Reversible Rewinding Machine -FSR

Categories : Slitters and Rewinders

FSR Reversible Rewinding Machine is designed for rewinding operation of slit rolls, reels with uneven edge, or tension. Especially for rewinding on films with laminating paper, aluminum foil and other paper rolls after slitting. The FSR series also provide several flowcart satisfied the rewinding requirement for each different material.

Central Safety Filters

Categories : Loading and Conveying Machines

SCSF series central safety filter in central loading system adopts large dust collector to filter dust and small impurities in material so can effectively protect blower and prolong its service life. Self-cleaning function realize the effective cleaning of the filter by set-up auto timer, which can reduce manual clean times. Equipped with vacuum breaking valve to not only protect the blower, but also accelerate conveying and loading speed.

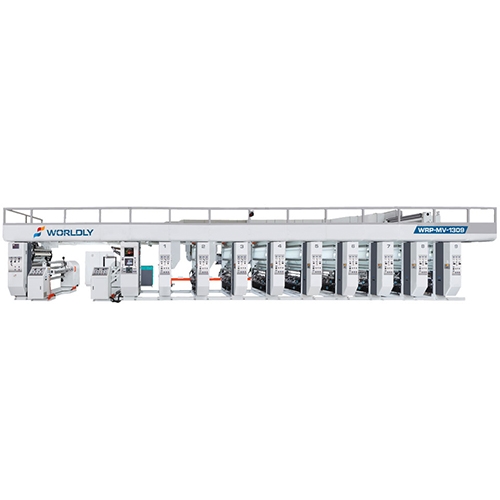

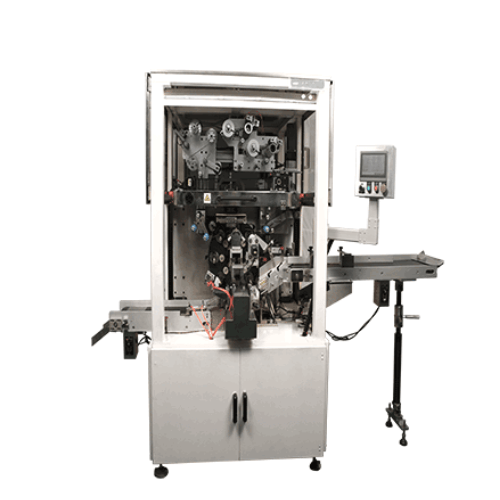

High Productivity Rotogravure Printing Machine(WRP-MV Series)

Categories : Rotogravure Printing Machines

Worldly company has good experience and technology development in new rotogravure machine over the years. The printing press equipment with powerful combination of central control system, and ease for operation. Simply and easily function and control parameter display on the human-machine interface touch screen, synchronized with PLC control system, also automatic alarm system provide the most efficient printing management for operators and leads to reduced default rates and less waste. Otherwise the exhaust recycle system can recycle the air up to 75% energy,The design leads to high productivity, lowers production costs, and provides a competitive advantage.

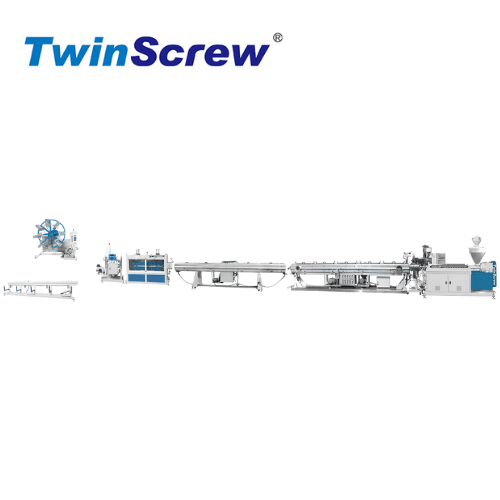

Co-Extrusion Two Layer HIPS/GPPS Sheet Extrusion Machine

Categories : Film and Sheet Extrusion Lines

Co-Extrusion Two Layer HIPS/GPPS Sheet Extrusion Machine

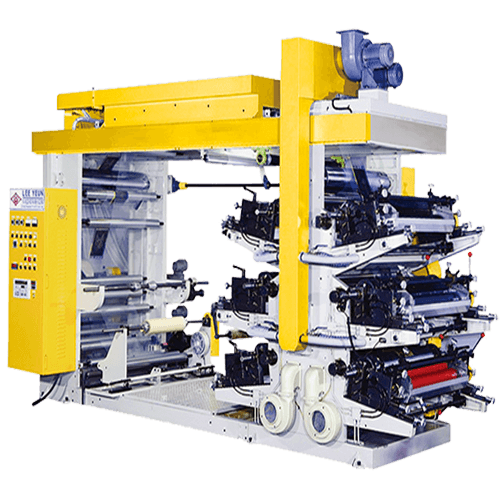

6 Color Offline Type Flexo Printing Machine: FSP-6000 Model

Categories : Flexographic Printing Machines

This is a higher grade flexographic printing machine than ll model, standard equipped with the japan original imported unwinding auto tension controller, and the hydraulic type edge position control (epc) system, double unwind and rewind station, let the operation more efficiency. Films go to the printing station with the banana roller to spread the films much even, and printing station with individually drying pipe providing the printed films for the primary drying, machine with t5 working light keep the working place very bright, upper side with overhead big drying chamber enlarge heating capacities cooperate with the blower ensure the films can be dried accordance with high speed.

Screenless Granulators - SG-14/24N/24T

Categories : Granulators

SG-14/24/24T series granulators operate in super low speed to cut materials into well-proportioned granules. There are least dusts produced in the cutting process. Multiple security devices ensure high safety grade; automatic reverse running function ensures continuous operation. This series of screenless granulators are suitable for granulating hard and thick materials. For SG-24T series, there are two gear motors and two cutting chambers to work simultaneously. It can not only granulate the sprues and waste material, but also has an effect on long and thin or tougher sprues materials.

HDPE high speed blown film line-twin head or single head

Categories : Blown Film Extruders

HDPE high speed blown film line-twin head or single head

Five Axes Servo Driven Robot - ST5-S2

Categories : Industrial Robots

The ST5 industrial robotic arm is designed for rapid and precise removal of sprue and products from injection molding machine, and place them at desired locations. Standard and telescopic arms are selectable to cooperate with 2 plate mold, 3 plate mold or hot runner system. Capable of arranging, stacking, quality checking and in mold placement. Suitable for injection molding machine under 3600T clamp force.

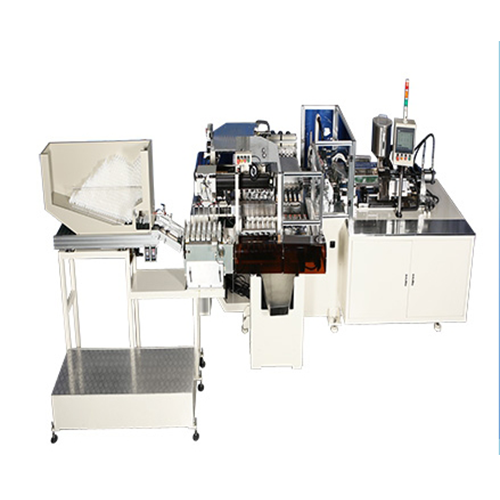

Soft Tube Injection Heading Machine RIH-60-06

Categories : Injection Molding Machines by Platen

Touch panel control.Suitable for both Oval and Round tubes production.Headed tube with orifice design available.Fully automatic controlling by servo motors: Loading/unloading system, Drillingorifice (option) , Cut head (option) , Orientation (option).Equips automatically loading conveyor with storage box.Four station indexing unit.

M6 Series Digital Melt Pressure Gauge - 4-20 MA Retransmission

Categories : Indicators and Sensors

The M6 Series has an improved digital readout utilizing an extra-large five-digit display. The M6 Series melt pressure gauge provides reliable, maintenance-free, localized pressure indication. The small capillary tube filled with a special medium isolates the gauge housing from potential thermal damage.

Single Screw Rubbing Drying Machine

Categories : Plastic Washing Line

With a powerful special designed single screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine).

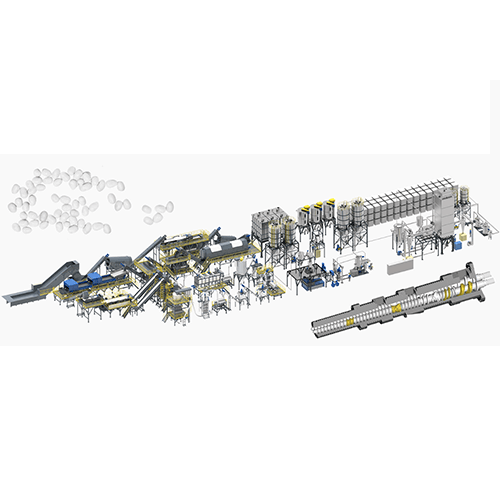

Bottle to Bottle Recycling Plant

Categories : Bottle Recycling Lines

Bottle to Bottle Recycling Plant

Corona Treater -T Series / For Blown Film Line

Categories : Blown Film Extruders

Corona treater is a surface modification technique for adhesion improving treatment and increase dyne level. It uses a low temperature corona discharge plasma to impart changes in the properties of a surface. Materials such as plastics, cloth, or paper may be passed through the corona plasma curtain in order to change the surface energy of the material. All materials have an inherent surface energy. Surface treatment systems are available for virtually any surface format including dimensional objects, sheets and roll goods that are handled in a web format. Corona treatment is a widely used surface treatment method in the plastic film, extrusion, and converting industries. It is also known as plastic surface treater, surface corona treater, air plasma, corona discharge treatment, corona treating, Corona-discharge Plastic Surface Treatment Equipment, corona treatment machine, corona treatment device and corona treatment. Application Extrusion: .Blown film extrusion / Blown film machine / ABA co-extrusion / Inflation machine .Cast film / sheet extrusion / Extrusion coating / coating lamination / Extrusion lamination / tandem extrusion lamination Printing: .Inline Printing press / printing machine / Rotogravure printing machines / woven bag printing / label printing / Solvent printing / water base printing / Flexo printing / T shirt bag printing Converting .Slitting rewinder / coating / wet lamination / dry lamination / hot lamination / solventless lamination / Rotogravure coating machines /gluing / bonding / tandem lamination Model CH-800S / CH-1000S / CH-1200S / CH-1500S / CH-2000S / CH-3000S / CH-5000S CH-800T / CH-1000T / CH-1200T / CH-1500T / CH-2000T / CH-2KT CH-3000T / CH-5000T / CH-8000T CH-3KT / CH-5KT / CH-8KT / CH-10KT / CH-12KT / CH-15KT / CH-20KT CH-3KD / CH-5KD / CH-8KD / CH-10KD / CH-12KD / CH-15KD / CH-20KD Substrate material HDPE, LDPE, LLDPE, MLLDPE, PET, PVC, PP, OPP, CPP, BOPP, PI, PS, PC, EVA, Nylon, PTFE, PU, TPO, TPE, TPO, Bio degradable , Biodegradable, Bio-degradable, Stretch film PE woven, PP woven Hollow profile sheet, corrugated sheet, Cartonplast, Polyflute, Coroplast , FlutePlast, IntePro, Proplex, Correx, Twinplast, Corriflute, Corflute Metalized film, FPC, Foil, copper foil, electrodepositedcopperfoil, CCL Non woven, Melt blown, Fabric, textile

Two Stage Force Side Feeding Plastic Recycling Machine (RECOi Series)

Categories : Plastic Waste Recycling Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

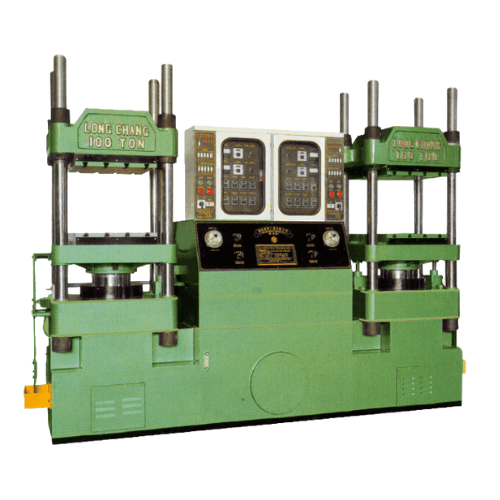

Twin Body Oil Hydraulic Compression Molding Machine - FB SERIES

Categories : Compression Molding Machines

APPLICATIONS: Bakelite, rubber, fiber, brake lining and any kinds of heated compression molding products.

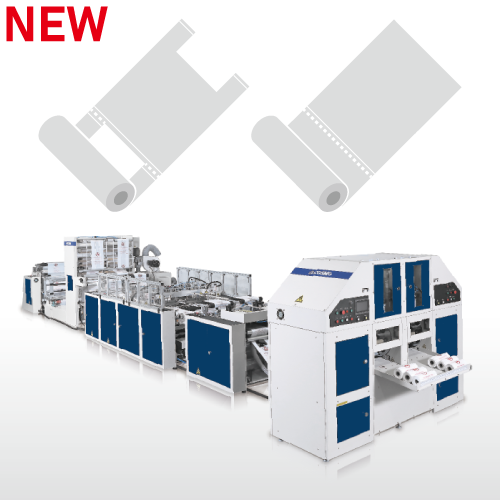

Fully Automatic High Speed 2 Lines with Core T-Shirt & Bottom Sealing Bags on Roll Making Machine with Slitting & Gusseting Unit-STBCR-40-G2+OS+2W

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatic film feeding, cordination free from tension adjustment Oscillation film feeding system for stability and high out put Automatically stop when running out of film / film feeding blocks or jam Automatically core changing system Punch system on magnetic roller

Plastic Tube Hot Stamping Machine HSM-50-01

Categories : Hot Stamping Machines

Touch panel control. Hot Stamping with servo motor control. Two colors of hot stamping are available. Automatic I-Mark registration. Automatic unloading conveyors for Good and NG products.

High Degree Water-type Mold Temperature Controller

Categories : Control Equipment

Economic and advanced design for high degree is your new choice. Water-type mold temperature controller (High Degree) do not pollute environment with oil gas that is the best choice for electronics, medical and cosmetic packing industries where strictly require better working environment. When oil-type model cannot satisfy for your need, you should change to water compression one. By direct supply method, it will not transform to steam even the temperature up to 160℃. Heat up faster, long machine life, high stability, precise control within ±0.3℃, and energy save for you. Precise temperature control and high stability control by 0.1℃ as a unit to display. The inaccuracy rate below ±0.3℃. Perfect for any precise requirement such as electronics industry. Heat-insulated design extend operating lifetime. PID temperature controller. Excellent overheat security protecting device. SSR relay control for durability. Unique design to prevent water leakage and pollution when mold is changed.