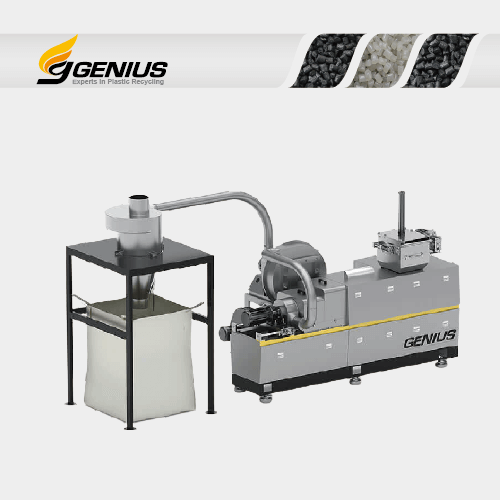

KRS Air Cooling Recycling Machine

Categories : Plastic Pelletizer Machines

In the process of manufacturing plastic film, recycling is a vital step. In order to save production costs and create more profit, many manufacturers are recycling their in-house materials. The KRS Air Cooling Recycling Machine is specifically designed to process edge-trimmed recycling from PE bag production line. It can recycle light printed plastic films into homogenous and high-quality pellets. In most cases, 100% of the recycled pellets produced by KRS can be reused in products production line.

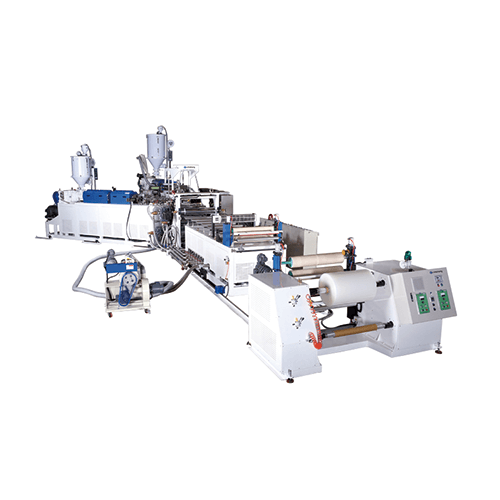

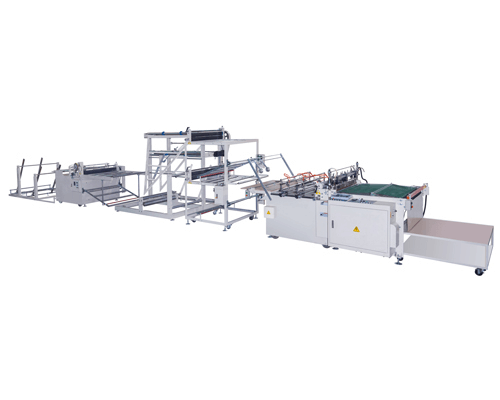

Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

Mono-layer and Multi-layer Sheet Extrusion System for up to 5 layers Versatile and reliable downstream equipment Complete Sheet Extrusion Line with extruders 55-200 mm Processing Capabilities: ABS, PE, PP, PS, PET, PC, PMMA, and other thermoplastic materials.

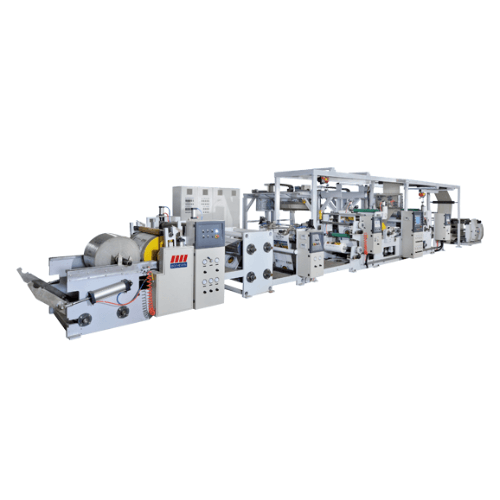

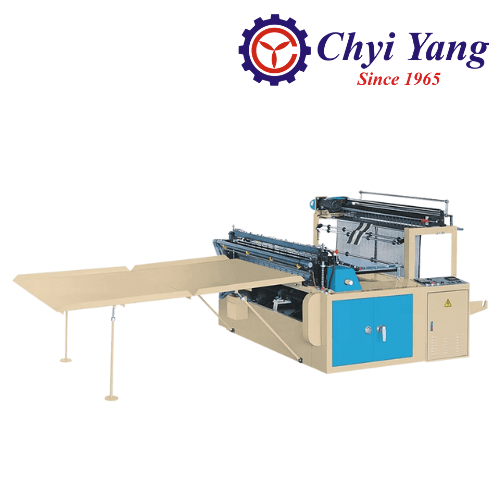

Center Seal and Gusset Machine-FK-N

Categories : Plastic Bag Making Machines

This machine is well suited for producing thick and multi-laminate film such as poly bags with center sealing and side gusseting. When combined in operation with FSC-303 Three Step Bottom Sealing and Cutting Machine, it provides the same function as an in-line model Center Seal and Gusset Bag Making Machine

Shrink Sleeve Width Measuring -Sleeve Eye

Categories : Shrink Sleeve Machinery

Sleeve Eye inspection system is designed exclusively for in line inspection of shrinkable label. It is capable of detecting lay flat width with ultrasonic system right after seaming process. Sleeve Eye inspection system is very versatile and it can also be installed on other machinery such as seaming machine and rewinding machine. Operators can now perform width inspection without the use of ruler. Simply enter the upper and lower limits of the width specifications, the system will alarm once out of limits situation occurs. Consequently, the operator can take appropriate remedial actions to improve product performance.

Fully Automatic High Speed 2 Lines with Core Vegetable Bag-on-Roll Making Machine with Hot Slitting & Side Gusseting Unit / SCR-40-G2

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatic film feeding, cordination free from tension adjustment Automatically stop when running out of film / color scanning error / film feeding blocks or jam Automatically core changing system Hot slitting device

Corona Treater - High Speed THH-2H

Categories : Surface Treatment Equipment

Corona treater for Printing purpose, features Output 8~20 kw Treat width 1000~3000 mm Speed 100~300 m/min. 2 side treatment 38-46 dyne Apply to inflation, lamination,printing, cutting application Stainless discharge 12 steps

Horizontal Mixer / Blender (YBHM)

Categories : Mixers and Blenders

Mixing quickly and evenly with motor overload protector and power safety device. It is safe and easy to operate. The mixing capacity could be extended to one ton. The mixing barrel can be tilted freely at the angle degrees for discharge and maintenance.

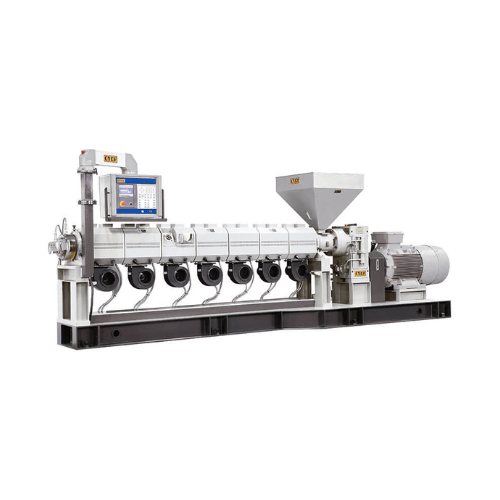

High Output Single Screw Pelletizing Extruder | CK-DHS

Categories : Plastic Pelletizer Machines

CK-DHS series Single Screw Extruder has the fastest screw rotational speed and highest throughput among all single screw series. It equipped with high-efficiency gearbox which is capable of bearing greater back pressure and torque force during production. The low-noise and durable gearbox is adjustable to satisfy different production conditions. Possible materials : ABS, HIPS, PP, PE, PC&ABS, PC. PMMA.

Strand Pelletizer

Categories : Plastic Pelletizer Machines

CYKF self-made strand pelletizers are able to handle most kinds of plastics. The strand pelletizers can cut cylindrical plastic strands into even pellets. In order to response different demands on capacity, CYKF develops 5 models for choice. The modular design can easily fit into any existing production lines to immediately support production. Moreover, we provide the complete product range for strand pelletizer, including water tank, strand dryer, vibrating screen and storage tank. The comprehensive service saves time as well as solves troubles on system integration. All equipment is designed and manufactured by CYKF which guarantees the quality of the products. Currently the CYKF strand pelletizers are widely used in polymer, recycling, chemical, electronics, automobile, and food industries, etc. The stable operating performance and long service life earns good reputation from customers, and the excellent features have already made contributions to lots of industries in the world.

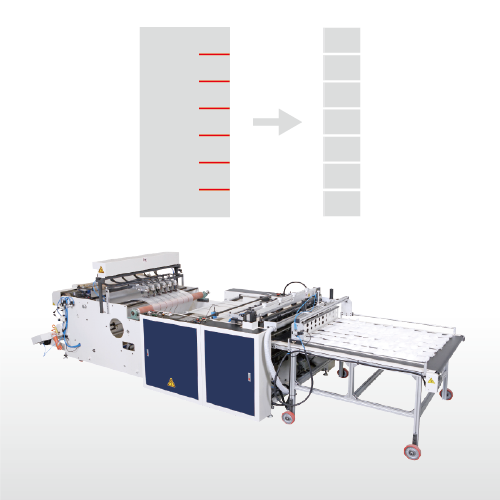

Fully Automatic Bottom Seal Bag Making Machine with Hot Slitting System-SE-40S/50S

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Servo motor, as standard attachment, makes it easy easy to adjust the bag length and production speed Automatically stop when running out of film / film feeding blocks or jam / scanning error

Three Side Sealing Bag Making Machine(YSW-EM-3)

Categories : Plastic Bag Making Machines

• Servo motor control minimizes length tolerance ensure high efficiency and accuracy. • Using Plugging type IC circuit for easy replacement.

6" Plate-EG-6

Categories : Containers

Product Number: EG-6 Color: Natural Material: Fiber Shape: Round

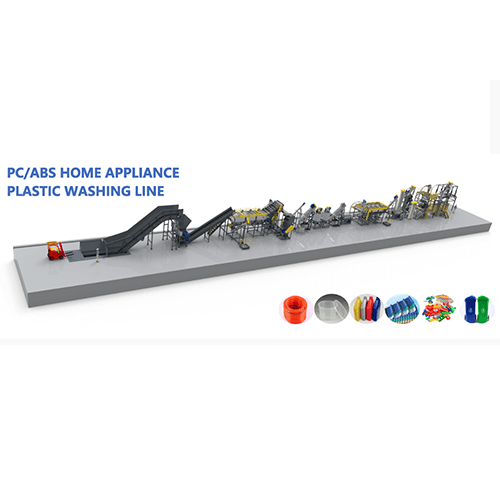

Rigid Plastics Recycling System

Categories : Plastic Waste Recycling Machines

Rigid Plastics Recycling System

Insert Injection Molding

Insert Injection Molding Technology is a manufacturing process that integrates pre-placed components, such as metal inserts, electronic parts, or other materials, into a plastic injection mold. During molding, molten plastic encapsulates the insert, creating a single, durable, and high-precision component. This technology enhances product strength, reduces assembly costs, and improves reliability, making it widely used in automotive, electronics, medical devices, and consumer products. By ensuring strong adhesion between plastic and inserted components, insert injection molding enables lightweight designs, enhanced durability, and improved performance in various applications. Key Advantages: Seamless integration of metal and plastic components Higher product strength and durability Cost-efficient by reducing assembly steps Customizable for complex geometries Enhanced precision and consistency Common Applications: Automotive Parts – Armrest trim panels, dashboard components, connectors Electronic Components – Connectors, circuit boards, protective casings Medical Devices – Surgical tools, sensor housings, implantable components Consumer Goods – Power tool grips, ergonomic handles, durable casings

NO TENSION TYPE PLASTIC BAG MAKING MACHINE

Categories : Plastic Bag Making Machines

Suitable for large or thick bags production. This machine is no-tension, the sealing won’t be pulled Optional servo drive for accurate length control. Automatically stops if any bag is squeezed and an alarm will sound. We didn’t show all specification & model, please kindly contact us for other model & details specification

Heavy Duty Model Dispersion Kneader

Categories : Dispersion Kneaders

Compounding For Rubber、Plastic & Chemical Industries

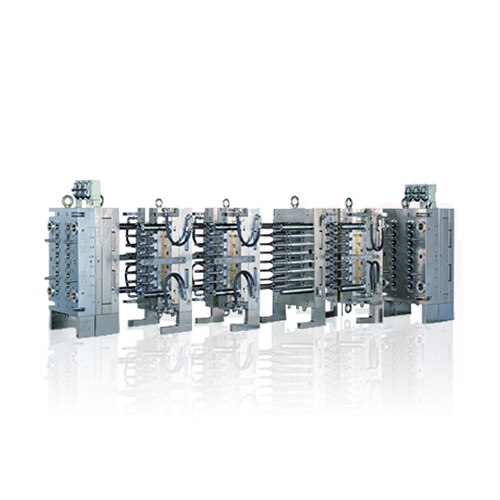

Preform Injection Molding Molds

Categories : Injection Molds

Professional PET injection molding machine. Whole plant export includes know-how Special use extrusive screw. High mixes for PET plasticity. Digital control system uses 4 CPU computer systems. Heat treated stainless steel molds for a long service life - guaranteed 2 million times. Japan SEIKI hot runner, air valve, and auto temperature control. Double circuit negative pressure chiller. Technical consulting service is available by request.

Stepper-Controlled Proportional Valve 0-400L/min

Categories : Separators

Product Serial: FC-300+PM-300 Proportional Flow Control Valve consists of PM series driver and FC series proportional flow valve. With an input signal either through analogue or digital, the needle inside the proportional valve moves proportionally to the signal. This series is able to control the flow rate of air and liquid with high resolution, high accuracy, and high repeatability. It is developed for industries that require a high degree of adjustment in flow rate. Series PM driver provides series FC valve with the required power and control signal (step and direction). It controls the step of a bipolar stepper motor with an analogue signal (0-10 VDC/4-20mA/RS485 Modbus).

Additive - TX Series

Categories : Industrial Adhesives

Ever Polymer has the mission to satisfy all the application needs for thermoplastic elastomers (TPE) raw materials in the market. TPE TPR tpe material tpe material eco friendly tpe material manufacturer tpe material properties tpe material toxic tpe plastic recycling tpe raw material tpe rubber what is tpe material tpe material safety