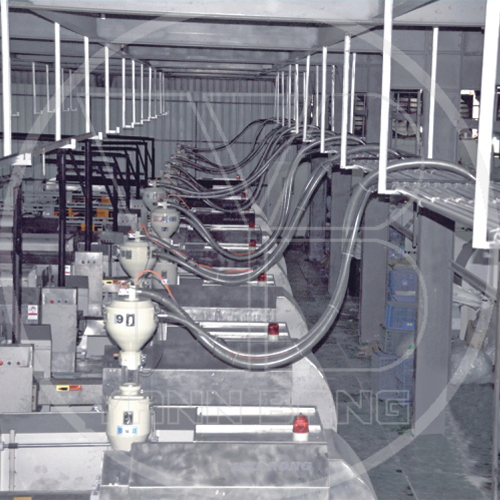

Our central vaccum conveying system also called centralized pneumatic supply system. It can be completely customized to your plastics processing to fullfill the target of continuous operation without downtimes.

One central conveying system can control 30 sets of molding machines at the same time and return on your investment in 2-3 years.

-

Better company image

-

Greater productivity

-

Lower cost

-

Better energy efficiency

-

Less material waste and pollution during the conveying process

-

Better working environment

-

Less noise due to the separation of the blowers from the working place

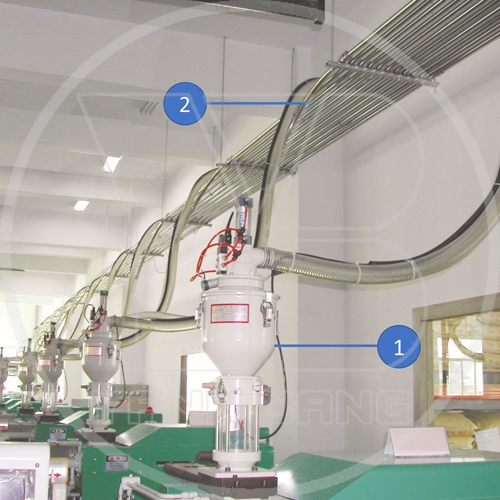

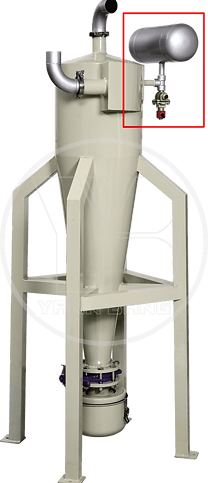

Suction Hopper

-

Standard Series (HS)

By negative pressure principle, convey the raw material into the hopper controlled by the limited switch.

-

Glass series (GS)

Fitted with a proximity switch to make the accurate control and the material supply easily observed. It can be mounted directly onto the molding machine and gives the operator a clear view of the loading through the sight glass.

-

Stainless Series for Optics (HS-S/GS-S)

The stainless suction hopper which is internal buffed is dust-free and best choice for optics industry.

-

Booster Series (HS-E)

Flexible Hopper design to increase or decrease your hourly capacity is economic and user-friendly.

-

Dust-Free Filter Hopper for optics (HDF)

During conveying, dust and resin are separated. To compare with other air filter, it can increase 300% efficiency to de-dust. Stainless design with transparent tempered glass gives a clear view of the loading, and it is perfect for optics need of dust-free.

-

Powder Series (HSP)

Working with a floor-type auto loader (TAE series) .It is the best choice for powder user. Available for powder, pellet or flake resin. Both new and recycled material are no problem. Special design to prevent dust and keep workshop clean. No longer worry about the powder jam at the bottom.

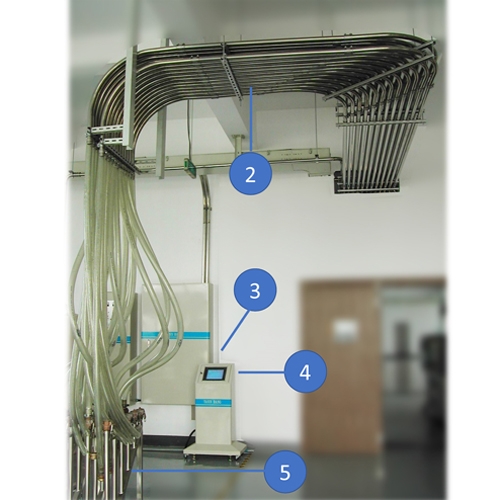

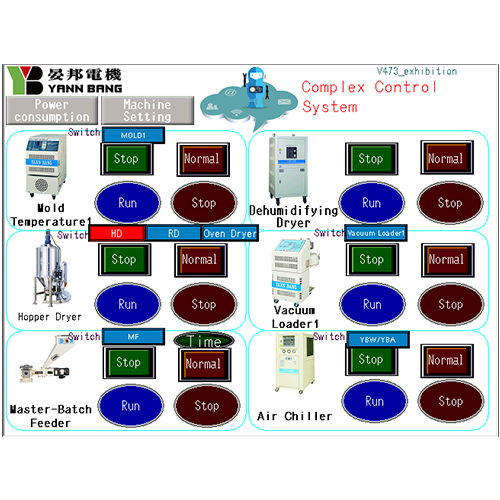

CMS Central Controller

1. One-of-kind design of integrating the monitoring panel and the control panel.

2. User-friendly interface and accurate control.

3. Operating and monitoring by a single personnel and can be linked with computer remote maintenance program to reach the most efficiency controlling mode.

4. Conveying time, material types, and pipe cleaning time of each station are adjusted by the control station.

5. Displaying panel shows you how each station, dryer, and storage silo work, such as on / off, full or lack of material, and material type of each station.

6. Extensive interface allows easy expansions up to 40 stations for future demands.

7. Compact and durable design.

Microprocessor Touchpad Controller

‧ Operating status : Display the operating status of units

‧ Set-up status : Display the set up status, such as working stations, material types, material conveying time, and pipe cleaning time.

‧ Abnormal : Display abnormal units and material types.

Option: Auto-cleaning device

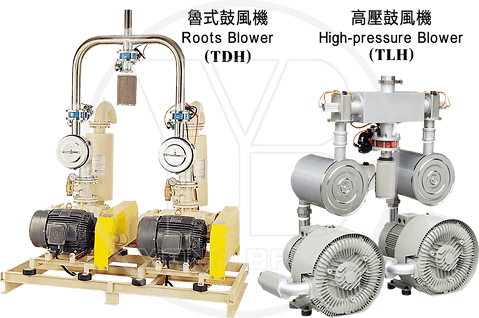

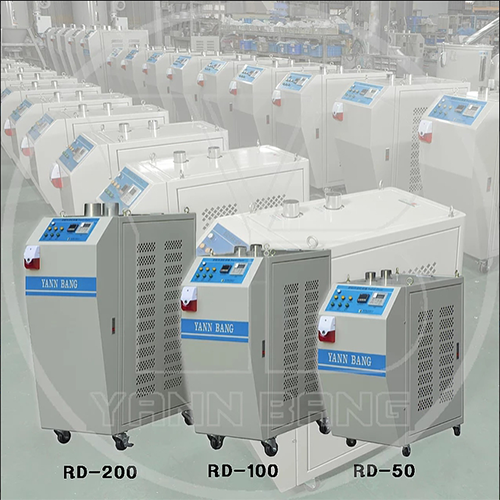

High-pressure Blower: short distance

Roots Blower: long distance