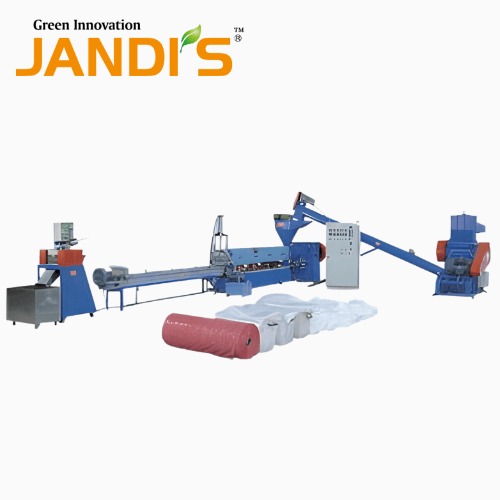

Water Cooling Type Plastic Film Recycling Machine (GSR-100)

Categories : Plastic Waste Recycling Machines

Water-cooled plastic film recycling machine GSR-100

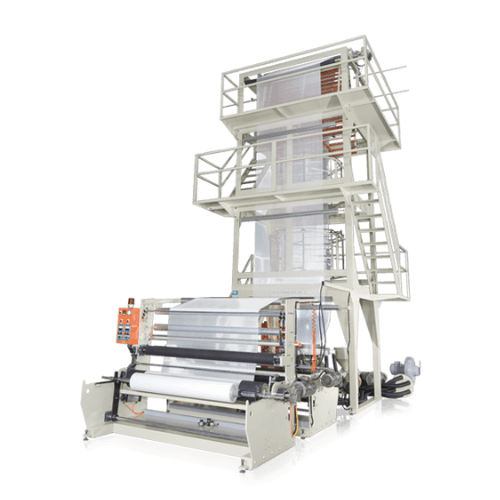

Multi-Layer Coextrusion Zipper Blown Film Machine (AEZ-3L)

Categories : Blown Film Extruders

MULTI-LAYER COEXTRUSION ZIPPER BLOWN FILM MACHINE

Three-Layer Co-Extrusion

Categories : Co-Extrusion Blown Film Machines

THREE-LAYER CO-EXTRUSION Blown Film Machine

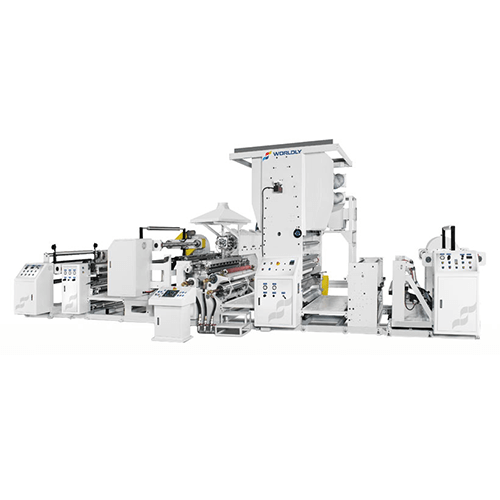

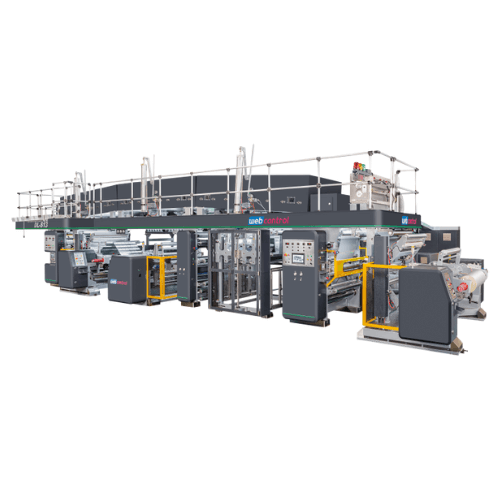

Mono Extrusion Coating & Laminating Machine (WEL Series)

Categories : Industrial Lamination

Worldly extrusion coating lamination machine is well-known in the flexible converting machinery from Taiwan. To cater most of low-waste packaging market our mono extrusion coating & lamination machine has very compact structure design. In order to save the wastage of web path & minimized the film threading time. The machine adopt leading brands T-Die to ensure the stable performance & constant high quality coating gauge, The screw and barrel has strict designed & treated to achieve well mixed of resin. Whole machine automation and tension with PLC control and all un/rewinders with nonstop turret auto splicing.The operation of the machine is very simple and user-friendly. The high speed version of mono extrusion coating & lamination machine adopted more advance equipment, such as auto air gap adjustment unit and auto water temperature control device. Those extra function allow to saving many operation procedure during the production. Thus the operator can be more concentrated on major operation and enhance the finished product quality.This type of machine is suitable for more high productivity demand.

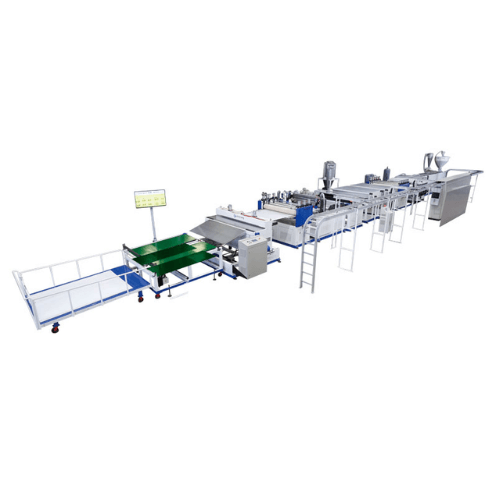

1600mm Wide , PP / PC Hollow Profile Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

For thirty years, Chi Chang has been designed and manufacturing fully computerised lines for sheet & film extrusion and co-extrusion. Our highly qualified team of engineers, operators and technicans has always been searching for high extrusion technology to meet your requirements. After years reserching since our first PP hollow profile sheet extrusion line in 1987, our new generation will produce PP hollow profile sheet with width from 1200mm to 2500mm, thinckness from 2mm to 10mm and output upto 500 kg/hr. In the mean time, we are pleased to introduce our new PC hollow profile sheet extrusion line. It is able to produce two-layer and three-layer PC hollow profile sheet with width 1200mm & 2100mm and thickness 5mm-10mm (two-layer) and 16mm (three-layer), and output upto 500 kg/hr.

Accumulator Double Head Blow Moulding Machines

Categories : Automatic Blow Molding Machines

Accumulator Double Head Blow Molding Machines Mono Layer and Multi-layer Accumulator Head Type Blow Moulding Machine. For producing 20 liter to 1000 liter volume, all kinds of jerry can, containers, air duct and industrial blow moulding products.

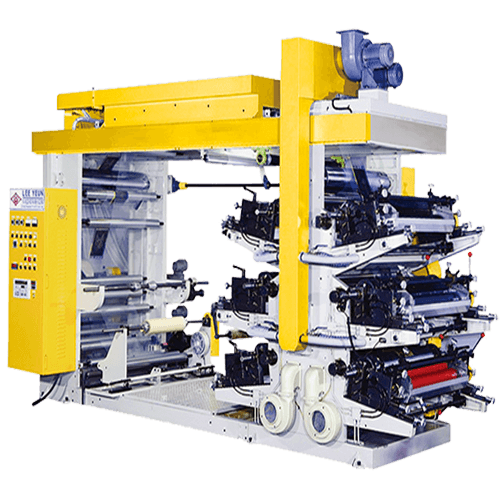

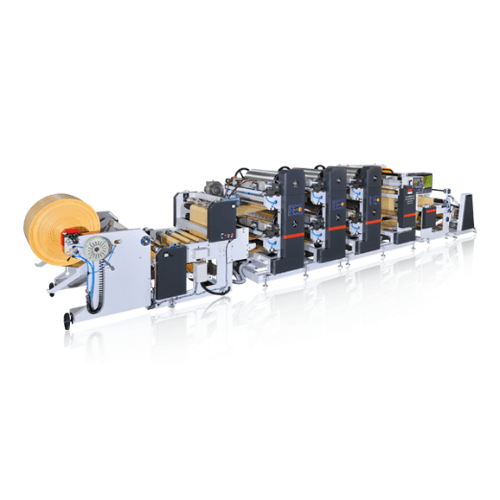

6 Color Offline Type Flexo Printing Machine: FSP-6000 Model

Categories : Flexographic Printing Machines

This is a higher grade flexographic printing machine than ll model, standard equipped with the japan original imported unwinding auto tension controller, and the hydraulic type edge position control (epc) system, double unwind and rewind station, let the operation more efficiency. Films go to the printing station with the banana roller to spread the films much even, and printing station with individually drying pipe providing the printed films for the primary drying, machine with t5 working light keep the working place very bright, upper side with overhead big drying chamber enlarge heating capacities cooperate with the blower ensure the films can be dried accordance with high speed.

Water Cooling Pelletizer Line (Vertical Force Type)

Categories : Plastic Pelletizer Machines

WATER COOLING PELLETIZER LINE(VERTICAL FORCE TYPE)

Seaming Machines K5 Plus

Categories : Shrink Sleeve Machinery

The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market.

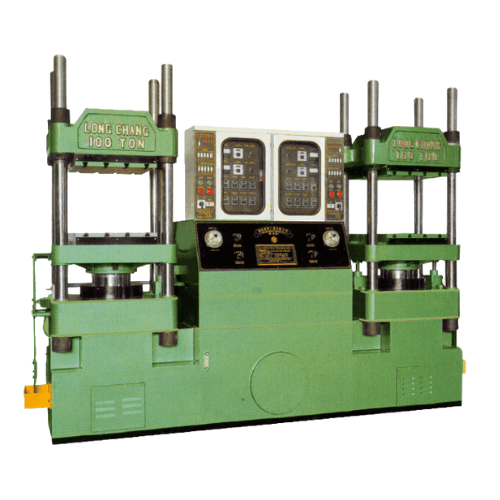

Twin Body Oil Hydraulic Compression Molding Machine - FB SERIES

Categories : Compression Molding Machines

APPLICATIONS: Bakelite, rubber, fiber, brake lining and any kinds of heated compression molding products.

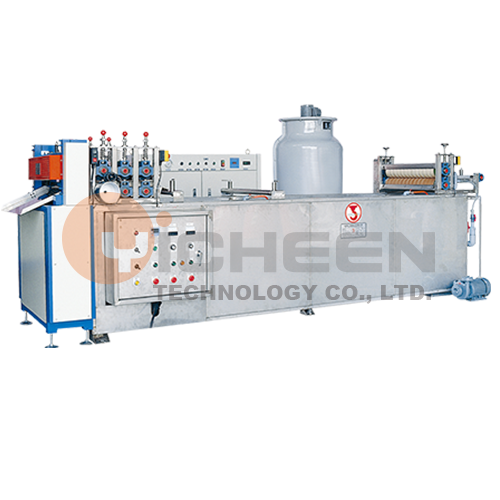

Rubber Cooling Machine (Water Type)

Categories : Rubber Cooling Machines

Application: Rubber, Silicone, EVA, Synthetic materials yicheen

Servo Motor Driven Double Layer Bag Making Machine

Categories : Plastic Bag Making Machines

1. Servo Motor Driven, Efficient mechanical structure produce 120 bags per minute. 2. User-friendly Control Panel, easy to understand easy to operate. 3. Digital control for production length adjusting, precise and less wastage. 4. Simple design, assemble precisely, durable, and easy for maintaining. 5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 7. Optional accessories: hot pin conveyor stack for T-Shirt bag making machine.

Controller

Categories : Control Equipment

Rubber Pellet Making Line: This KD pellet line is designed to provide automatically rubber pellet making line. It includes : Auto Weighting-->Mixing-->Extruding-->Pelletizing -->Cooling-->Screening& Storage. Features: This KD pellet line is designed to provide automatically rubber pellet making line. It includes : Auto Weighting-->Mixing-->Extruding-->Pelletizing -->Cooling-->Screening& Storage. Options: This KD pellet line is designed to provide automatically rubber pellet making line. It includes : Auto Weighting-->Mixing-->Extruding-->Pelletizing -->Cooling-->Screening& Storage.

Transfer Compression Molding Machine - FCSR Series

Categories : Compression Molding Machines

APPLICATIONS: Small rubber silicon products, rubber capacitor, golf ball.

T-shirt Bags Making Line for In-Line & Off-Line Operation (JIT-SS)

Categories : Bag Making Machine by Applications

- Produce Bio-Degradable Bags in a Greener Way - Power Required Reduced - Processing Waste Reduced - Production Mistake Reduced - CO2 Emission Reduced - Total Lead Time Reduced - Labor Cost Reduced - Recover Die-cut Material - Storage Space Reduced

Dry Laminating Machine Shafted Type DL-1000/1300

Categories : Industrial Lamination

This machine is for the Laminating process that uses a solvent-based adhesive. Reliable tension control with a mature lamination process able to make high-end products such as retort, sterilize and medical pouches. The gravure coating station allows high precision and consistency in coating weight. An efficient drying tunnel has high performance in vaporizing solvent completely to keep the product safe. Various options of heating solutions for drying tunnels are available. The energy-saving system is an option to help decrease carbon footprint and the cost of production

Zig-zag Separator

Zig-zag separator can effectively separate the dust in the flakes, small plastic labels or film by taking advantage of the gravity and the special internal structure design. The label aspirator separates the label and fine impurities from the flakes by the negative pressure which generated by blower, and can be used by multiple assembly.

Reel to Reel Flexographic Printing Line FSRP-6C (No Cylinder Changing)

Equipped Servo Motors for Precise Printing Graphic and Printing Length Control On-line Servo Control Printing Position Registration System (with Touch Screen Operation) (Each printing station equipped with servo motor to adjust printing position during machine running) Equipped with On-line Camera Inspection (Italy made) Two Units, Monitoring Printing Quality during Machine Running. Equipped with Doctor Blade System and Ceramic Anilox Roller as Standard Equipment

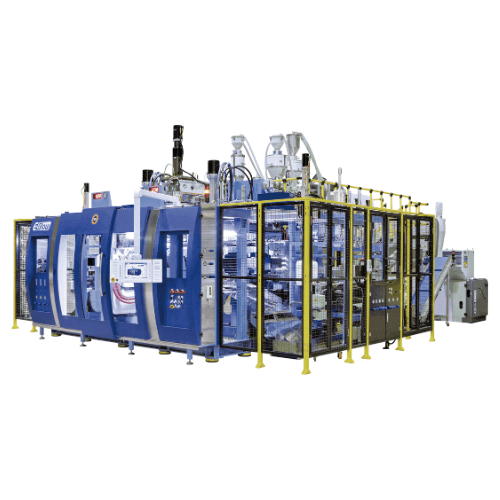

All Electric 3 Layer, Double Station Blow Moulding Machine for Plastic Bottle Making

Categories : Electric Blow Molding Machines

All Electric 3 Layer, Double Station Blow Moulding Machine for Plastic Bottle Making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system.

High Speed Side Sealing Chicken Bag Making Machine with Servo Motor Control Model: CWSS+C+SY-500-SV

Categories : Plastic Bag Making Machines

High Speed Side Sealing Chicken Bag Making Machine with Servo Motor Control Model: CWSS+C+SY-500-SV

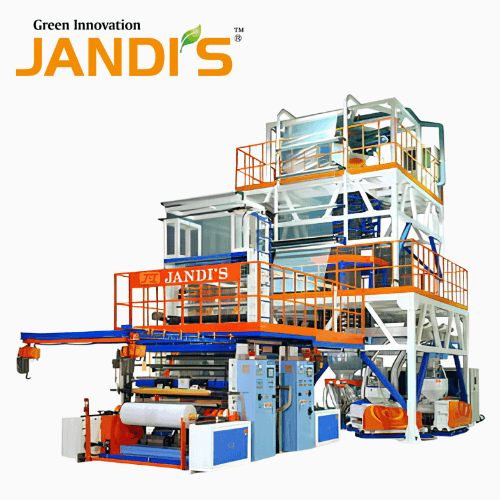

3 Layer Co-Extrusion Inflation Machine (GF-L3C-MT)

Categories : Blown Film Extruders

3 Layer Co-Extrusion Inflation Machine (GF-L3C-MT)